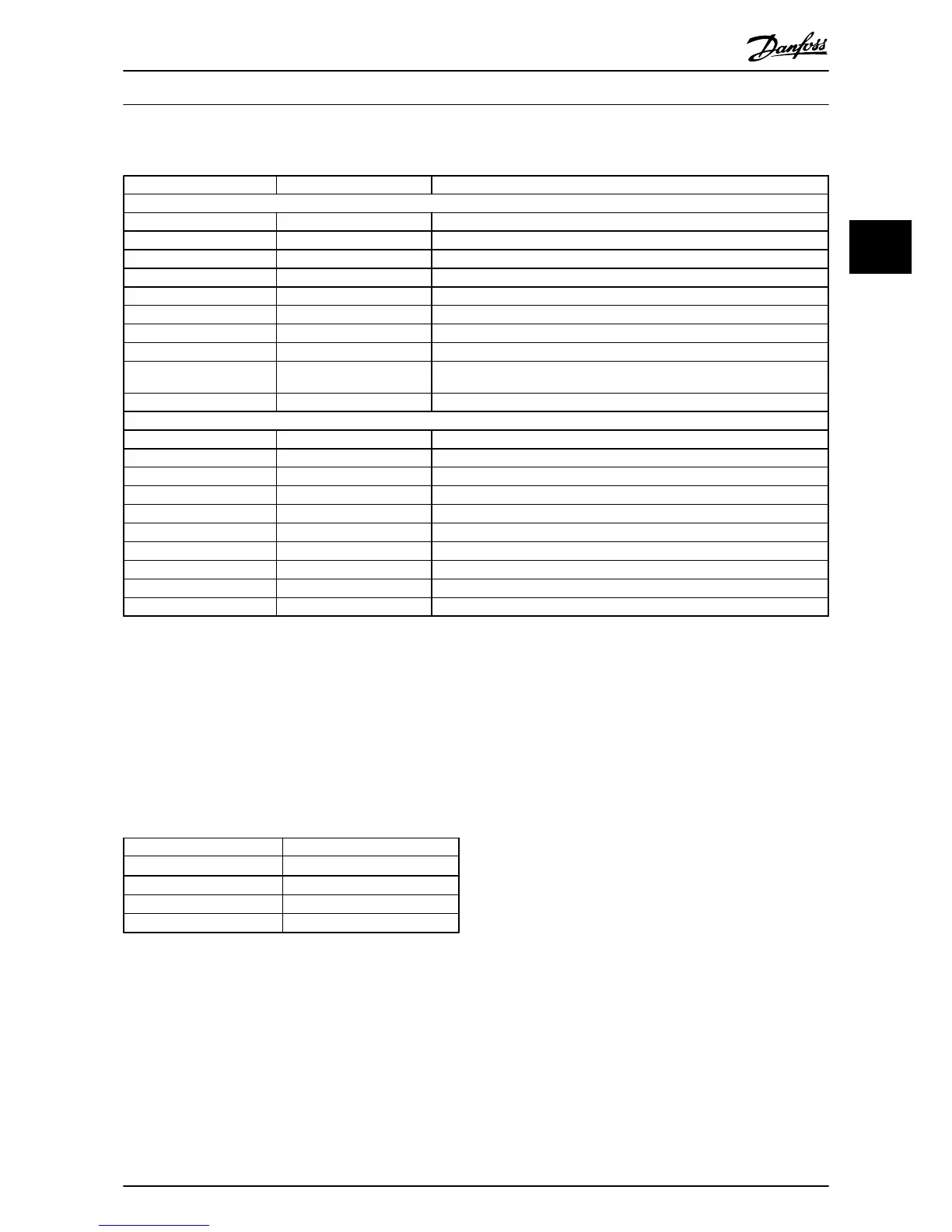

3.3.14 Mains Disconnectors, 12-Pulse

Frame size Power Type

380-500 V

F9 P250 ABB OETL-NF600A

F9 P315 ABB OETL-NF600A

F9 P355 ABB OETL-NF600A

F9 P400 ABB OETL-NF600A

F11 P450 ABB OETL-NF800A

F11 P500 ABB OETL-NF800A

F11 P560 ABB OETL-NF800A

F11 P630 ABB OT800U21

F13 P710 Merlin Gerin NPJF36000S12AAYP

F13 P800 Merlin Gerin NPJF36000S12AAYP

525-690 V

F9 P355 ABB OT400U12-121

F9 P400 ABB OT400U12-121

F9 P500 ABB OT400U12-121

F9 P560 ABB OT400U12-121

F11 P630 ABB OETL-NF600A

F11 P710 ABB OETL-NF600A

F11 P800 ABB OT800U21

F13 P900 ABB OT800U21

F13 P1M0 Merlin Gerin NPJF36000S12AAYP

F13 P1M2 Merlin Gerin NPJF36000S12AAYP

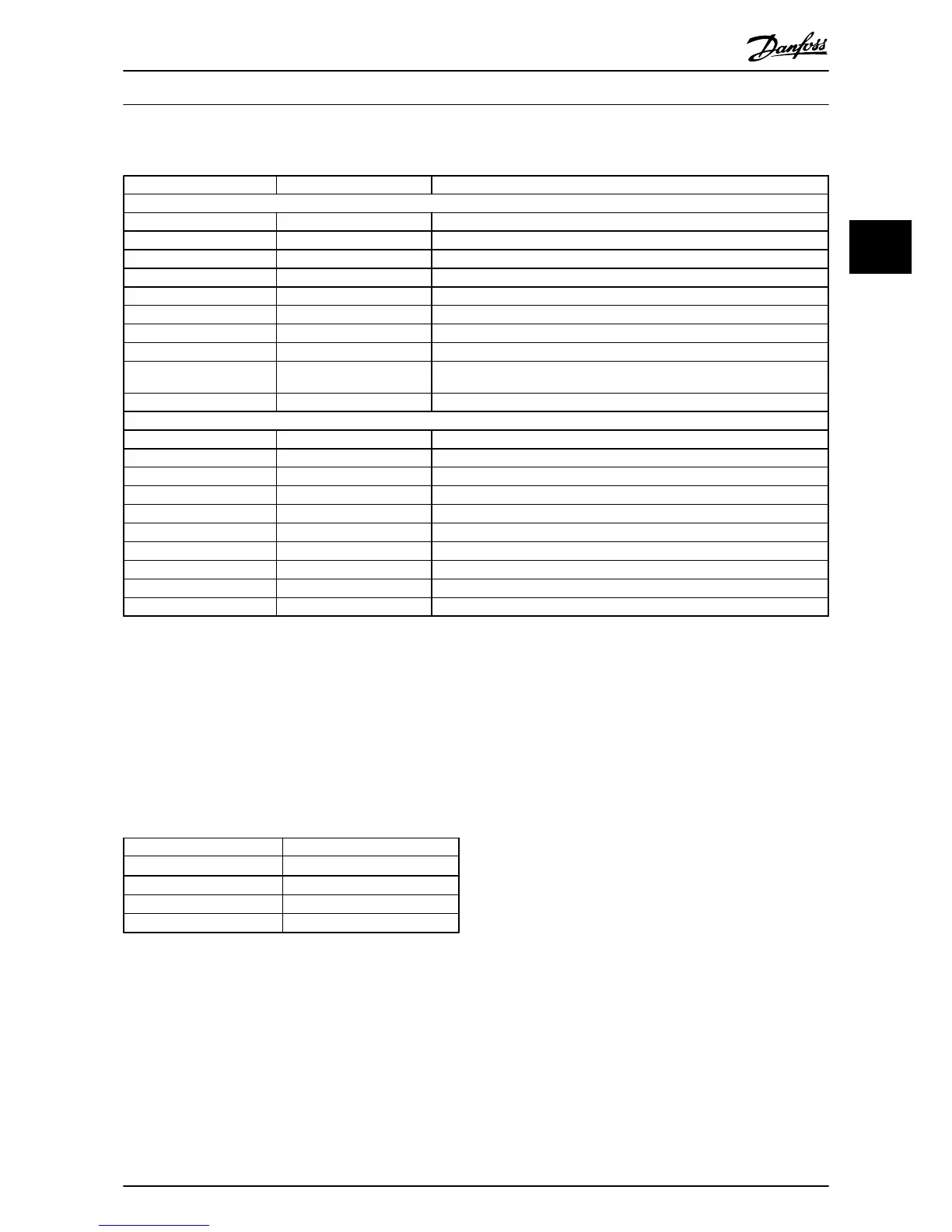

3.3.15 Motor Insulation

For motor cable lengths ≤ the maximum cable length

listed in the General Specifications tables, 5.1.1 Cable

Lengths and Cross Sections, the following motor insulation

ratings are recommended because the peak voltage can be

up to twice the DC link voltage, 2.8 times the mains

voltage, due to transmission line effects in the motor

cable. If a motor has lower insulation rating, it is

recommended to use a dU/dt or sine wave filter.

Nominal Mains Voltage [V] Motor Insulation [V]

U

N

≤ 420

Standard U

LL

= 1300

420 < U

N

≤ 500 Reinforced U

LL

= 1600

500 < U

N

≤ 600 Reinforced U

LL

= 1800

600 < U

N

≤ 690 Reinforced U

LL

= 2000

3.3.16 Motor Bearing Currents

All motors installed with FC 302 250 kW or higher power

drives should have NDE (Non-Drive End) insulated bearings

installed to eliminate circulating bearing currents. To

minimize DE (Drive End) bearing and shaft currents proper

grounding of the frequency converter, motor, driven

machine, and motor to the driven machine is required.

Standard Mitigation Strategies:

1. Use an insulated bearing

2. Apply rigorous installation procedures

- Ensure the motor and load motor are

aligned

- Strictly follow the EMC Installation

guideline

- Reinforce the PE so the high frequency

impedance is lower in the PE than the

input power leads

- Provide a good high frequency

connection between the motor and the

frequency converter for instance by

screened cable which has a 360°

connection in the motor and the

frequency converter

- Make sure that the impedance from

frequency converter to building ground

is lower that the grounding impedance

of the machine. This can be difficult for

pumps

- Make a direct earth connection between

the motor and load motor

3. Lower the IGBT switching frequency

How to Install

VLT

®

Automation Drive FC 300 12-Pulse

Operating Instructions High Power

MG34Q202 - VLT

®

is a registered Danfoss trademark 45

3

3

Loading...

Loading...