Troubleshooting for Outdoor Unit SiBE121123_A

185 Service Diagnosis

7.4 Unspecified Voltage (between Indoor Unit and Outdoor

Unit) / Anti-icing Control in Other Room

Error Code

UA, UH

Method of Error

Detection

A wrong connection is detected by checking the combination of indoor and outdoor units on the

microcomputer.

Error Decision

Conditions

Anti-icing control in other room

Unspecified internal and/or external voltages

Mismatching of indoor and outdoor units

Supposed

Causes

Anti-icing control in other room

Wrong models interconnected

Wrong indoor unit PCB or outdoor unit PCB mounted

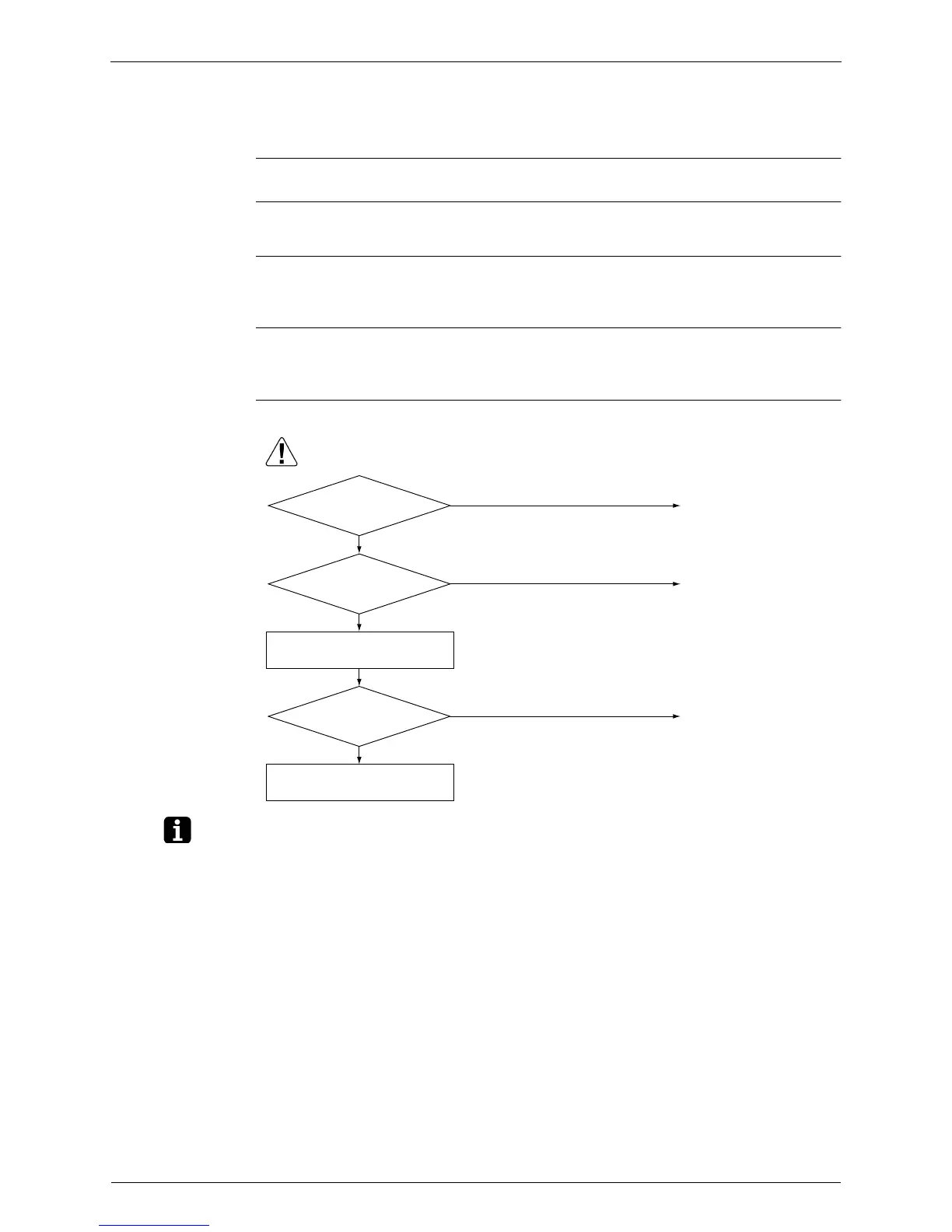

Troubleshooting

Note: Refer to “Anti-icing control for indoor unit” on page 186 for detail.

(R16018)

Caution

NO

YES

NO

YES

NO

YES

Check the model combination.

Check the combination of all the

models being connected.

The anti-icing function is

activated in other rooms.

Refer to A5.

Correct the supply voltage.

Match the compatible models.

Be sure to turn off the power switch before connecting or disconnecting

connectors, or parts may be damaged.

Error displayed while

operating?

Supply voltage as

specified?

Matched compatibly?