1.1 Purpose of the Manual

This manual is intended to provide detailed information for

the installation and start-up of the adjustable frequency

drive. chapter 2 Installation provides requirements for

mechanical and electrical installation, including input,

motor, control and serial communications wiring and

control terminal functions. chapter 3 Start-up and Functional

Test provides detailed procedures for start-up, basic

operational programming, and functional testing. The

remaining chapters provide supplementary details. These

details include user interface, detailed programming,

application examples, start-up troubleshooting, and specifi-

cations.

1.2 Product Overview

An adjustable frequency drive is an electronic motor

controller that converts AC line power input into a variable

AC waveform output. The frequency and voltage of the

output are regulated to control the motor speed or torque.

The adjustable frequency drive can vary the speed of the

motor in response to system feedback, such as changing

temperature or pressure for controlling fan, compressor, or

pump motors. The adjustable frequency drive can also

regulate the motor by responding to remote commands

from external controllers.

In addition, the adjustable frequency drive monitors the

system and motor status, issues warnings or alarms for

fault conditions, starts and stops the motor, optimizes

energy efficiency, and offers many more control,

monitoring, and efficiency functions. Operation and

monitoring functions are available as status indications to

an outside control system or serial communication

network.

1.3

Internal Adjustable Frequency Drive

Controller Functions

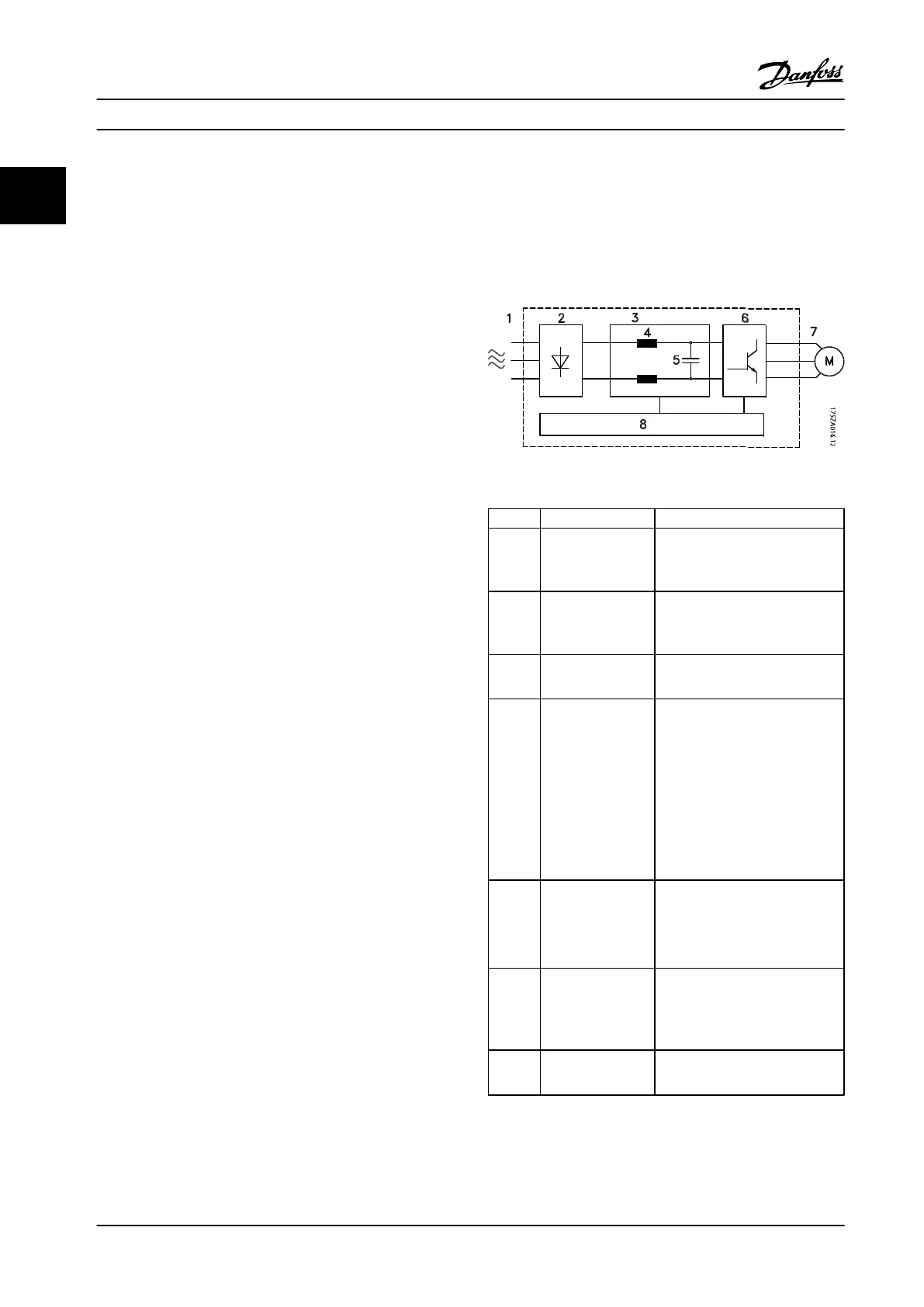

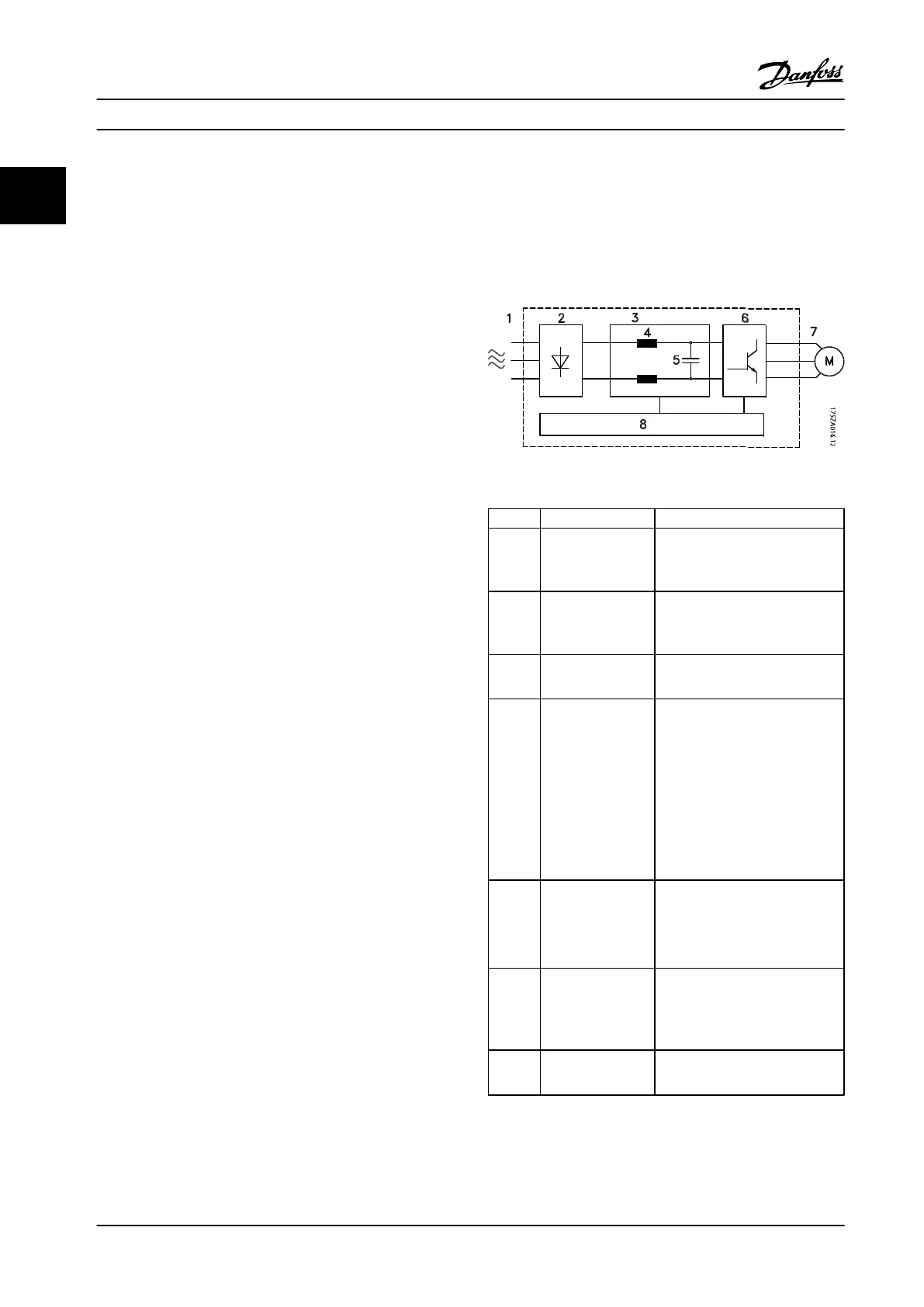

Figure 1.3 is a block diagram of the adjustable frequency

drive's internal components. See Table 1.3 for their

functions.

Figure 1.3 Adjustable Frequency Drive Block Diagram

Area Title Functions

1 Line power input

•

Three-phase AC line power

supply to the adjustable

frequency drive

2 Rectifier

•

The rectifier bridge converts

the AC input to DC current to

supply inverter power

3 DC bus

•

Intermediate DC bus circuit

handles the DC current

4 DC reactors

•

Filter the intermediate DC

circuit voltage

•

Prove line transient protection

•

Reduce RMS current

•

Raise the power factor

reflected back to the line

•

Reduce harmonics on the AC

input

5 Capacitor bank

•

Stores the DC power

•

Provides ride-through

protection for short power

losses

6 Inverter

•

Converts the DC into a

controlled PWM AC waveform

for a controlled variable

output to the motor

7 Output to motor

•

Regulated three-phase output

power to the motor

Introduction Instruction Manual

6 Danfoss A/S © Rev. 2014-02-10 All rights reserved. MG16E222

11

Loading...

Loading...