4.

Modify the inverter waveform, 60° AVM vs.

SFAVM

5. Install a shaft grounding system or use an

isolating coupling

6. Apply conductive lubrication

7. Use minimum speed settings if possible

8. Try to ensure the line voltage is balanced to

ground. This can be difficult for IT, TT, TN-CS or

Grounded leg systems

9. Use a dU/dt or sinus filter

3.3.17

Brake Resistor Temperature Switch

Torque: 0.5-0.6 Nm (5 in-lbs)

Screw size: M3

This input can be used to monitor the temperature of an

externally connected brake resistor. If the input between

104 and 106 is established, the frequency converter will

trip on warning/alarm 27, “Brake IGBT”. If the connection is

closed between 104 and 105, the frequency converter will

trip on warning/alarm 27, “Brake IGBT”.

A KLIXON switch must be installed that is `normally

closed'. If this function is not used, 106 and 104 must be

short-circuited together.

Normally closed: 104-106 (factory installed jumper)

Normally open: 104-105

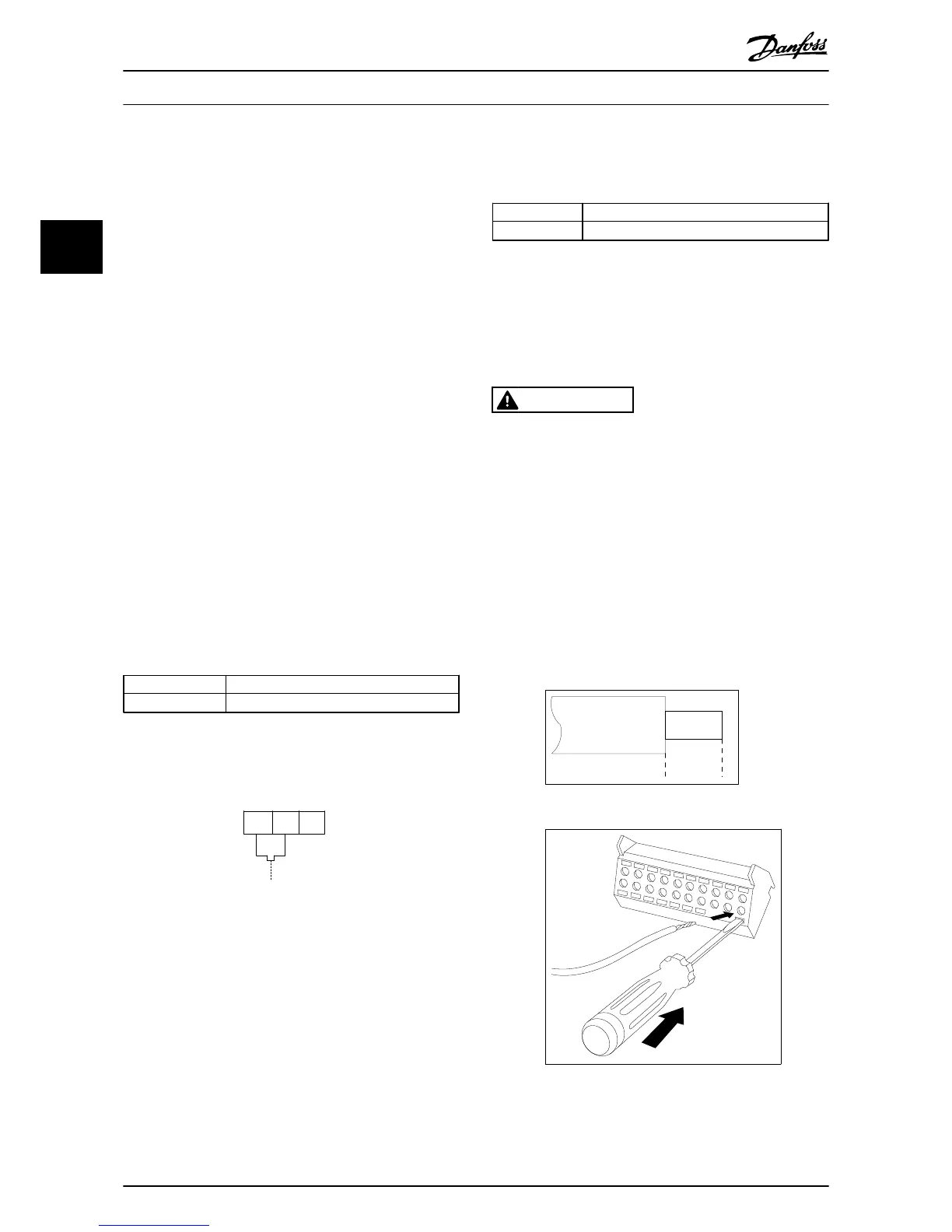

Terminal No.

Function

106, 104, 105 Brake resistor temperature switch.

If the temperature of the brake resistor gets too high and

the thermal switch drops out, the frequency converter will

stop braking. The motor will start coasting.

175ZA877.10

106

NC

104

C

105

NO

3.3.18 Control Cable Routing

Tie down all control wires to the designated control cable

routing as shown in the picture. Remember to connect the

shields in a proper way to ensure optimum electrical

immunity.

Fieldbus connection

Connections are made to the relevant options on the

control card. For details, see the relevant fieldbus

instruction. The cable must be placed in the provided path

inside the frequency converter and tied down together

with other control wires.

Installation of 24 V external DC Supply

Torque: 0.5 - 0.6 Nm (5 in-lbs)

Screw size: M3

No. Function

35 (-), 36 (+) 24 V external DC supply

24 V DC external supply can be used as low-voltage supply

to the control card and any option cards installed. This

enables full operation of the LCP (including parameter

setting) without connection to mains. A warning of low

voltage is given when 24 V DC has been connected;

however, there is no tripping.

WARNING

Use 24 V DC supply of type PELV to ensure correct

galvanic isolation (type PELV) on the control terminals of

the frequency converter.

3.3.19 Access to Control Terminals

All terminals to the control cables are located beneath the

LCP. They are accessed by opening the door of the IP21/

54 version or removing the covers of the IP00 version.

3.3.20

Electrical Installation, Control

Terminals

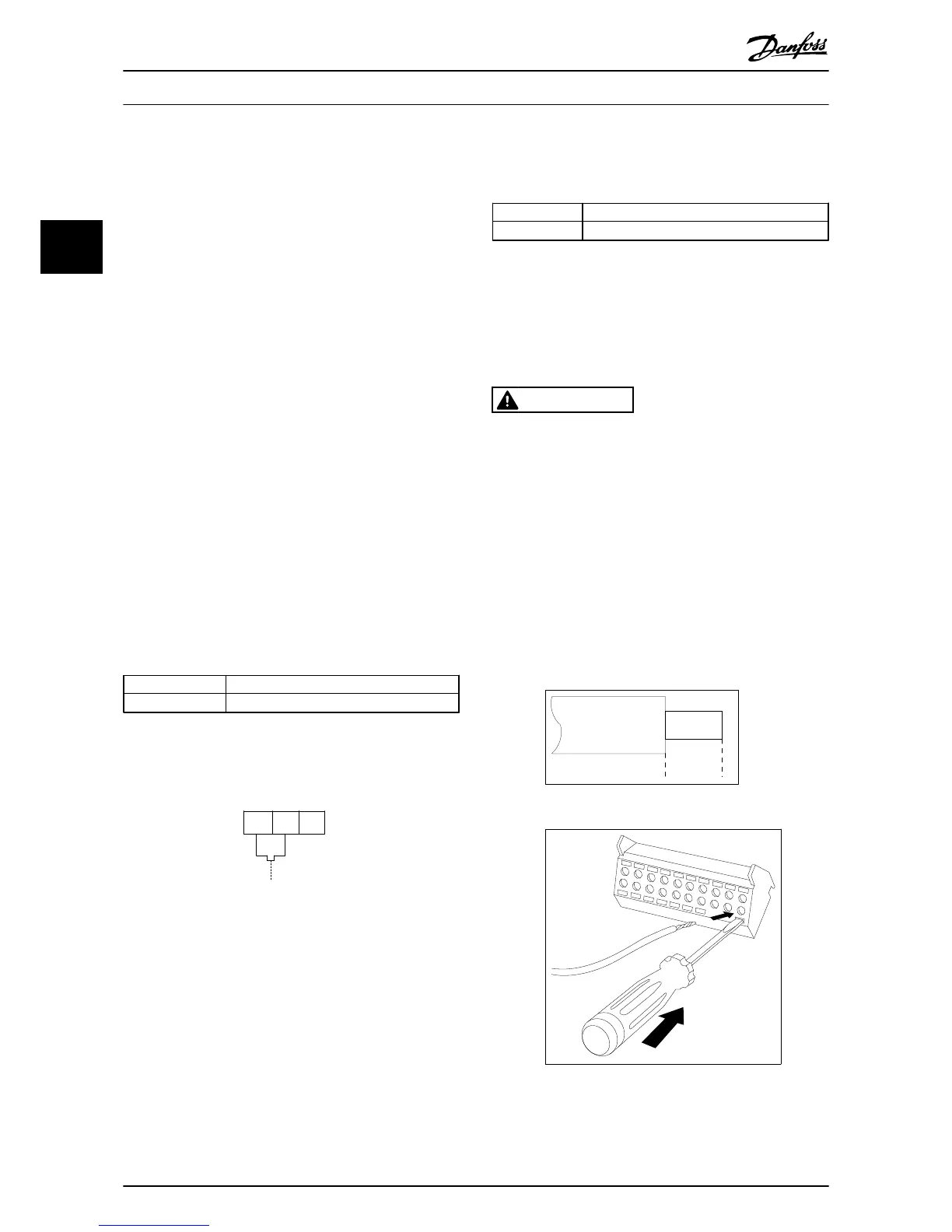

To connect the cable to the terminal:

1. Strip insulation by about 9-10 mm

130BA150.10

9 - 10 mm

(0.37 in)

2.

Insert a screwdriver

1)

in the square hole.

3. Insert the cable in the adjacent circular hole.

4. Remove the screwdriver. The cable is now

mounted in the terminal.

To remove the cable from the terminal:

1.

Insert a screw driver

1)

in the square hole.

How to Install

VLT

®

Automation Drive FC 300 12-Pulse

Operating Instructions High Power

46 MG34Q202 - VLT

®

is a registered Danfoss trademark

3

3

Loading...

Loading...