68

30AW

Coil heating control (compressor warm up process)

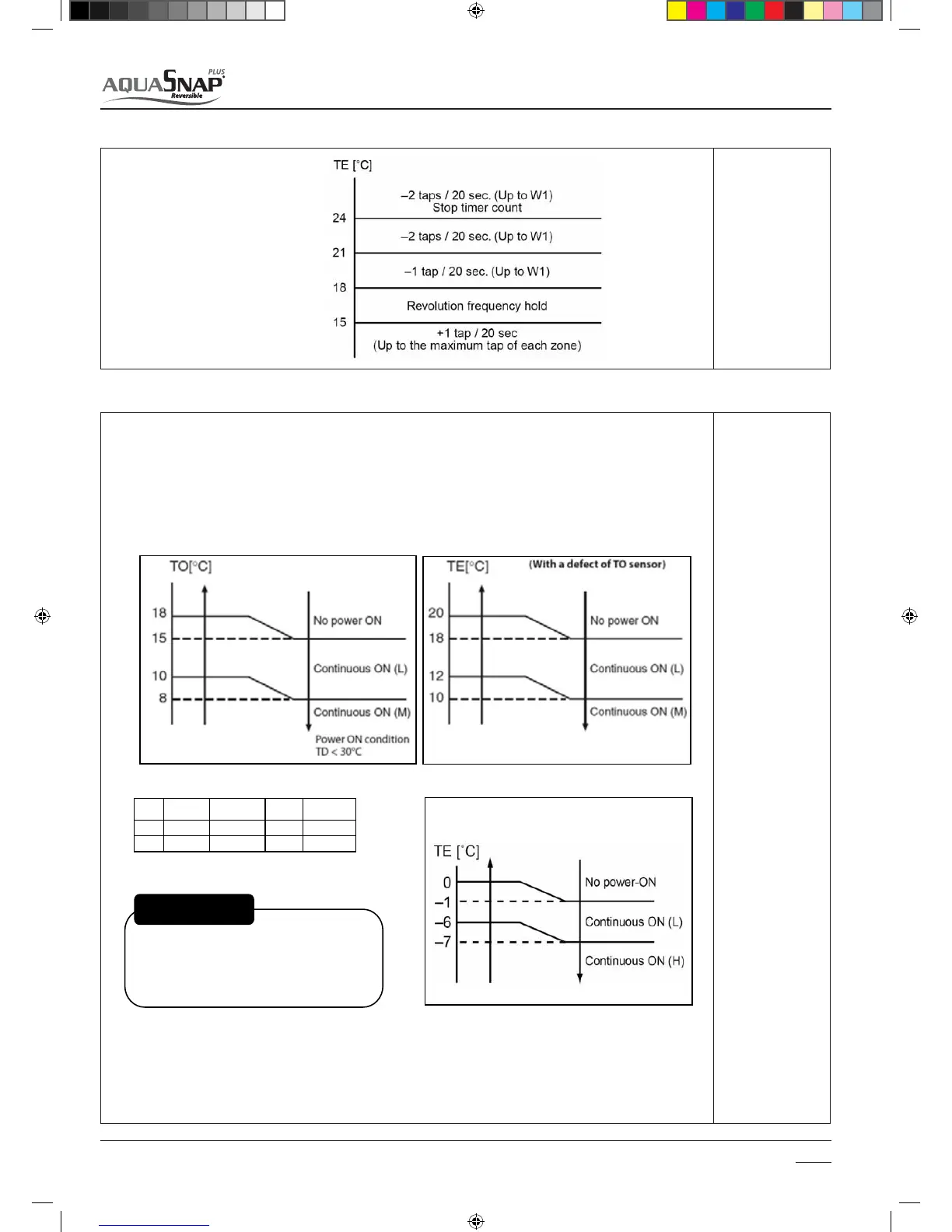

5IJTDPOUSPMSPVUJOFNBJOUBJOTTVóDJFOUMZIFBUFEUIFDPNQSFTTPSTUPQQFECZQPXFSJOHPOUIFXJOEJOHTJOTUFBEPGB

crankcase heater. The control purpose is to prevent slackness of refrigerant inside the compressor.

5PBWPJEDPNQSFTTPSEBNBHJOHEVSJOHUIFJOTUBMMBUJPOUFTUNPEFPSBGUFSMPOHDPNQSFTTPSPòUJNFJUTBEWJTFEUPTUBSU

the system when the control has interrupted the compressor warm up process.

3. A judgment for electricity is performed by TD and TO sensors. In the event of TO sensor failure, a backup control is auto-

matically performed by TE sensor (judging the TO sensor defect checking the outdoor LED display).

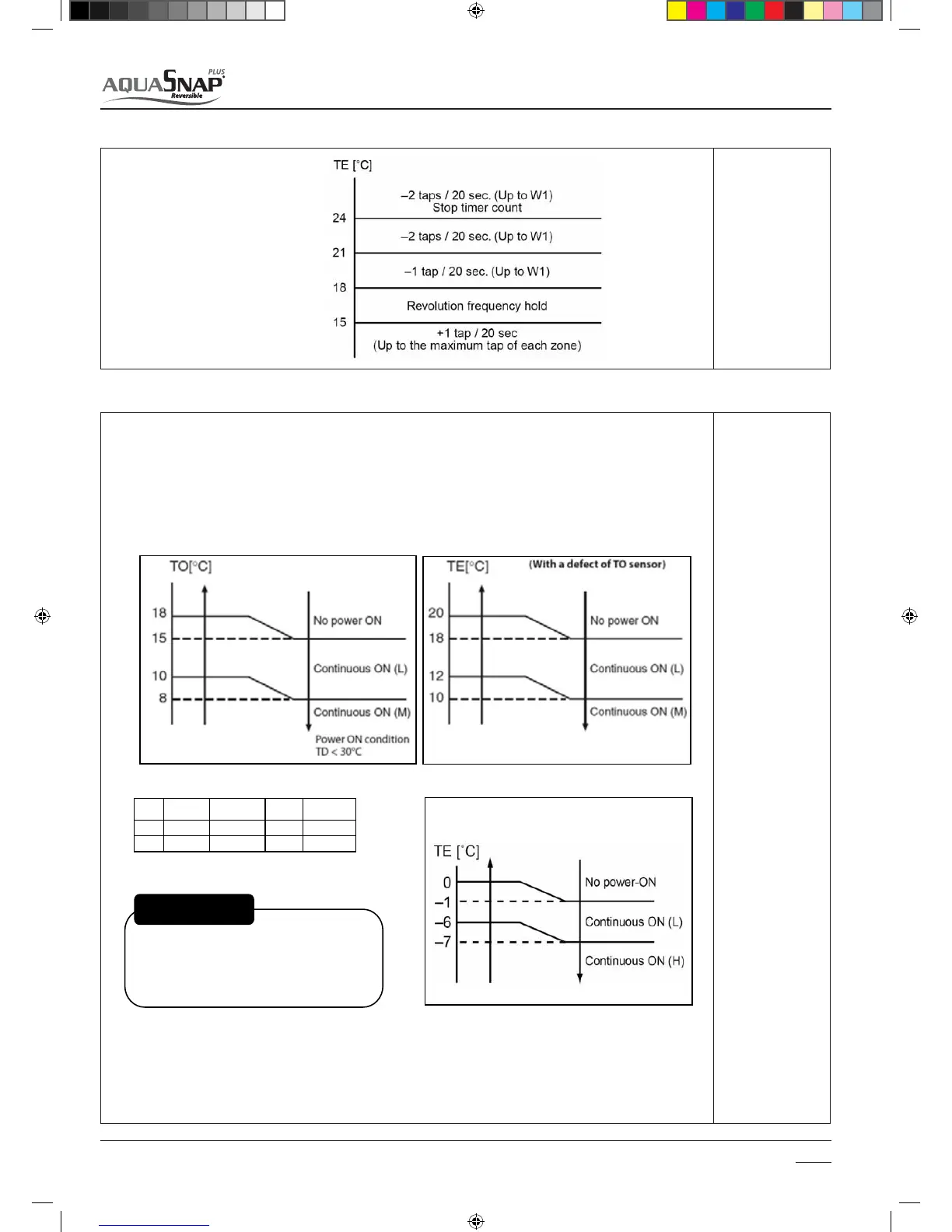

4. The right coil heating is controlled by TD and TE sensor.

'PSFBDINPEFMUIFDPNQSFTTPSXBSNVQQSPDFTTJTJOUFSSVQUFEUVSOJOHPòUIFQPXFSTVQQMZXIFO5%JT¡$PSNPSF

008 size

004 006-008 012 015

L 10W 10W 25W 40W*

M 30W 30W 50W 40W

It is not an abnormal phenomenon

that electro-noise may be heard

while heating the coil.

NOTIFICATION

JOUFSNJUUFOUQPXFSPONJOVUFTPONJOVUFTPò

TO: Outdoor

Temperature

TE: Entering

(in Heat

exchanger)

temperature

TD: Discharge

temperature

Control management

5

SM_30AW.indd 68 14-03-2011 14:45:17

Loading...

Loading...