7

A quenching cloth is strongly recommended to prevent scorching

or marring of the equipment finish when brazing close to the

painted surfaces. Use brazing alloy of 2% minimum silver content.

Refrigerant gas may produce toxic gas if it comes into contact with

fire (as from a heater, stove or cooking device). Exposure to this

gas could cause severe injury or death.

Applying too much heat to any tube can melt the tube. Torch heat

required to braze tubes of various sizes must be proportional to

the size of the tube.

Service personnel must use the appropriate heat level for the size

of the tube being brazed.

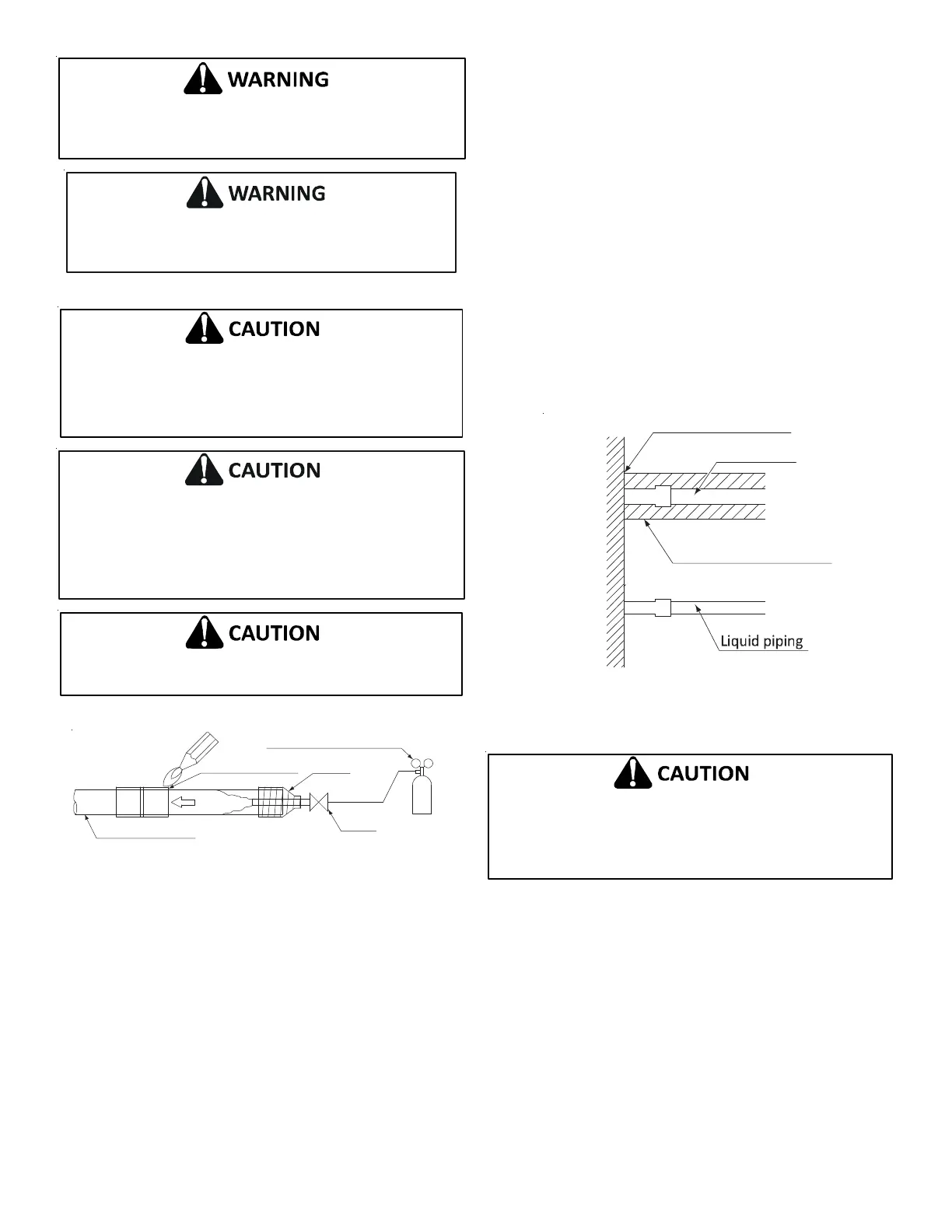

When brazing the refrigerant piping, perform nitrogen

replacement first or perform the brazing while feeding nitrogen

into the refrigerant piping. See following figure.

When brazing pipes while feeding nitrogen inside the piping,

make sure to set the nitrogen pressure to 2.9 PSI or less using the

pressure reducing valve.

Use of oxygen could result in an explosion resulting in serious

injury or death. Use only dry nitrogen gas.

Refrigerant piping

Part to be brazed Taping

Pressure-reducing valve

Hands

valve

Nitrogen

Nitrogen

Figure 9

NOTE: Do not use flux when brazing refrigerant piping. Therefore,

use the phosphor copper brazing filler metal (BCuP) which does

not require flux. Flux has an extremely negative effect on refriger-

ant piping systems. For instance, if chlorine based flux is used, it

will cause piping corrosion. Flux containing fluorine will damage

refrigerant oil.

8.5 Re-assemble the Coil and Controls

• Once heat from the brazed area has dissipated, route com-

ponent wiring back through the bottom front panel wire-

way.

• Reinstall the tubing grommets and close the top and bot-

tom front panels.

• Re-install the control panel to the top and bottom front

panel using mounting location holes and factory supplied

screws.

• Reconnect Control Panel wiring to component wiring.

• After the work is finished, make sure to check that there is

no gas leak.

• After checking for gas leaks, be sure to insulate the piping

connections as shown in Figure 10.

Completely insulate gas refrigerant piping in order to prevent con-

densation and possible water damage. Failing to insulate the pipes

may cause leaking or burns. Be sure to use insulation which can

withstand temperatures of 250° F (120° C) or more. Reinforce

the insulation on the refrigerant piping acording to the installa-

tion environment. If environmental conditions reach 86°and 80%

RH, condensate may form on the surface of the insulation. To

prevent condensate leakage, reinforce the refrigerant piping in-

sulation according to the installation environment.

Do not leave a gap

Gas piping

Piping heat insulation

materia

l

Cased

Coil

Figure 10

• Do not allow component wiring to become pinched. Failure

to do so may le ad to u ni t fa ilure.

• Be sure to insulate gas piping all the way (required insulation),

to piping connection inside the unit. Any exposed piping may

cause condensation or burns if touched.

Loading...

Loading...