MCD 200 Design Guide

16 MG.17.C3.02 – VLT is a registered Danfoss trademark

MCD 202

3 Wire Control

380-440 VAC (CV3)

A3

A1

A2

N1

N2

START

STOP

*

A3

A1

A2

N1

N2

START

STOP

*

(+)

(-)

110-240 VAC (CV3)

OR

24 VAC/VDC (CV1)

177HA210.11

* Also resets the MCD 202

■ Functionality

User Adjustments

Trip

Run

Aux Relay

Motor Trip

Class

Phase

Rotation

Excess

Start Time

OFF

2

4

6

8

10

12

14

16

20

ANY

FWD

ANY

FWD

OFF

2

4

6

8

10

12

14

16

20

No

Soft Stop

2s

4s

6s

8s

10s

12s

14s

16s

20s

100%

70% 80%

60% 90%

50%

350%

450%

400%300%

250%

OFF

2s

5s

15s

15

2s

5s

15s

5s

2s

(% MCD202 FLC)(%FLC / Ramp Time)

(% Motor FLC )

Motor FLC

I

Current Ramp

I

Current Limit

Soft Stop

U

I

M

2

0

0

%

F

L

C

2

5

0

%

F

L

C

1

5

0

%

F

L

C

177HA255.11

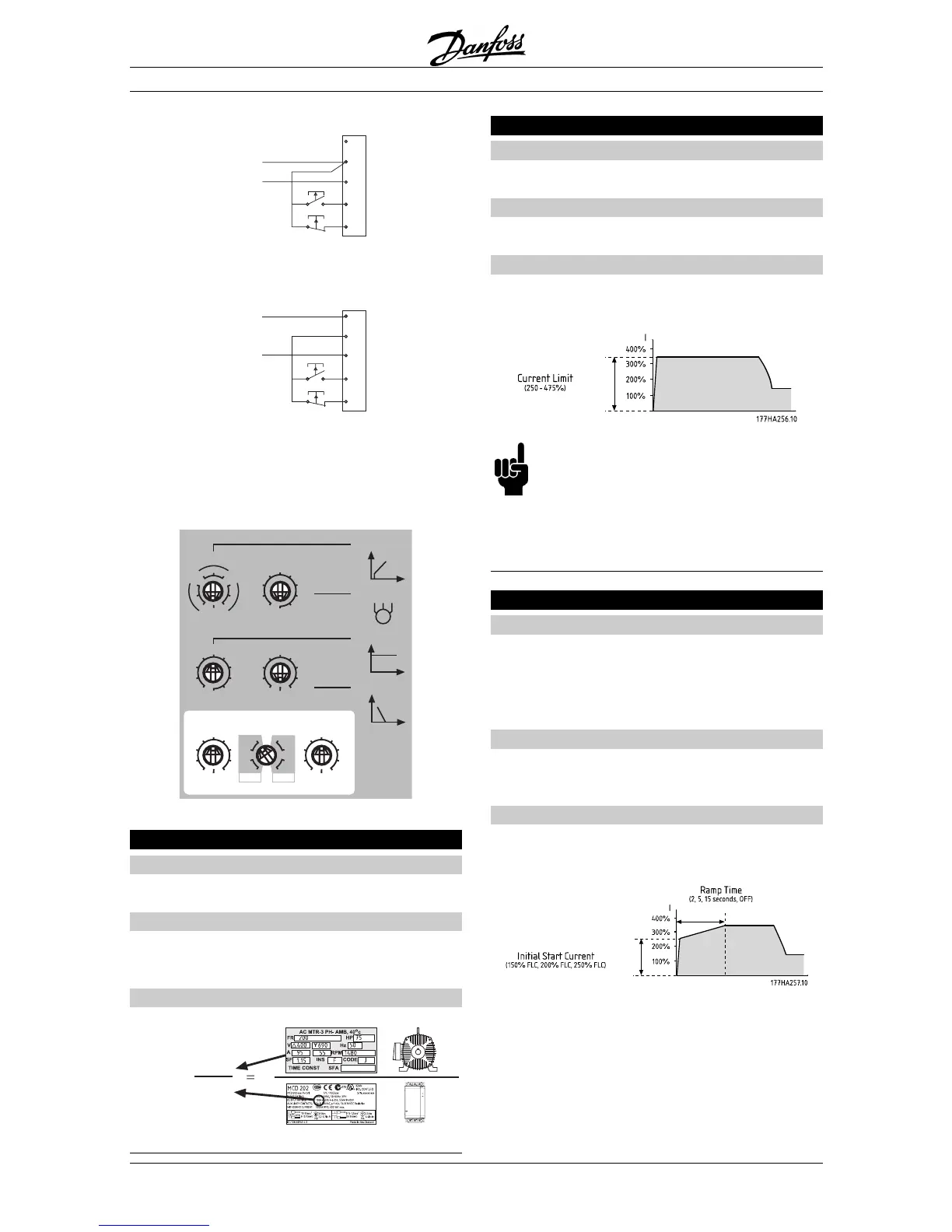

1 Motor FLC

Value:

50% - 100% MCD 202 FLC

✭ 100%

Function:

Calibrates the MCD 202 for the Full Load Current of

the motor.

Description of choice:

95%

=

100 A

95 A

177HA233.12

2 Current Limit

Value:

250% - 475% Motor FLC

✭ 350%

Function:

Sets the desired starting current limit.

Description of choice:

The current limit should be set so that the motor

accelerates easily to full speed.

NB!:

Start current must be great enough to allow

the motor to produce sufficient torque to

accelerate the connected load. The minimum current

required to do this is dependent on motor design and

load torque requirements.

3 Current Ramp

Value:

150% Motor FLC (2, 5 or 15 seconds)

✭ Off

200% Motor FLC (2, 5 or 15 seconds)

250% Motor FLC (2, 5 or 15 seconds)

Off

Function:

Sets the initial starting current and ramp time for the

Current Ramp start mode.

Description of choice:

The Current Ramp start mode modifies the Current

Limit start mode by adding an extended ramp.

Typically the Current Ramp start mode would be used

in two circumstances.

1. For applications where start conditions vary

between starts the Current Ramp mode provides

an optimum soft start irrespective of motor

loading e.g. a conveyor that may start loaded or

unloaded.

Loading...

Loading...