39

Systems Communication Failure

If communication with the compressor control is lost with the

Communicating System Wall Control, the control will flash the

appropriate fault code (see Table 14) to the rest of the

communicating system, including the wall control and the indoor

geothermal unit.

Model Plug

Each control board contains a model plug. The model plug is used

to identify the type and size of unit to the control.

The correct model plug must be installed for the system to operate

properly (see Table 16).

Table 16 – Model Plug Information

Model

Number

Model Plug Num-

ber

P I N S 1 --- 4 PINS 2--- 3

GC024 HK70EZ006 5.1K 51K

GC036 HK70EZ007 5.1K 62K

GC048 HK70EZ008 5.1K 75K

GC060 HK70EZ009 5.1K 91K

GC072 HK70EZ010 5.1K 120K

On new units, the model and serial numbers are input into the

board’s memory at the factory. If a model plug is lost or missing at

initial installation, the unit will operate according to the

information input at the factory and the appropriate error code will

flash temporarily .

NOTE: RCD replacement boards contain no model and serial

information. If the factory control board fails, the model plug must

be transferred from the original board to the replacement board for

the unit to operate.

NOTE: The model plug takes priority over factory model

information input at the factory. If the model plug is removed after

initial power up, the unit will operate according to the last valid

model plug installed, and flash the appropriate fault code

temporarily.

Troubleshooting the Model Plug

If the unit is being identified incorrectly by model or size, verify

the plug resistance per Table 16. If resistance value verifies the

plug is good, ensure the plug is dry and condensate free.

NOTE: Dielectric grease (field supplied) can be used on model

plug pins if condensate has been noted after drying the plug.

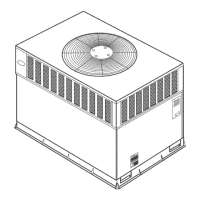

Service Tool

(A+B) Communication

(C) Common

(D) 24 Vdc

A150782

Fig. 29 -- Service Tool Connection

When working on the outdoor unit of a package system, the

technician would usually need to repeatedly walk between the

indoor wall control and the unit outside. To save time, the

communicating controls offer a service tool feature.

By wiring the service tool into the UPM board, the technician can

have a wall control capable of running the system right at the

outdoor unit.

To use a service tool, connect the A and B communication bus

wires from this second communicating control to the terminals

marked A and B on the terminal strip located in the bottom left

corner of the UPM board (see Fig. 29). But instead of connecting

the wires on the service tool to the terminals marked C and D,

connect the C and D wires from the service tool to the 24V and C

on ST1 as shown in Fig. 29.

When the service tool is connected and powered up, the

communicating controls inside the home will ”go to sleep” and let

the service tool take control of the system. In this manner, the

service technician can run the diagnostic checkouts right at the

outdoor unit using the service tool.

After the checkouts are completed and it is no longer necessary to

use the service tool, remove it from the communicating controls

and the indoor communicating controls will regain control in about

two minutes.

CAUTION

!

UNIT DAMAGE AND/OR OPERATION HAZARD

Failure to follow this caution may result in unit damage

and/or improper equipment operation.

Connect 24 across COND and COMMON on ST1

thermostat connections. Ensure condensate overflow wires

remain connected for proper protection.

Loading...

Loading...