1.

2.

2.1.

2.2.

2.3.

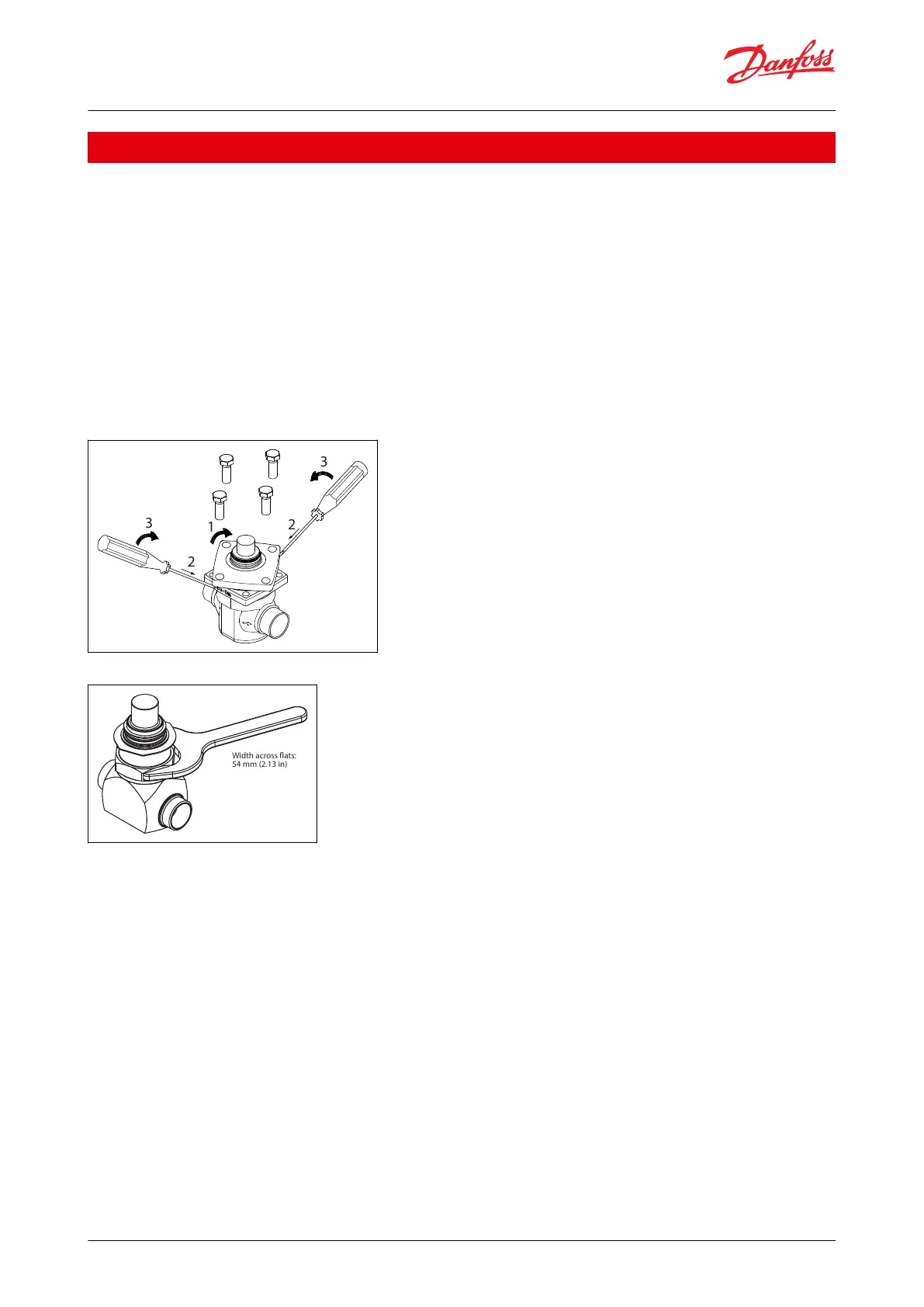

Figure 1: Removing the bonnet/function module from the body of the ICM 25 to 65 valves

Installation

All ICM and ICMTS valves and ICAD motor actuators must be installed in horizontal pipelines with the motor

actuator in an upright position (+/- 45° for ICMTS 50/80)

Preparation of Valve Body ICM 20 and ICMTS 20 valves: both the integrated bonnet/function module and the

separate valve seat must be removed from the valve body prior to welding. To remove the 20-A33 or ICM20-A

valve seat use a 13mm socket wrench and to remove the 20-B66, ICM 20-B or 20-C valve seat, use a 12 mm hex

key

ICM 25 to 65 and ICMTS 50/80 valves, the integrated bonnet and function module should be removed as

shown in the Figure 1

ICMTS 20 valve, the function modulet should be removed as shown in the Figure 1

ICM 100 to 150 valves, the function module and bonnet are separate pieces and do not need to be

removed prior to welding. However, some form of arc welding should be used to weld the valve into the

piping and care should be taken to protect the valve stem from becoming contaminated

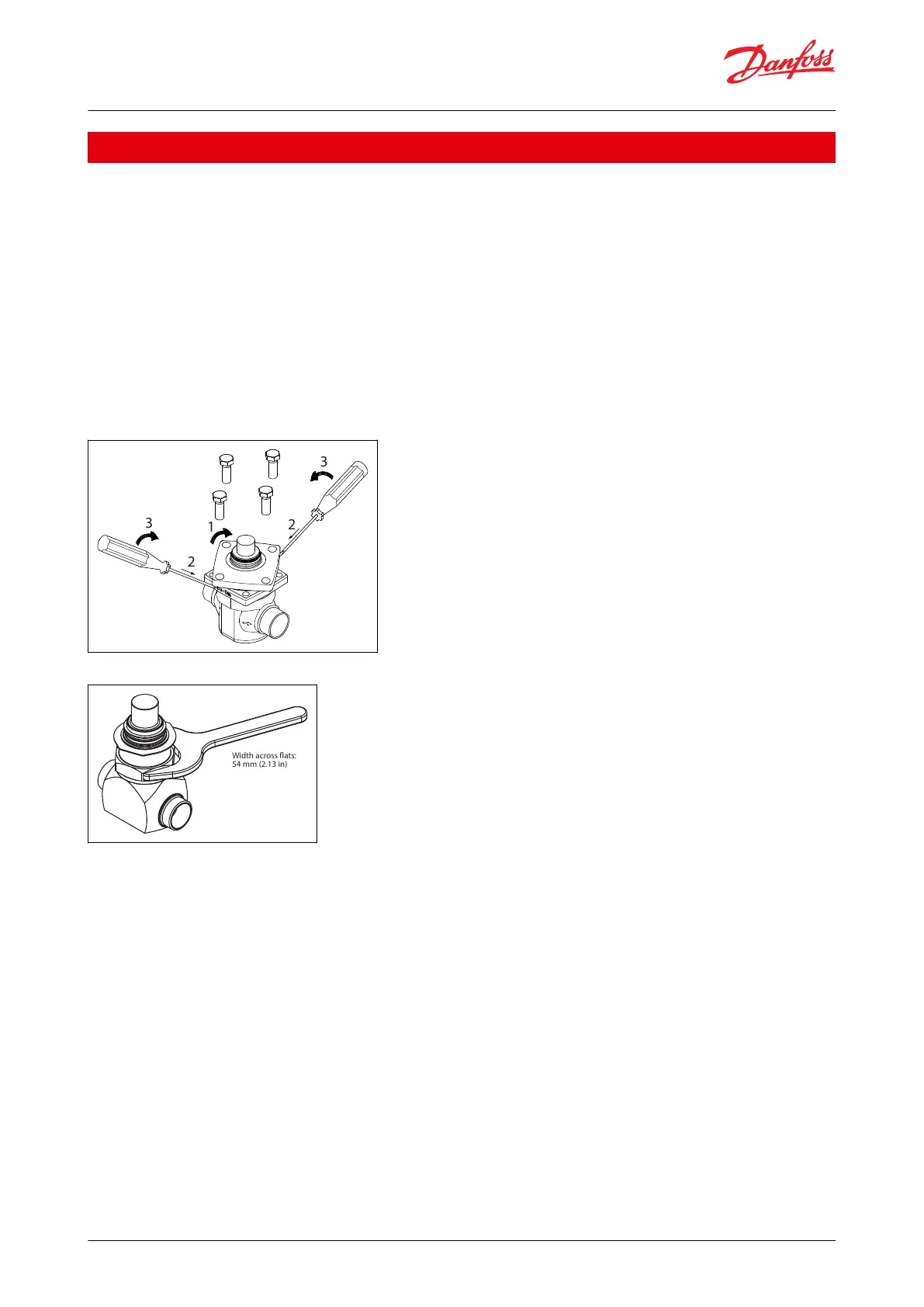

Figure 2: Removing the bonnet/function module from the body of the ICMTS 20 valves

54 mm (2.13 in)

Width across flats:

© Danfoss | Climate Solutions | 2024.01 BC465027827472en-000102 | 5

ICM and ICMTS Motorized Valves with ICAD Actuators

Loading...

Loading...