IOM 1266-2 • MAGNITUDE

®

MODEL WME CHILLERS 56 www.DaikinApplied.com

sTarTup and MaInTenanCe

Maintenance Schedule

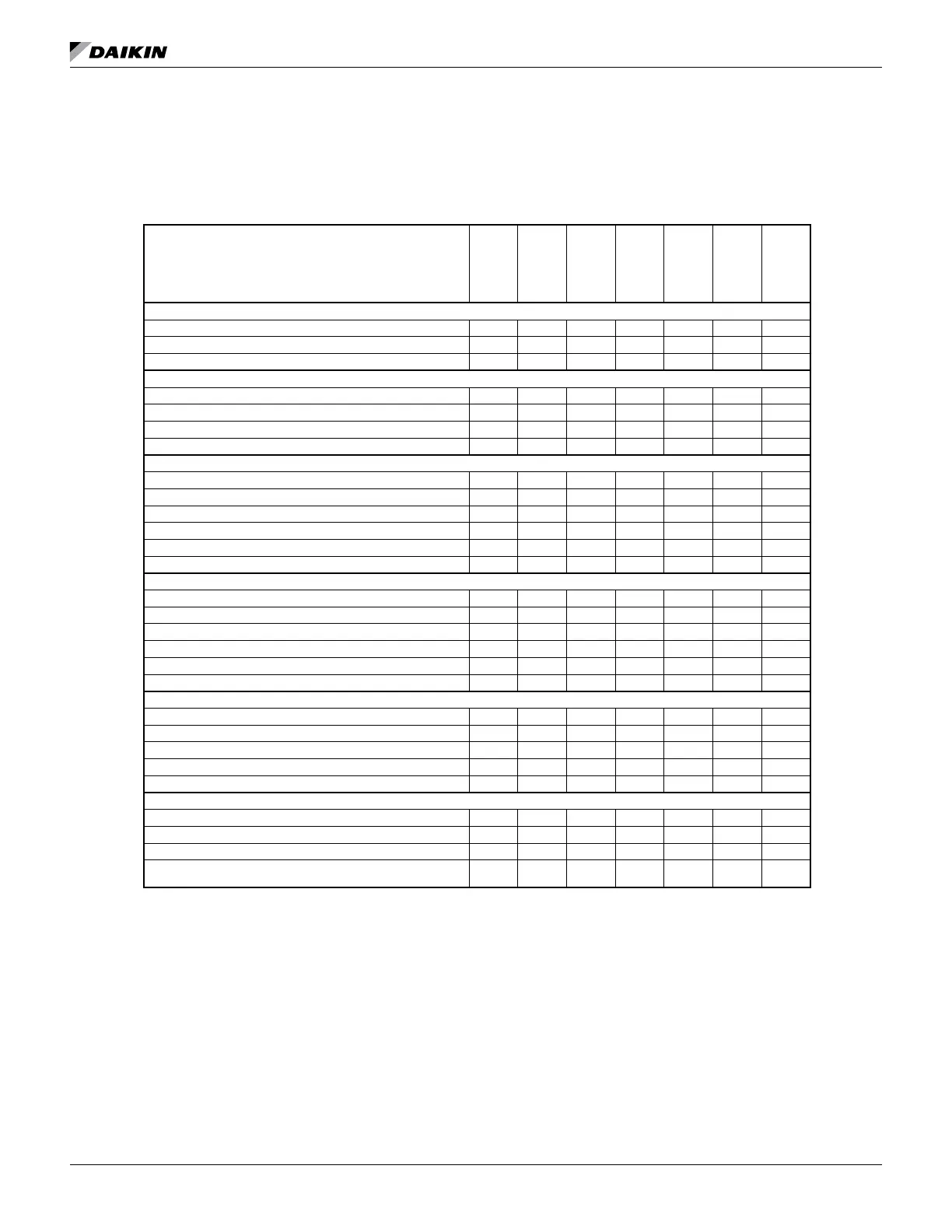

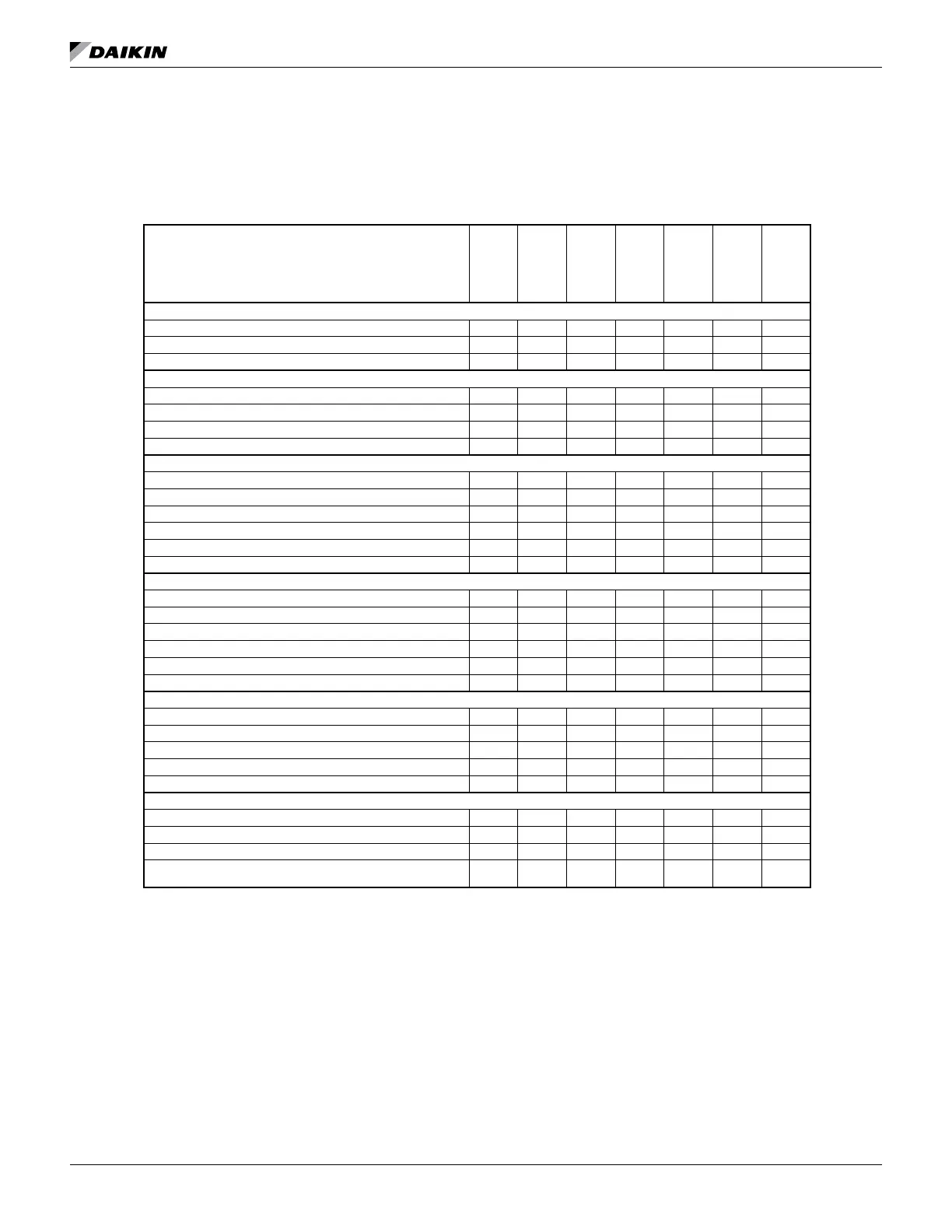

Table 34 provides an overview of recommended maintenance procedures along with how frequently these procedures should be

performed.

Table 34: Recommended Maintenance Schedule

Monthly

Quarterly

Semi-

Annually

Annually

As Required

By

Performance

During

Seasonal

Shutdown

During

Seasonal

Startup

I. Compressor

A. Analyze Compressor Fault Log X

B. Check IGV operation X

C. Check and tighten compressor electrical connections X

II. MicroTech

®

Controls

A. Check for proper settings X

B. Verify transducers and sensors for accuracy X

C. Retrieve and archive HMI Trend Logs O

D. Perform MicroTech

®

check, log, and last fault analysis X

III. Condenser

A. Conrm correct water ow and pressure drop O X

B. Conrm appropriate water treatment O

C. Clean and Leak Test condenser tubes X X X

D. Eddy Current Test - tube wall thickness X

E. Seasonal Protection X

F. Clean Flow Sensor X X

IV. Evaporator

A. Conrm correct water ow and pressure drop O X

B. Conrm appropriate water treatment O

C. Clean and Leak Test evaporator tubes X

D. Eddy Current Test - tube wall thickness X

E. Seasonal Protection X

F. Clean Flow Sensor X

V. Chiller Unit

A. Run Test/Performance Evaluation X

B. Leak Test entire unit X X X

C. General Appearance:

1. Paint/Corrosion X

2. Insulation X

VI. Electrical

A. Check and record line voltage X

B. Inspect power components for signs of overheating X

C. Check and tighten unit electrical components X X

D. Check all panels for cleanliness - remove dust and debris

from electrical boards and connections

X

Key: O = Performed by owner personnel X = Performed by qualied service personnel

Harmonic Filter Evaluation

If the optional harmonic lter is provided with the chiller,

measuring the current in each of the three phases of the

capacitor circuit may help determine the condition of the

capacitors. If the input phase currents are within a 5% match to

each other and approximately 30% of lter current rating, the

capacitors can be assumed to be in good working condition.

Phase currents that are imbalanced, may indicate a capacitor

failure. Testing should be done whenever the unit appears to

be operating in an abnormal state.

When the unit is off, the harmonic lter may be checked for

resistance levels. Using a multi-meter (set to read 100K ohms)

to check the phase-to-phase isolation, the reading should

be about 40K (total equivalent bleeder resistance value) and

should be the same for each phase. Open circuit or very

low readings indicate an issue. Also check phase-to-chassis

resistance as low readings indicate a ground fault problem.

Loading...

Loading...