MCD 200 Design Guide

MG.17.C3.02 – VLT is a registered Danfoss trademark 21

Soft Start Application Guide

■ Soft Start Application Guide

■ Application Guide

This section provides data useful in the selection and

application of soft starters.

■

Reduced Voltage Starting

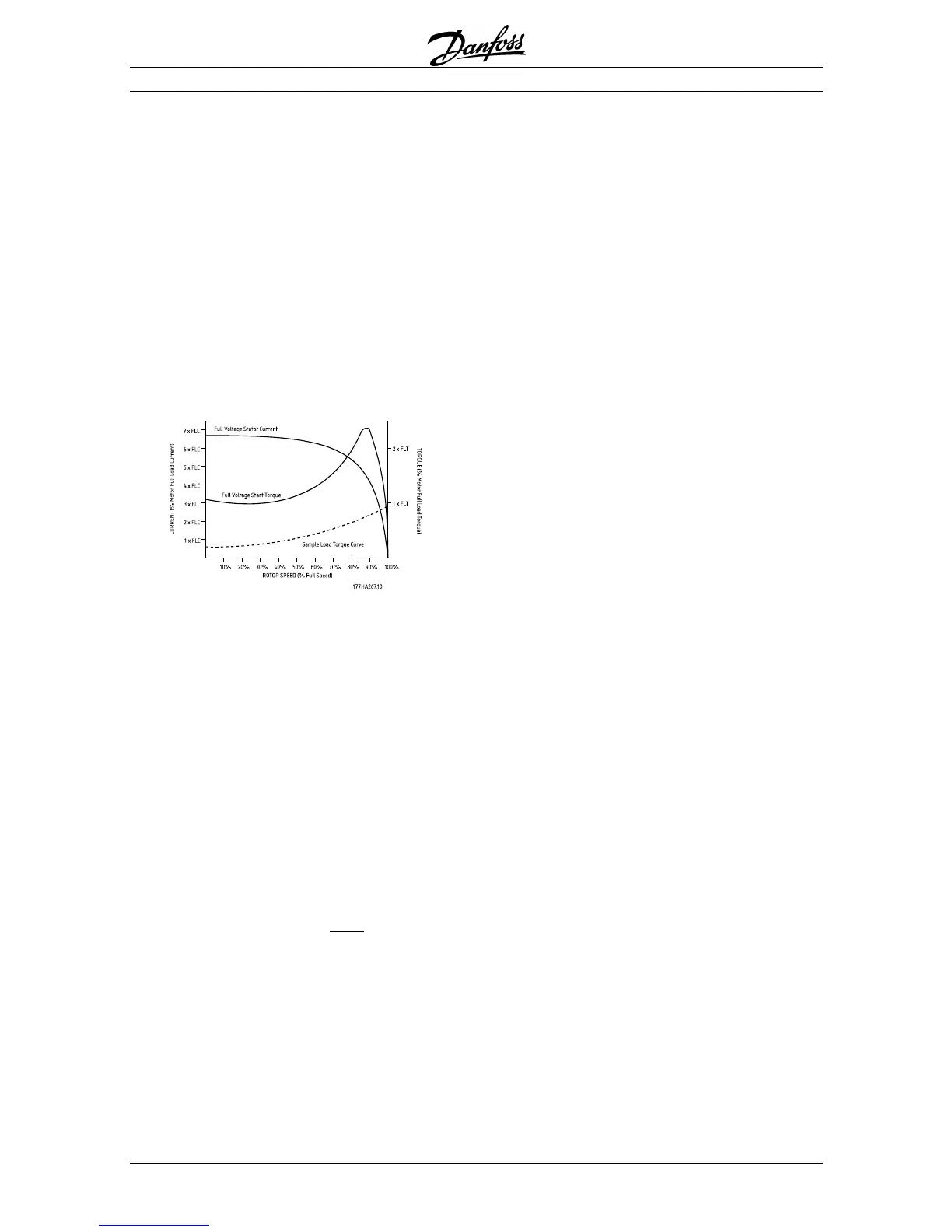

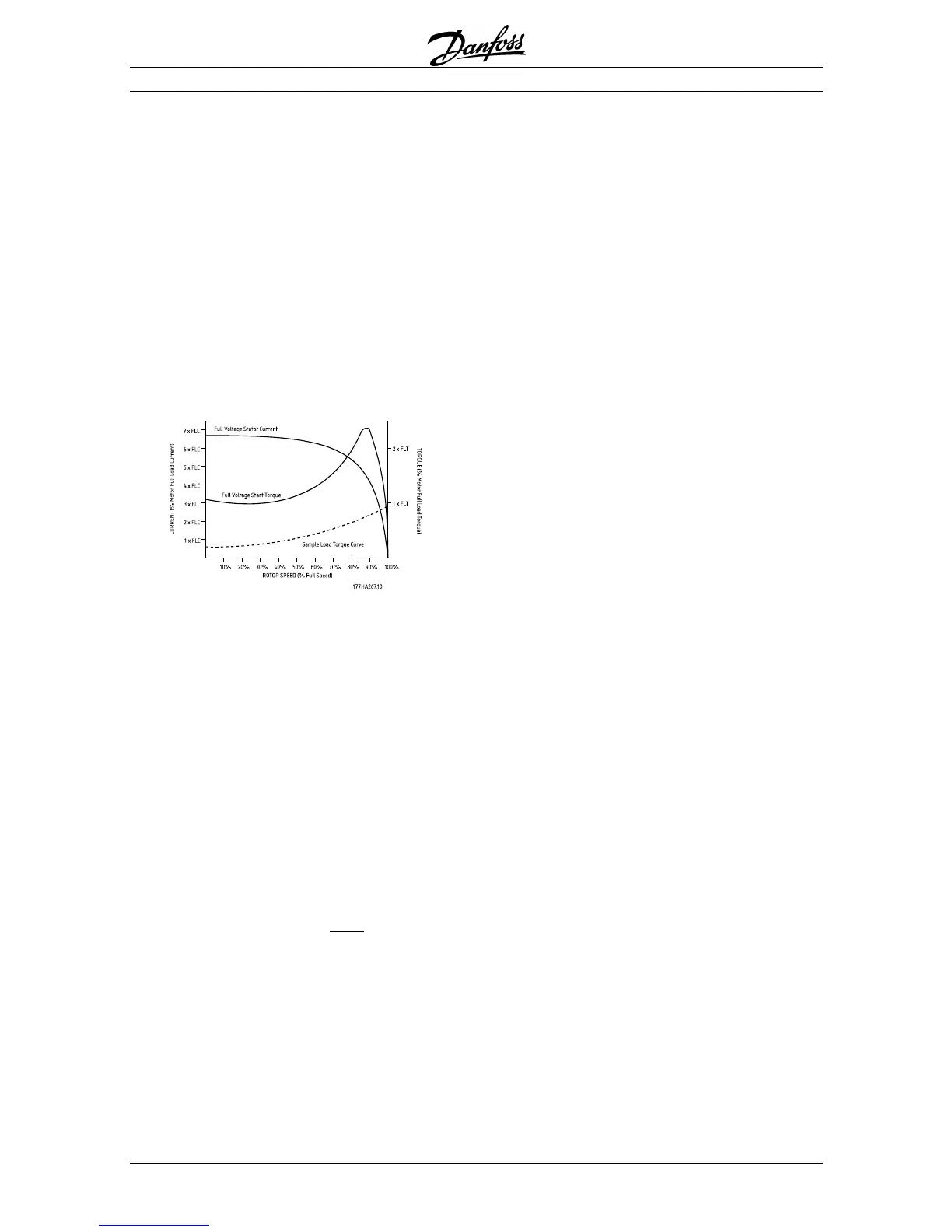

When started under full voltage conditions AC

induction motors initially draw locked rotor current

(LRC) and produce locked rotor torque (LRT). As the

motor accelerates the current falls and the torque

increases to breakdown torque before falling to full

speed levels. Both the magnitude and shape of the

current and torque curves are dependent on motor

design.

Motors with almost identical full speed characteristics

often vary significantly in their starting capabilities.

Locked rotor currents range from as low as 500%, to

in excess of 900% of motor FLC. Locked rotor torques

range from as low as 70%, to highs of around 230%

motor full load torque (FLT).

The motor's full voltage current and torque

characteristics set the limits for what can be achieved

with a reduced voltage starter. For installations in

which either minimising start current or maximising

start torque is critical, it is important to ensure that a

motor with low LRC and high LRT characteristics is

used.

When a reduced voltage starter is used, motor start

torque is reduced according to the following formula.

ST

=

LRT x

I

ST

LRC

(

)

2

T

ST

= Start torque

I

ST

= Start current

LRC = Motor Locked Rotor Current

LRT = Motor Locked Rotor Torque

Start current can be reduced only to the point where

the resulting start torque still exceeds the torque

required by the load. Below this point motor

acceleration will cease and the motor/load will not

reach full speed.

The most common reduced voltage starters are:

• Star/Delta starters

• Auto-transformer starters

• Primary resistance starters

• Soft starters

Star/Delta starting is the cheapest form of reduced

voltage starting, however performance is limited. The

two most significant limitations are:

1. There is no control over the level of current and

torque reduction; these are fixed at one third of

the full voltage levels.

2. There are normally large current and torque

transients as the starter changes from star to

delta. This causes mechanical and electrical

stress often resulting in damage. The transients

occur because as the motor is spinning and then

disconnected from the supply it acts as a

generator with output voltage which may be at the

same amplitude as the supply. This voltage is still

present when the motor is reconnected in delta

configuration, and can be exactly out of phase.

The result is a current of up to twice locked rotor

current and four times locked rotor torque.

Auto-transformer starting offers more control than the

star/delta method, however voltage is still applied in

steps. Limitations of auto-transformer starting include:

1. Torque transients caused by switching between

voltages.

2. Limited number of output voltage taps restricts

the ability to closely select the ideal starting

current.

3. High price for models suitable for frequent or

extended starting conditions.

4. Cannot provide an effective reduced voltage start

for loads with varying start requirements. For

instance, a material conveyor may start loaded or

unloaded. The auto-transformer starter can only

be optimised for one condition.

Primary resistance starters also provide greater

starting control than star/delta starters. However, they

do have a number of characteristics that reduce their

effectiveness. These include:

1. Difficult to optimise start performance when

commissioning because the resistance value must

be calculated when the starter is manufactured

and is not easily changed later.

2. Poor performance in frequent starting situations

because the resistance value changes as heat is

generated in the resistors during a start. A long

cool down period is required between starts.

Loading...

Loading...