15

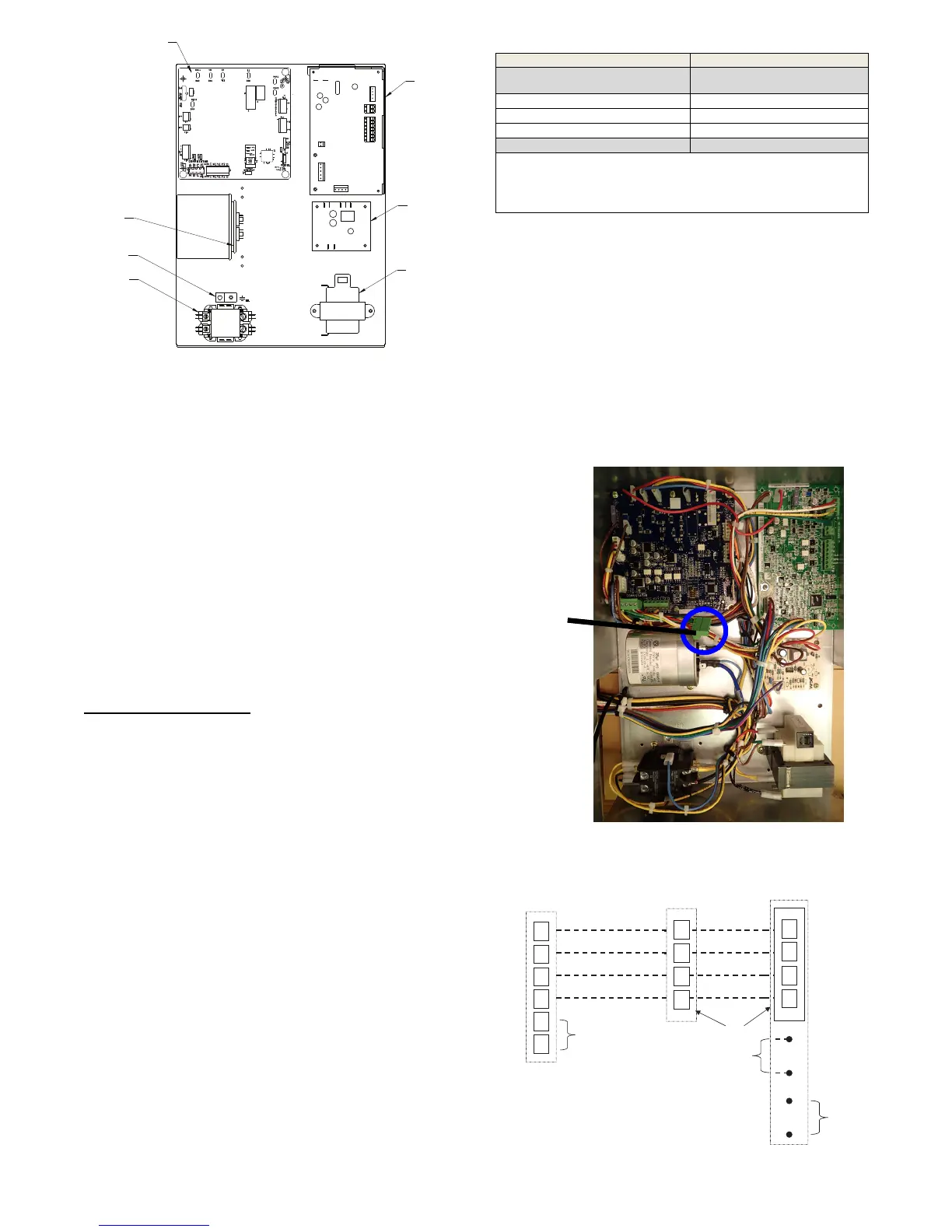

CIRCUIT BOARD

RUN

CAPACITOR

GROUNDING

LUG

CONTACTOR

2-POLE 2-THROW

TRANSFORMER

208/230 75VA

CONDENSATE

BOARD

FAN

BOARD

A150554

Fig. 16 -- Electrical Component Box Layout

ELECTRONIC THERMOSTAT

INSTALLATION

Field Connections

This section is intended as a quick reference only and should not

replace a complete review of thermostat Installation Instructions.

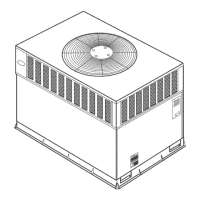

The GC unit can be installed as communicating with UI

communicating thermostats only.

Communicating

User Interface (UI) is designed to self-- program with the the GC

unit when connected to the unit bus com harness ABCD connector

(refer to Fig. 17) with the ABCD male adapter included with the

unit in the literature packet shipped with the unit. 4 wires are

needed as the bus com harness communicates between both unit

boards and the UI when connected.

NOTE: Field wiring only needs to go to UPM and connector as

the boards have factory wiring between them.

NOTE: It is advisable to run extra thermostat wire during

installation in the event of faulty wires, etc.

Communicating System T

ips:

SThe GC units include an Outdoor Air Temperature (OAT) sensor in

the literature packaging. Refer to Table 5 for thermostats that can

incorporate this OAT and the thermostat instructions for wiring.

SThe GC unit must be used with Wall Control version 13 or newer

software for communicating connections.

SThe Energy Tracking Kit (KHAGT0101KIT) includes a sensor and

wiring harness. The kit must be installed on the geothermal unit for

energy tracking functionality.

SWi--Fi capability will be available with the Wi--Fi Wall Controls

SYSTXCCITC01, SYSTXCCITW01, SYSTXBBECC01,

SYSTXBBECW01.

STo enter the Wall Control service mode hold the service cap in the

main menu for about 10 seconds until it turns green then release.

SThe last 10 system faults can be found in the service screens. Flash

codes on the UPM board flash only an active code with series of

short and long flashes on the amber LED. A code 37 will appear on

the UPM LED as 3 short flashes followed by a pause then 7 long

flashes followed by another pause and repeats this series. The Wall

Control will display text on the screen for the last 10 events.

SExit service screens by selecting ”Done”.

Table 5 – Recommended Thermostats

Carrier Systems: Bryant Systems:

Infinityr To u c h

Wall Control

Evolutionr Connex™

Wall Control

SYSTXCCITC01* SYSTXBBECC01*

SYSTXCCITW01* SYSTXBBECW01*

SYSTXCCITN01* SYSTXBBECN01*

* Version 13 or newer software

The GC unit is shipped with one OAT sensor in the literature package:

TSTATXXSEN01--- B

Note: Any of the model numbers above may be followed by a revision

letter such as ”---A”.

Non--Communicating (Emergency Mode Only)

Temporary Emergency Electric Heat Mode in Event of UI

Failure

In the event the system UI fails after initial UI install and there is a

need for heat while a replaceable UI can be obtained, these steps

can be followed with a non--communicating thermostat to provide

electric heat only temporarily .

The ECM board non--communicating stat connections can be

wired with a non--communicating thermostat to provide emergency

electric heat temporarily by connecting only C, W, G and R.

Disconnect the bus com harness ABCD connector to the ECM.

Do NOT wire the Y as the programming in the UPM will not allow

cooling or heating mode.

System is not to be left in this configuration for an extended

period, UI must be replaced as soon as possible.

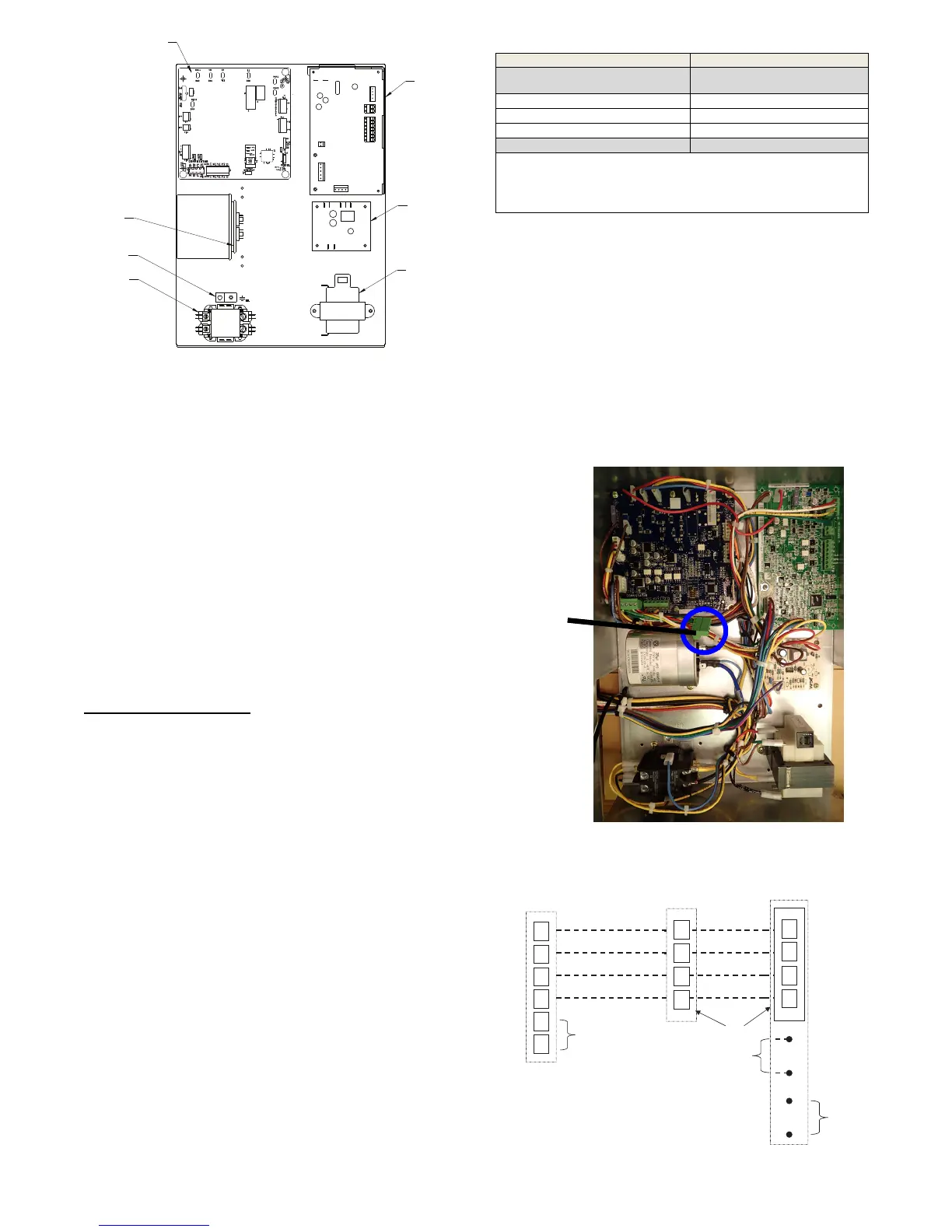

BUS Com

ABCD Field

Connection

BUS Com

ABCD Field

Connection

A150781

Fig. 17 -- ABCD BUS COM Connection

A

B

C

D

Communicating System

Wall Control

Green - Data A

Yellow - Data B

White - COM

Red - 24VAC

Optional Remote

Room Sensor

S2

S1

ABCD

Connections

ECM

A

B

C

D

UPM

Humidifier

Connection

OAT

Sensor

(Optional)

A

B

C

D

OAT

HUM

COM

24V

White - COM

Red - 24VAC

Green - Data A

Yellow - Data B

A150168

Fig. 18 -- Universal Connection

Loading...

Loading...