46 Capacity controller RS8HE202 © Danfoss 2017-07 AK-PC 781A

Wiring

Decide during planning which function is to be connected and

where this will be.

1. Connect inputs and outputs

Here are the tables for the example:

Mounting and wiring - continued

The function of the switch functions can be seen in the last column.

There are pressure transmitters AKS 32R and AKS 2050 available for

several pressure ranges.

Here there are two different ones. One up to 59 bar and two up to 159

bar.

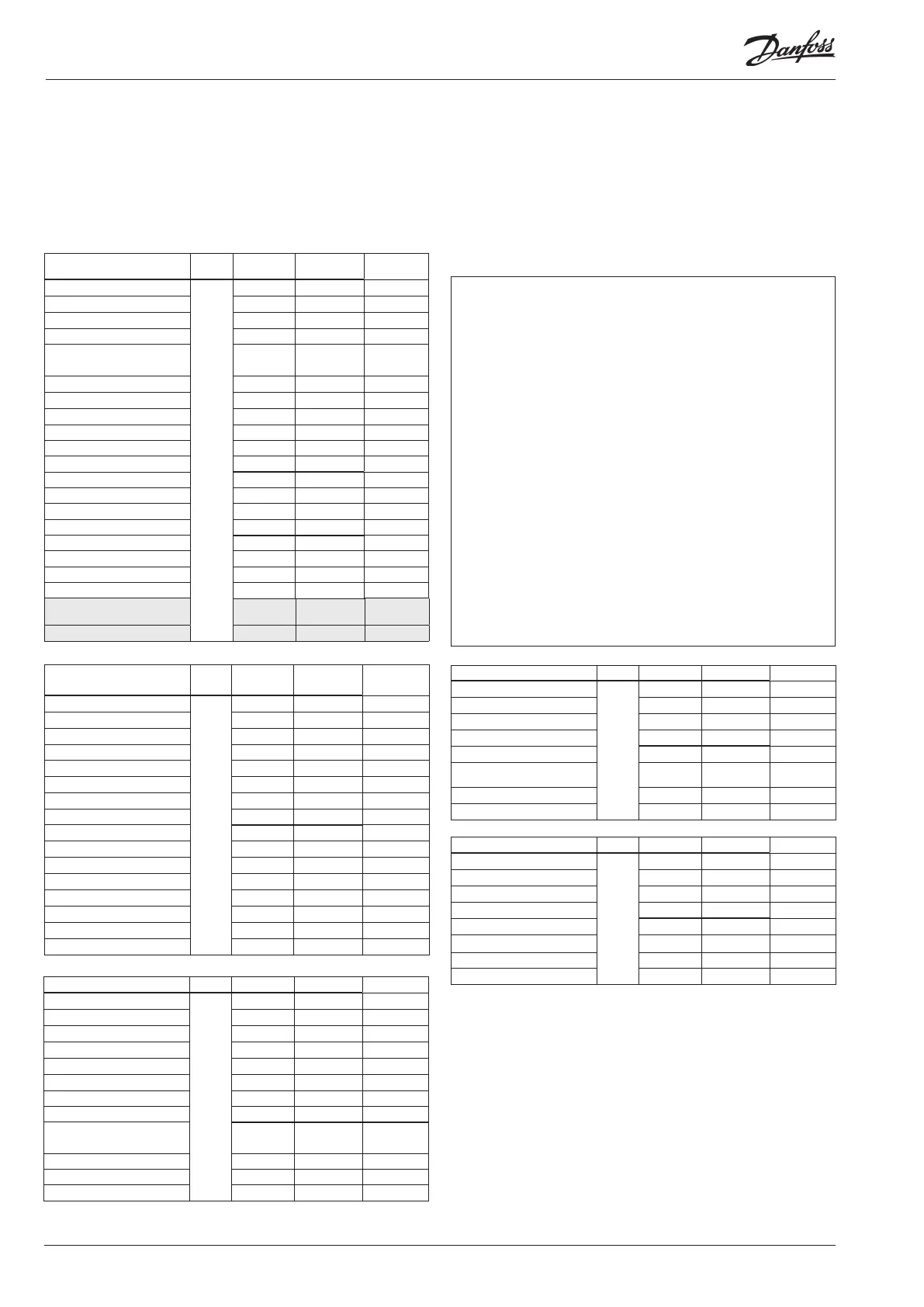

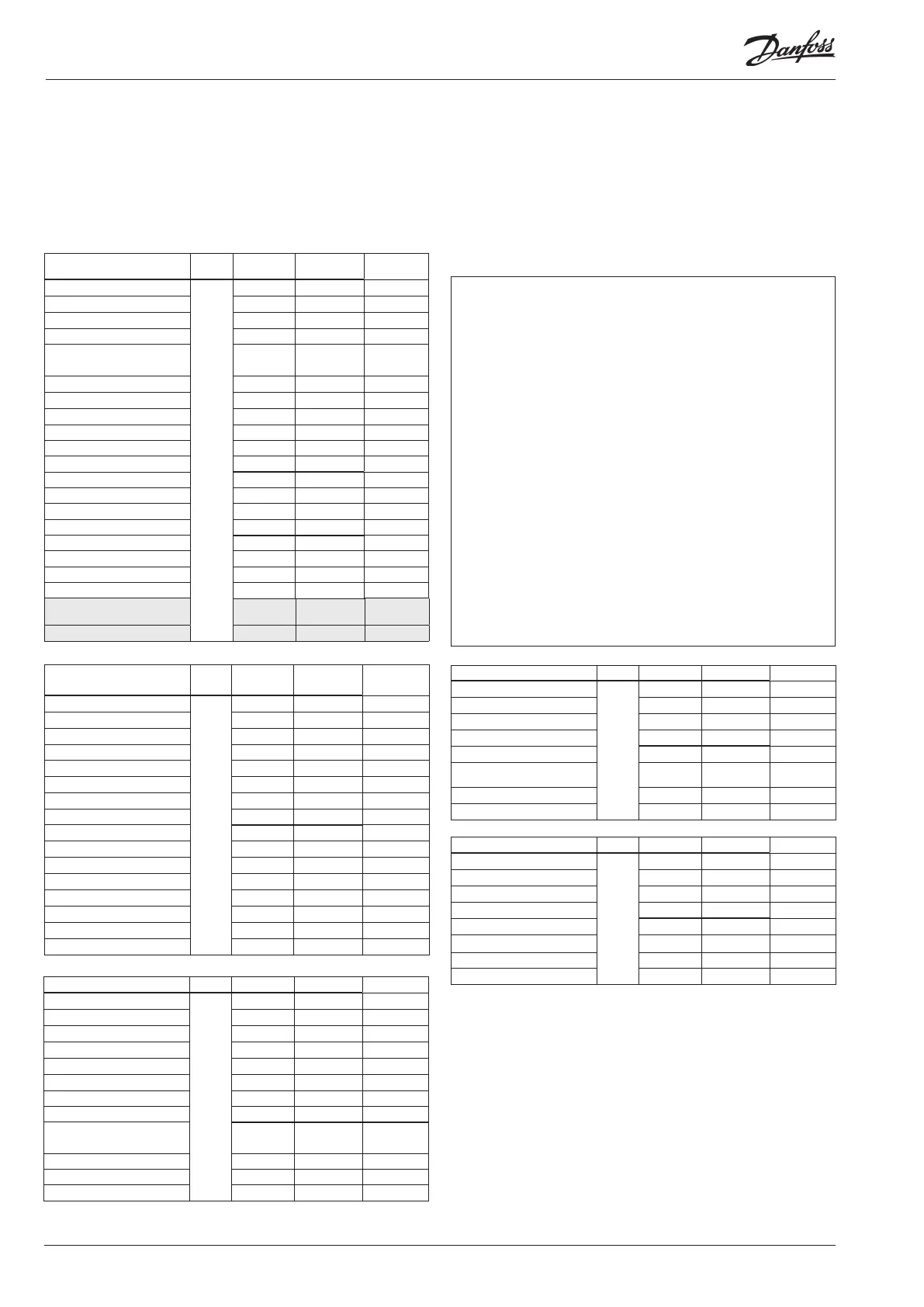

Signal Module Point

Terminal

Signal type /

Active at

Level switch, oil, receiver High

2

1 (AI 1) 1 - 2 closed

Level switch, oil, receiver Low 2 (AI 2) 3 - 4 closed

Level switch, oil, Separator 3 (AI 3) 5 - 6 closed

Level switch, CO2 receiver 4 (AI 4) 7 - 8 Open

Pulse reset of stopped compressor 5 (AI 5) 13 - 14 Pulse

6 (AI 6) 15 - 16

Refrigerant, receiver, Prec CO2 7 (AI 7) 17 - 18 AKS 2050-159

Oil receiver, Prec Oil 8 (AI 8) 19 - 20 AKS 2050-159

Compressor 1 9 (DO 1) 25 - 26 - 27 ON

Compressor 2 10 (DO 2) 28 - 29 - 30 ON

Compressor 3 11 (DO 3) 31 - 32 - 33 ON

Compressor 4 12 (DO 4) 34 - 35 - 36 ON

Start /stop of VLT to fans 13 (DO 5) 37 - 38 - 39 ON

3-way valve, tap water, V3tw 14 (DO6) 40 - 41 - 42 ON

3-way valve, heat circuit, V3hr 15 (DO7) 43 - 44 - 45 ON

3-way valve, gas cooler, V3gc 16 (DO8) 46 - 47 - 48 ON

Signal Module Point

Terminal

Signal type /

Active at

Discharge gas temperature - Sd

1

1 (AI 1) 1 - 2 Pt 1000

Suction gas temperature - Ss 2 (AI 2) 3 - 4 Pt 1000

Outdoor temperature - Sc3 3 (AI 3) 5 - 6 Pt 1000

External compressor stop 4 (AI 4) 7 - 8 closed

Thermostat sensor in plant room

- Saux1

5 (AI 5) 9 - 10 Pt 1000

Suction pressure - P0 6 (AI 6) 11 - 12 AKS 2050-59

Condenser pressure - Pc 7 (AI 7) 13 - 14 AKS 2050-159

Level switch, oil, comp. 1 8 (AI 8) 19 - 20 closed

Level switch, oil, comp..2 9 (AI 9) 21 - 22 closed

Level switch, oil, comp..3 10 (AI 10) 23 - 24 closed

Level switch, oil, comp..4 11 (AI 11) 25 - 26 closed

Solenoid valve, oil, Comp. 1 12 (DO 1) 31 - 32 ON

Solenoid valve, oil, Comp. 2 13 (DO 2) 33 - 34 ON

Solenoid valve, oil, Comp. 3 14 (DO 3) 35 - 36 ON

Solenoid valve, oil, Comp. 4 15 (DO 4) 37 - 38 ON

Solenoid valve , oil, Separator 16 (DO 5) 39 - 40 - 41 ON

Circulation pump tw 17 (DO6) 42 - 43 - 44 ON

Circulation pump hr 18 (DO7) 45 - 46 - 47 ON

Room fan 19 (DO8) 48 - 49 - 50 ON

Voltage signal to high pressure

valve, ICMTS

24 - 0-10 V

25 -

Signal Module Point Terminal Active at

Compressor 1 Gen. safety

4

1 (DI 1) 1 - 2 Open

Compressor 2 Gen. safety 2 (DI 2) 3 - 4 Open

Compressor 3 Gen. safety 3 (DI 3) 5 - 6 Open

Compressor 4 Gen. safety 4 (DI 4) 7 - 8 Open

Start/stop heat recovery hr 5 (DI 5) 9 - 10 closed

All comp. common safety 6 (DI 6) 11 - 12 Open

Flow switch FStw 7 (DI 7) 13 - 14 Open

Flow switch FShr 8 (DI 8) 15 - 16 Open

Signal Module Point Terminal Signal type

Temp. gas cooler outlet Sgc

5

1 (AI 1) 1 - 2 Pt 1000

Temp. by-passed gas Shp 2 (AI 2) 3 - 4 Pt 1000

Start/stop heat recovery tw 3 (AI 3) 5 - 6 closed

Gas cooler pressure Pgc 4 (AI 4) 7 - 8 AKS 2050-159

Speed control, compressor 5 (AO 1) 9 - 10 0 - 10 V

Speed control, gas cooler fans 6 (AO 2) 11 - 12 0 - 10 V

Speed control, pump - tw 7 (AO 3) 13 - 14 0 - 10 V

Speed control, pump - hr 8 (AO 4) 15 - 16 0 - 10 V

Signal Module Point/Step Terminal Signal type

Tap water temperature - Stw2

3

1 (AI 1) 1 - 2 Pt 1000

Tap water temperature - Stw3 2 (AI 2) 3 - 4 Pt 1000

Tap water temperature - Stw4 3 (AI 3) 5 - 6 Pt 1000

Tap water temperature - Stw8 4 (AI 4) 7 - 8 Pt 1000

Heat reclaim temperature Shr2 5 (AI 5) 9 - 10 Pt 1000

Heat reclaim temperature Shr3 6 (AI 6) 11 - 12 Pt 1000

Heat reclaim temperature Shr4 7 (AI 7) 13 - 14 Pt 1000

Heat reclaim temperature Shr8 8 (AI 8) 15 - 16 Pt 1000

Stepper signal to by-pass valve,

CCMT

9 (step 1)

25 - 26 - 27 - 28

CCMT (ETS)

10 (step 2) 29 - 30 - 31 - 32

11 (step 3) 33 - 34 - 35 - 36

12 (step 4) 37 - 38 - 39 - 40

Remember the isolation amplifier

If signals are received from different controls, e.g. heat re-

covery for one of the inputs, a galvanically insulated module

should be inserted.

Loading...

Loading...