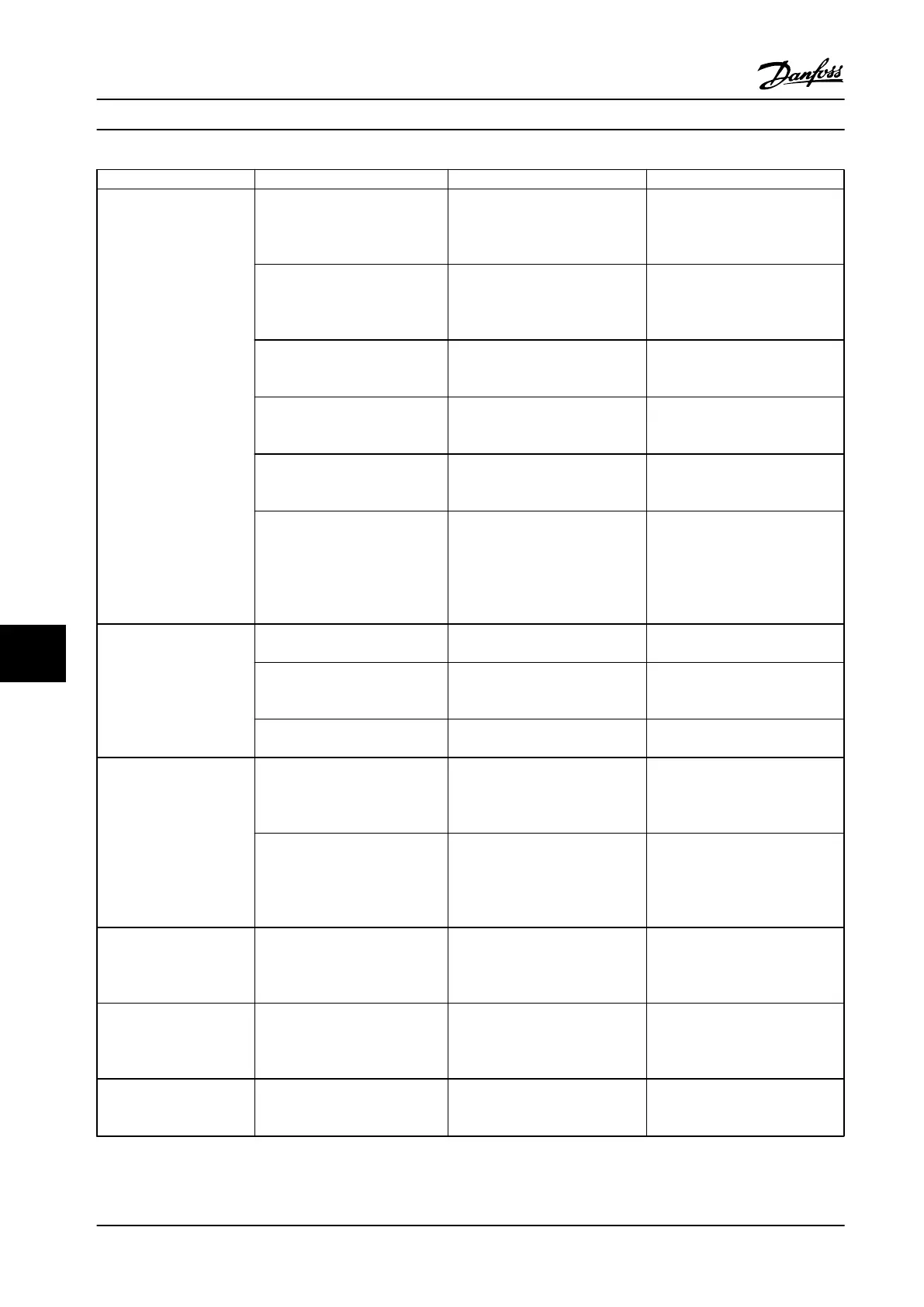

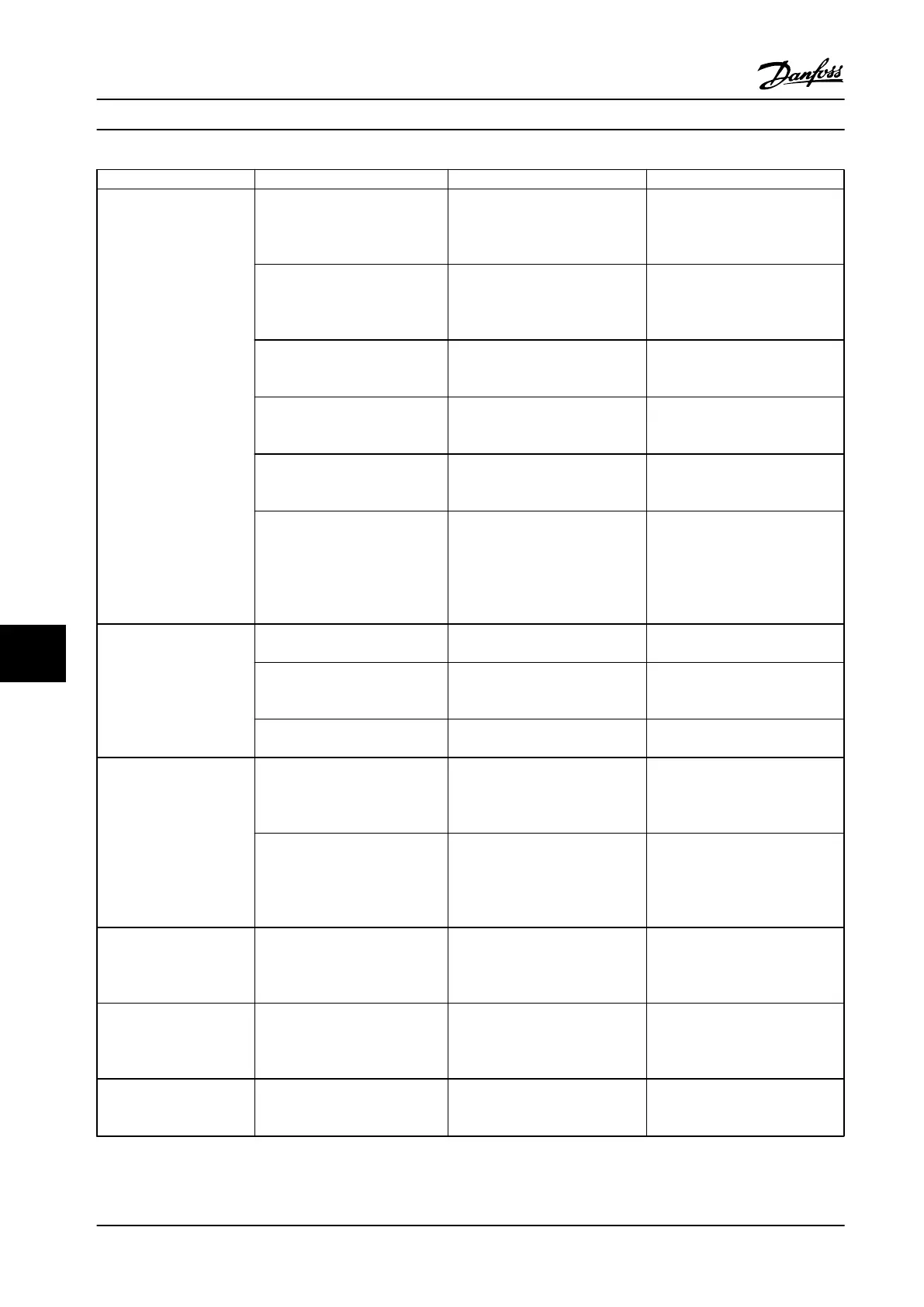

Symptom Possible Cause Test Solution

Motor not running

Service switch open or missing

motor connection

Check if the motor is connected

and the connection is not

interrupted (by a service switch or

other device).

Connect the motor and check the

service switch.

No line power with 24 V DC

option card

If the display is functioning but no

output, check that line power is

applied to the adjustable frequency

drive.

Apply line power to run the unit.

LCP Stop Check if [Off] has been pressed. Press [Auto On] or [Hand On]

(depending on operation mode) to

run the motor.

Missing start signal (Standby)

Check 5-10 Terminal 18 Digital Input

for correct setting for terminal 18

(use default setting).

Apply a valid start signal to start

the motor.

Motor coast signal active

(Coasting)

Check 5-12 Coast inv. for correct

setting for terminal 27 (use default

setting).

Apply 24 V on terminal 27 or

program this terminal to No

operation.

Wrong reference signal source Check reference signal: Local,

remote or bus reference? Preset

reference active? Terminal

connection correct? Scaling of

terminals correct? Reference signal

available?

Program correct settings. Check

3-13 Reference Site. Set preset

reference active in parameter

group 3-1* References. Check for

correct wiring. Check scaling of

terminals. Check reference signal.

Motor running in wrong

direction

Motor rotation limit

Check that 4-10 Motor Speed

Direction is programmed correctly.

Program correct settings.

Active reversing signal Check if a reversing command is

programmed for the terminal in

parameter group 5-1* Digital inputs.

Deactivate reversing signal.

Wrong motor phase connection

See chapter 3.7 Check Motor

Rotation in this manual.

Motor is not reaching

maximum speed

Frequency limits set wrong

Check output limits in 4-13 Motor

Speed High Limit [RPM], 4-14 Motor

Speed High Limit [Hz] and 4-19 Max

Output Frequency.

Program correct limits.

Reference input signal not scaled

correctly

Check reference input signal

scaling in 6-* Analog I/O mode and

parameter group 3-1* References.

Reference limits in parameter

group 3-0* Reference limits.

Program correct settings.

Motor speed unstable

Possible incorrect parameter

settings

Check the settings of all motor

parameters, including all motor

compensation settings. For closed-

loop operation, check PID settings.

Check settings in parameter group

1-6* Analog I/O mode. For closed-

loop operation, check settings in

parameter group 20-0* Feedback.

Motor runs rough

Possible over-magnetization Check for incorrect motor settings

in all motor parameters.

Check motor settings in parameter

groups 1-2* Motor data, 1-3* Adv

motor data, and 1-5* Load indep.

setting.

Motor will not brake.

Possible incorrect settings in the

brake parameters. Possible too

short ramp-down times.

Check brake parameters. Check

ramp time settings.

Check parameter group 2-0* DC

brake and 3-0* Reference limits.

Basic Troubleshooting Instruction Manual

74 Danfoss A/S © Rev. 2014-02-10 All rights reserved. MG16E222

99

Loading...

Loading...