InsTallaTIon

www.DaikinApplied.com 21 IOM 1266-2 • MAGNITUDE

®

MODEL WME CHILLERS

Field Insulation

If the optional factory installation of thermal insulation is not

ordered, insulation should be eld installed to reduce heat

loss and prevent condensation from forming. Insulation should

cover:

• the evaporator barrel, tube sheet, and waterboxes.

• the suction line from the top of the evaporator to the

compressor inlet ange.

• the compressor support brackets welded to the

evaporator.

• the liquid line from the expansion valve to the evaporator

inlet, including the expansion valve.

• the part load balance valve to the evaporator.

Approximate total square footage of insulation surface required

for individual packaged chillers is tabulated by evaporator code

and can be found in Table 8.

Table 8: Insulation Area Required for WME Models

Evaporator Code

Insulation Area

sq. ft. (m

2

)

E3012 115 (10.6)

E3612 129 (11.9)

E4216 263 (24.4)

E4816 302 (28.1)

Field Power Wiring

The standard power wiring connection to Magnitude

®

chillers

is multi-point for dual compressor WME models. Power conduit

entry will be at the top of the unit power panel; see Figure 21

for general reference as power entry cover plate location will

vary by unit conguration. Copper or aluminum wiring may

be used for power wiring. Refer to the unit nameplate and the

Daikin Tools selection report for the correct electrical ratings.

DANGER

Qualied and licensed electricians must perform wiring. An

electrical shock hazard exists that can cause severe injury

or death.

Figure 21: Unit Power Connection Point

Factory-mounted and wired line reactors are standard. The

eld control wiring required varies depending on unit model.

See “Figure 24: WME Field Wiring Schematic” on page 23

for wiring information. These wiring diagrams are also provided

with the chiller.

NOTE: Wiring, fuse, and wire size must be in accordance

with the National Electrical Code

®

(NEC). The voltage

to these units must be within ±10% of nameplate

voltage (415V units must have voltage within -13%

and +6% of nameplate voltage) and the voltage

unbalance between phases must not exceed 2%.

Since a 2% voltage unbalance will cause a current

unbalance of 6 to 10 times the voltage unbalance per

the current version of the NEMA MG-1 Standard, it is

most important that the unbalance between phases

be kept at a minimum.

CAUTION

Do not use power factor correction capacitors with WME

chillers. Doing so can cause harmful electrical resonance in

the system. Correction capacitors are not necessary since

VFDs inherently maintain high power factors.

See “Use with On-Site Generators” on page 51 for additional

information on Generator Sizing and Transferring Power.

Chiller Control Power

In all cases of power operation except when with

RapidRestore

®

, the chiller control power must remain as

factory-wired from a unit-mounted power supply.

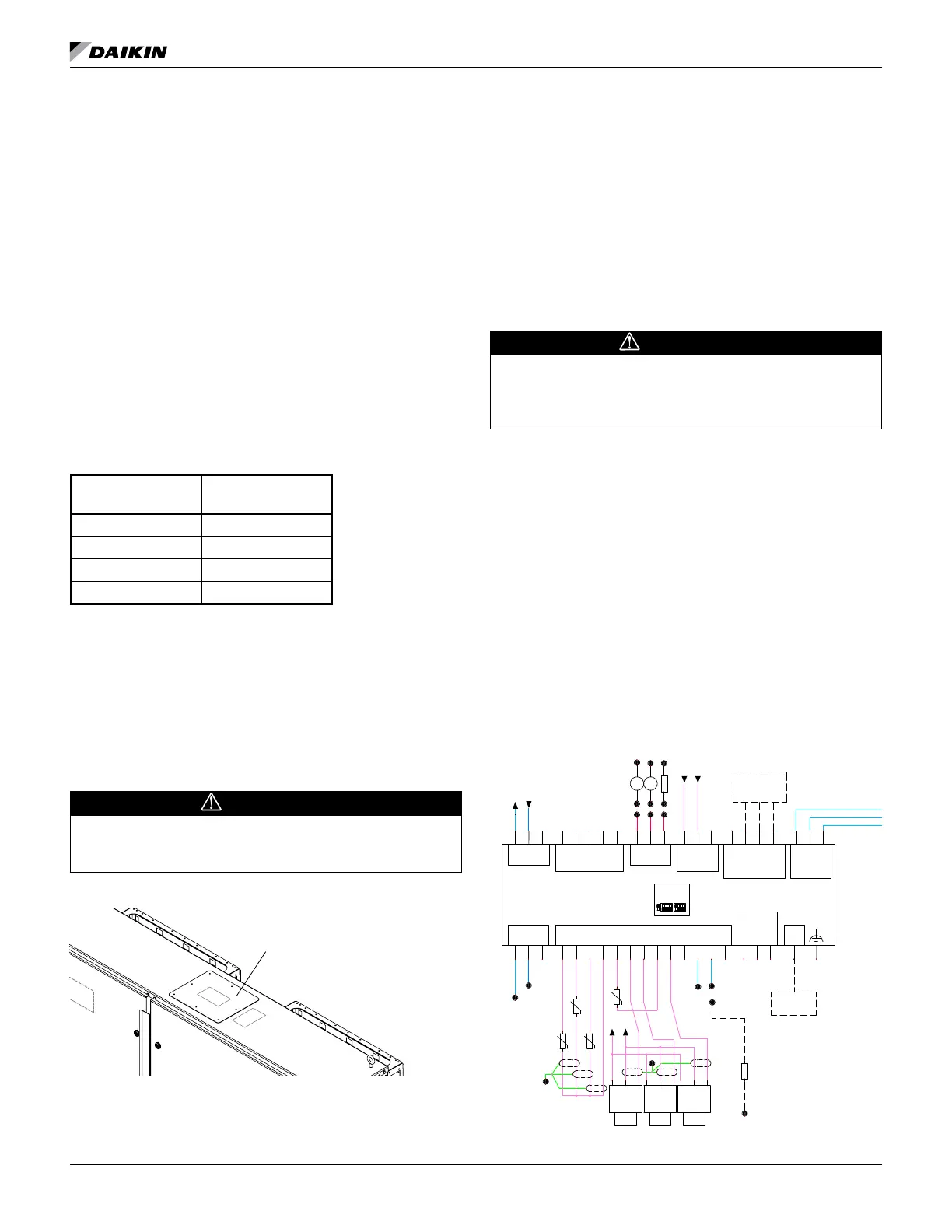

BAS Connection

If BAS module is needed for BACnet

®

or Modbus, the UE1

module will be replaced with the BUE1 module shown in Figure

22 for wiring. When Lon protocol is used the UE1 module

remains and a Lon card is connected to the Unit controller in

the BMS CARD port.

Figure 22: BAS Module Wiring Schematic

Power Entry Cover Plate -

Remove to cut hole in

cover plate for conduit

and then replace.

REVISIONPART NUMBER

1

2

3

336078102 0A

WME-C UNIT BOX SCH

WHT(2)

RED(2)

GRN(2)

BLK(2)

S+

S-

REF

OPEN

B

W

G

R

24V+

24V-

ON

1234 5678

EXVDRV

111111

L2

11

L2

20

ACT2

ACT1

PC RESET

22

BA

35

LONMARK WIRING

GND

BLK

33

23

BLK

BLU

BRN

WHT

+24VAC/DC

24N

CEFS

BLU

33

23

23

BLK

BRN

WHT

+24VAC/DC

24N

EEFS

23

21

SW1 (UNIT SWITCH)

3

4

WHT

WHT

WHT

SWITCH

31

22

31

REMOTE

PWR

INPUT

TOWER STAGE #3

6

TOWER STAGE #2

CONDENSOR PUMP #2

54

TOWER STAGE #1

TS1

CP2

654

EVAP PUMP #1

EVAP PUMP #2

321

L1

L1

321

CB1

6A

EP2

EP1

30

29

BLK

32

20

35

35

0-10V

COOLING TOWER VFD

0-10V

COOLING TOWER BYPASS VALVE

3029

RED

28

PE

7

7

TS3

TS2

36

36

13

121212

CONDENSOR PUMP #1

CP1

-

+

34

22

E-PORT1

CMPR BOX #1

OR MODBUS

FOR BACNET-MSTP

FIELD WIRING

ADAPTER

SEE DWG 336078103

E-PORT2

CMPR BOX #2

BACNET-IP

FIELD WIRING

34

(SCALE: 0-125% RLA)

0-10V

UNIT MOTOR CURRENT OUTPUT

VDC OR VAC

NC

NO

ALARM NO/NC

AR4

24/120V

RED(3)

BLK(3)

10

8

9

SENSOR

SENSOR

10

8

9

EXV BOARD CAL

AR3

24

WHT

WHT

BLK

RED

PWR

GND

SIG

LLP

PE

PWR

GND

SIG

EVPP

PWR

GND

SIG

CNDP

BLK(3)

RED

RED

RED

32

21

PE

Address = 1

G

G0

Vbat

U2

U1

U3

GND

U4

U5

U6

GND

U7

U8

U9

U10

GND

NO1

C1/2

NO2

NO3

C3/4/5

NO4

C3/4/5

NO5

NO6

NC6

C6

J1

J2

J10

J11

J12

EHUB

J9

+5Vref

GND

+Vdc

MODBUS

ON

1

234 1234

UE1

Tx-/Rx-

Tx+/Rx+

GND

TxL/RxL

TxH/RxH

GND

J5 CAN

+Vtwrm

Tx-/Rx-

Tx+/Rx+

GND

J3 DISP

J4 FBus

(OPTION)

BUE1

25

25

S1

HMI

PC1

24/120VAC

Customer

CUSTOMER SUPPLIED POWER

J5

C1

J3

T

U3

GND

+VD

C

J2

J12

NO1

U4

GND

U5

GND

Y1

VG0

VG

Y2

Y3

Y4

BMS CARDFIELD BUS CARD

ID1

J4

NO2

C1

C4

C4

NO4

NO5

NO6

NO3

J13

C7

C7

NO7

NO8

NC8

J25 BMS2

+

GND

-

C8

J14

-

GND

+

J26 FBus2

ID2

ID3

ID4

ID5

ID6

ID7

ID8

IDC1

J15

UC1

01-10

01-4

01-10

01-4

01-2

01-2

01-9

01-5

24-18

24N-8

USB

24N-7

24-8

120N-1

GRN

WHT

RED

BLK

24-18

24-23

24N-3

SW-2

UC1:ID7

-

+

-

+

U

C

1

:

I

D

7

U

C

1

:

I

D

6

2

4

-

9

SW-1

1

2

0

-

9

120-10

1

2

0

-

8

1

2

0

-

7

120-6

1

2

0

-

1

1

2

0

-

5

1

2

0

-

4

1

2

0

-

3

1

2

0

-

2

2

4

-

7

2

4

-

8

2

4

N

-

2

2

4

-

5

2

4

-

4

1

2

0

-

1

1

2

4

N

-

1

0

2

4

-

1

9

2

4

N

-

9

2

4

N

-

1

1

ETR3

V

G

A

ETR4

24-15

24-16

24-17

1

2

0

-

1

3

1

2

0

-

1

4

1

2

0

-

1

2

G

N

D

+

5

V

2

4

N

-

7

2

4

-

1

1

2

4

-

1

4

2

4

-

1

3

+

5

V

G

N

D

2

4

-

1

2

2

4

N

-

4

E

T

R

2

U

C

1

:

I

D

6

S

W

-

1

01-10

01-5

2

4

-

1

1

+

+

2

4

-

6

2

4

-

2

0

UP TO 4 ACTUATORS

SEE PAGE 2 FOR

SECT 2

RM/POWER WIRING

11 12 13

UTB1 TERMINAL BLOCK JUMPERS

NEUTRAL BLOCK

98

1065 732 41

EEWT

ELWT

CEWT

CLWT

LLT

01-12

01-12

01-5

01-2

01-3

Loading...

Loading...