56

30AW

Control management

5

5.1 Introduction

5.2 Unit Control

USER INTERFACES

GMC CONTROL

INVERTER CONTROLLER

Users can select the desired operating

NPEFUISPVHIEJòFSFOUSFNPUFDPOUSPMMFST

Control is based on the GMC platform developed by Carrier. For the

30AWH AquaSnap PLUS inverter chiller / heat pump a new GMC board

has been developed as well as new algorithms have been implemented.

The GMC control elaborates the request from the user interface and

translates it into a message for the chiller unit control. It continuously

analyzes the water, indoor ambient conditions and the customer

requests sending updated signals to the chiller unit control.

The chiller unit control takes care of the system reliability and satises

The main ow of logic in this control is as follows: The control reads

in inputs from discrete inputs, analog inputs, communications. These

inputs are then processed by mode control. After the mode control

comes the protections that protect the unit from damage. After the

protections, the outputs are energized or de-energized. Then the loop

repeats itself.

High voltage communications is used to communicate from the GMC

the requests coming from Inverter control tuning chiller unit fan, PMV,

compressor.

The chiller unit control continuously sends back signals to the Inverter

control.

board to inverter control.

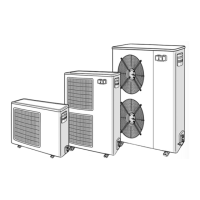

Maximum values are maximum compressor frequency allowed unless

limited by a protection or message received from the User Interface.

The User Interface can limit the maximum compressor frequency from

UP

A2W

Size

Inverter

Capacity

(kW)

GMC Control

returned to Inverter

(HP)

Minimum

Cooling

(Hz)

Maximum

Cooling

(Hz)

Minimum

Heating

(Hz)

Maximum

Heating

(Hz)

4 4 1,25 20 90 20 95

6 6 1,75 10,2 100 10,2 104

8 8 3 10,2 82 10,2 104

1212 5 15651560

15 15 6 10,2 65 10,2 70

SM_30AW.indd 56 14-03-2011 14:45:05

Loading...

Loading...