Points of Analysis Si30-408

180 Service Checker Type3 Application Edition

5.3 Effective Use of Checker

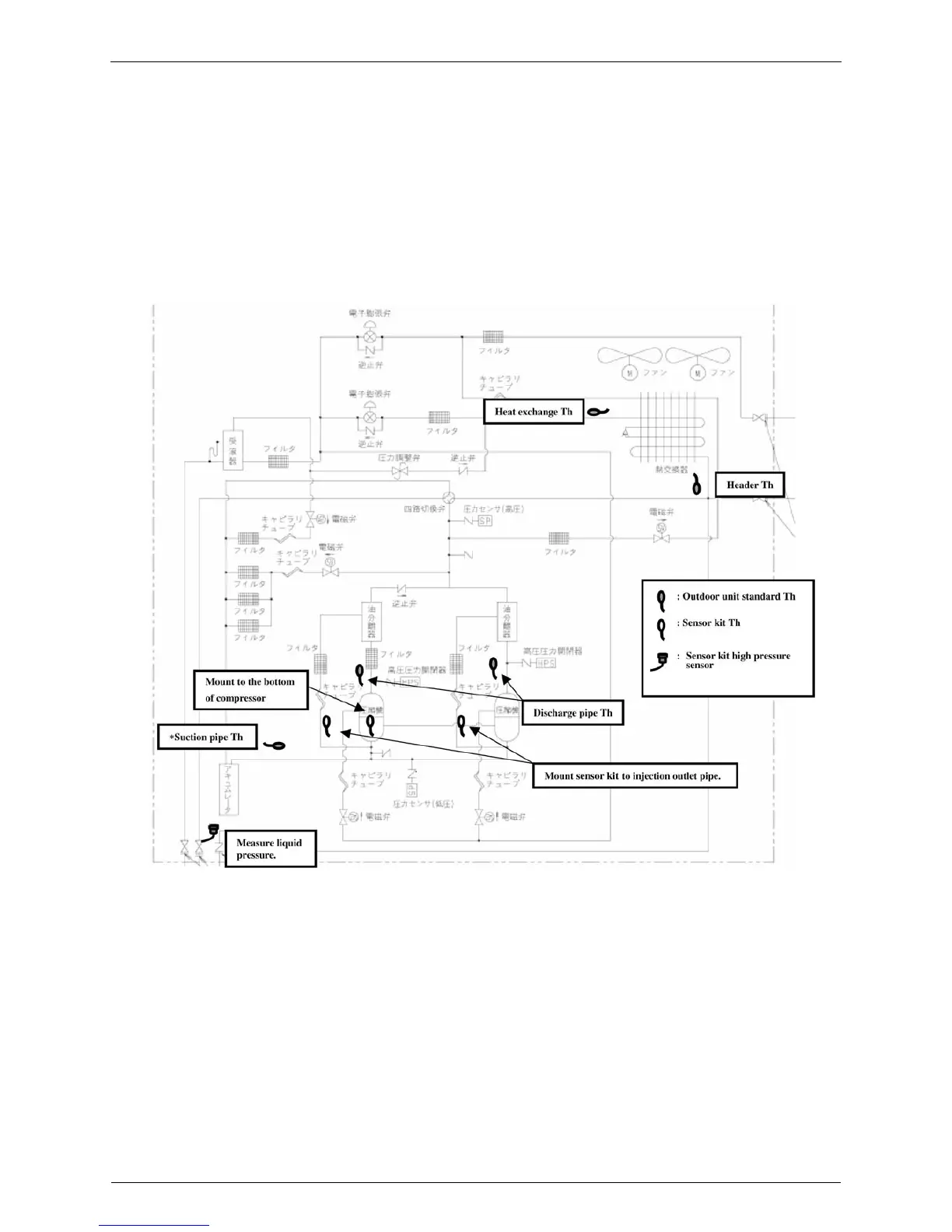

Probe causes of wet operation using the Checker in combination with sensor kits.

Most of current malfunctions on compressors result from seizing of or damage to the

compressors due to the dilution of lubricant (refrigerant oil) caused while the compressors are in

wet operation.

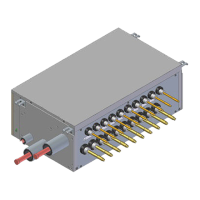

In order to verify the wet operation using the Checker Type3, using DIII-NET and sensor input in

combination enables the collection of effective data.

(If the Checker is connected to PC board, no sensor kits can be used in combination.)

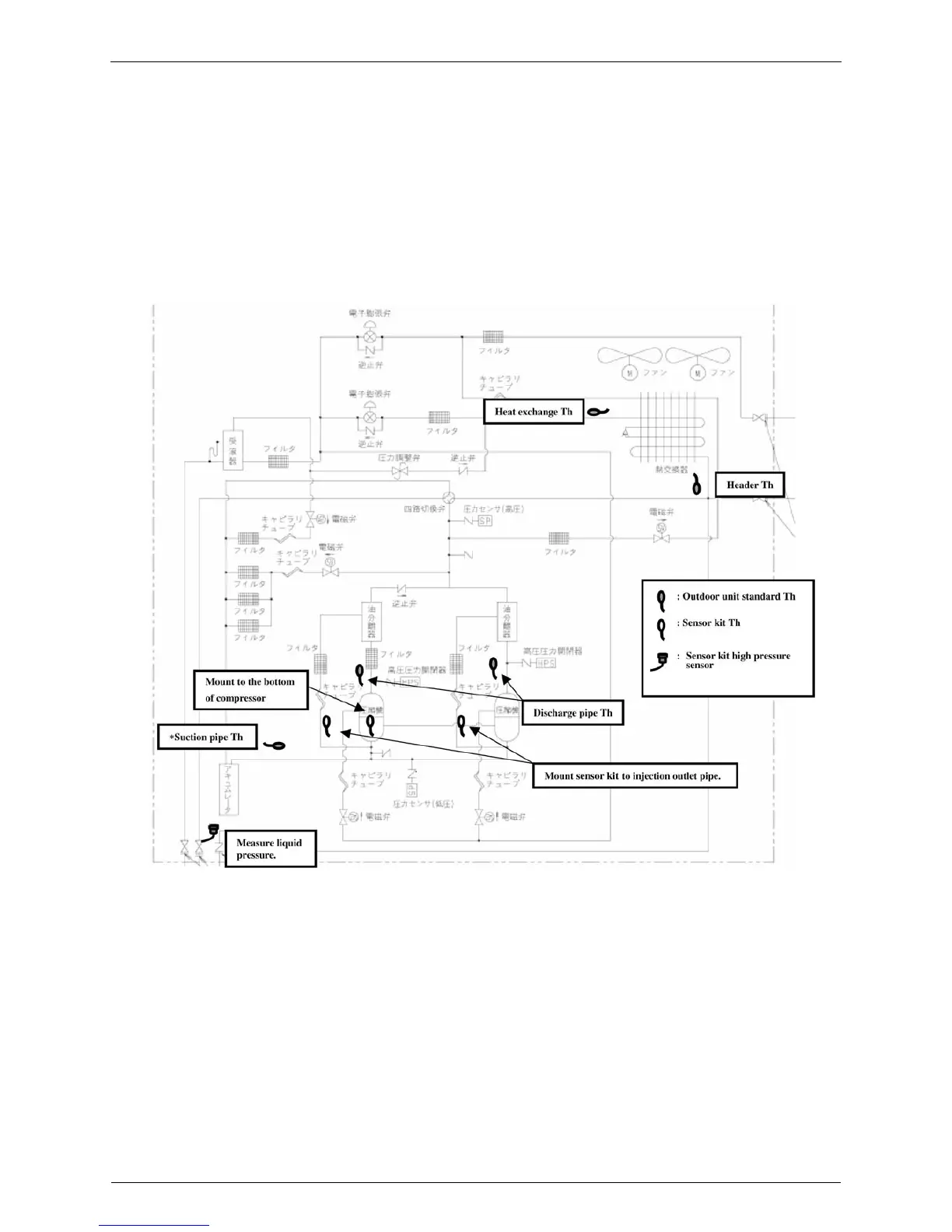

(Example of connection) For RSXYP16KJY1 (Information on slave units is omitted.)

Through the ON/OFF operation of Injection solenoid valve and the temperature of outlet

pipe, determine whether or not oil leaks inside the solenoid valve.

Measure the melting refrigerant into oil according to the temperature at the bottom of

compressor and also wet operation according to compressor operating temperature.

Since the position of the suction pipe Th varies with models, mount the sensor kit Th in a

place where the suction pipe is connected at all times.

Loading...

Loading...