39

MG.10.J8.02 – VLT is a registered Danfoss trade mark

Programmable SyncPos motion controller

■■

■■

■ Quick Start Tutorial for impatient users

1. Start → "CAM-EDITOR" and load VLT

parameters as cnf file into the CAM-Editor:

"FILE" → "LOAD CNF".

2. Enter gearing factors or set user units MU and

UU.

3. Enter at least three → "FIX POINTS" for

master and slave in the index card with the

same name.

4. Enter → "START STOP POINTS" for the

engaging and disengaging.

5. Define the → "NUMBER OF INTERVALS" for

a master cycle length in the index card

"CURVE DATA".

The → "INTERVAL TIME" in the index card

"CURVE INFO" should not be less than 20 ms.

6. Define the → "SLAVE STOP POSITION" in the

index card "CURVE INFO".

7. Enter the number of → "CYCLES/MIN

MASTER" in the index card "CURVE INFO".

8. Check the velocity and acceleration of the

slave with the help of the diagram.

9. Save curve as cnf file → "SAVE CNF AS" and

load into the VLT.

CAM Control

■■

■■

■ Example: Stamping of boxes with use-by date

The following example explains step by step how

to edit the curve for this application of the CAM

control and then how to incorporate it into your

control program.

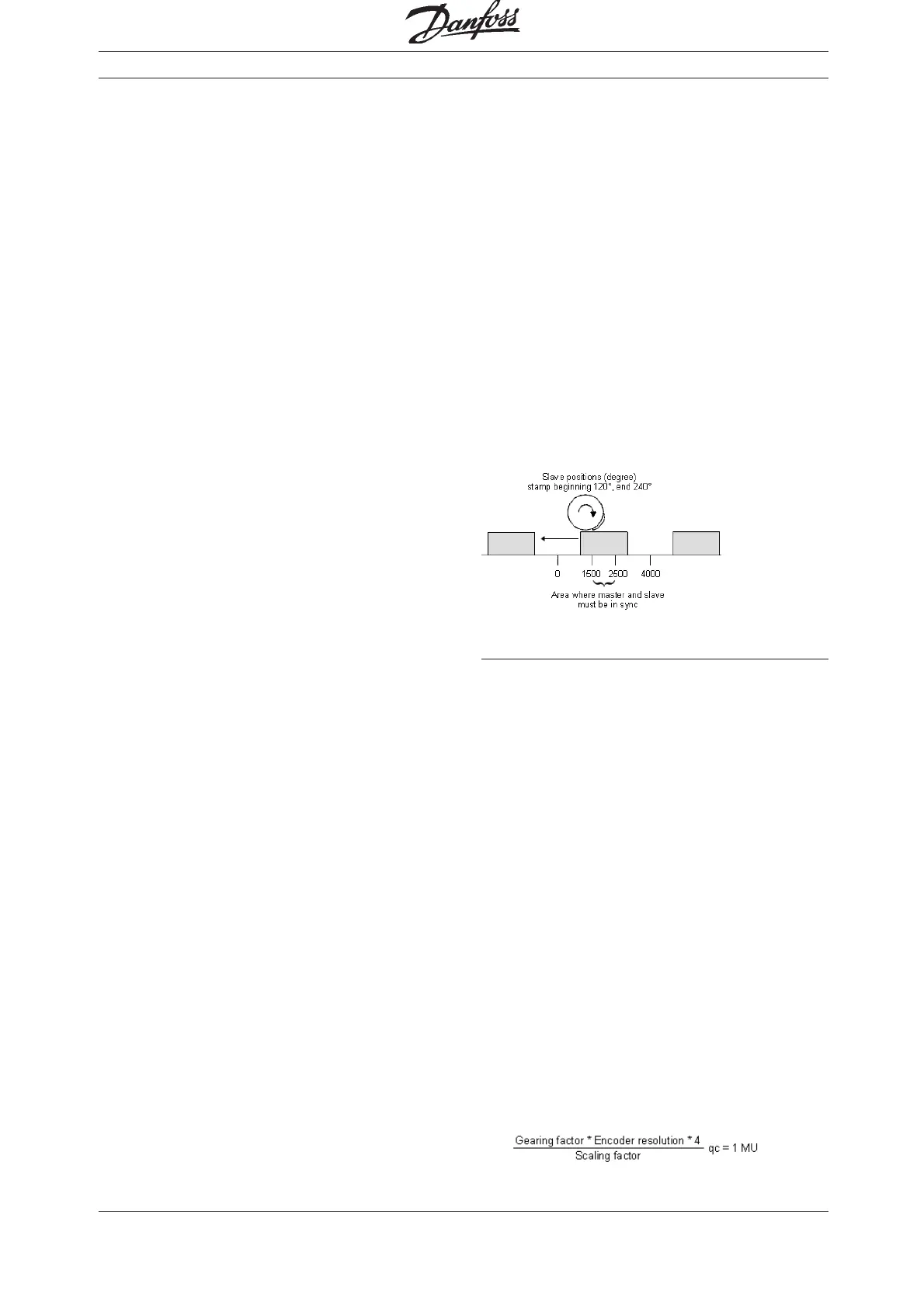

A roller is supposed to stamp an inscription with a

length of 10 cm on cardboard boxes. The stamp

corresponds to a roller section of 120 degrees.

60 cardboard boxes are transported on the con-

veyor belt per minute. The cardboard boxes are

always transported on the conveyor belt at exactly

the same distance from each other (e.g. by means

of a mechanical set pattern). During the printing

process, the stamping roller and the cardboard box

must run in sync:

How to edit the curve step by step

1. Set the VLT with the required parameters and

save these user parameters with

"PARAMETERS" → "SAVE TO FILE" with the

extension „cnf“.

2. Start the → "CAM-EDITOR" and load this cnf

file with File → "LOAD CNF".

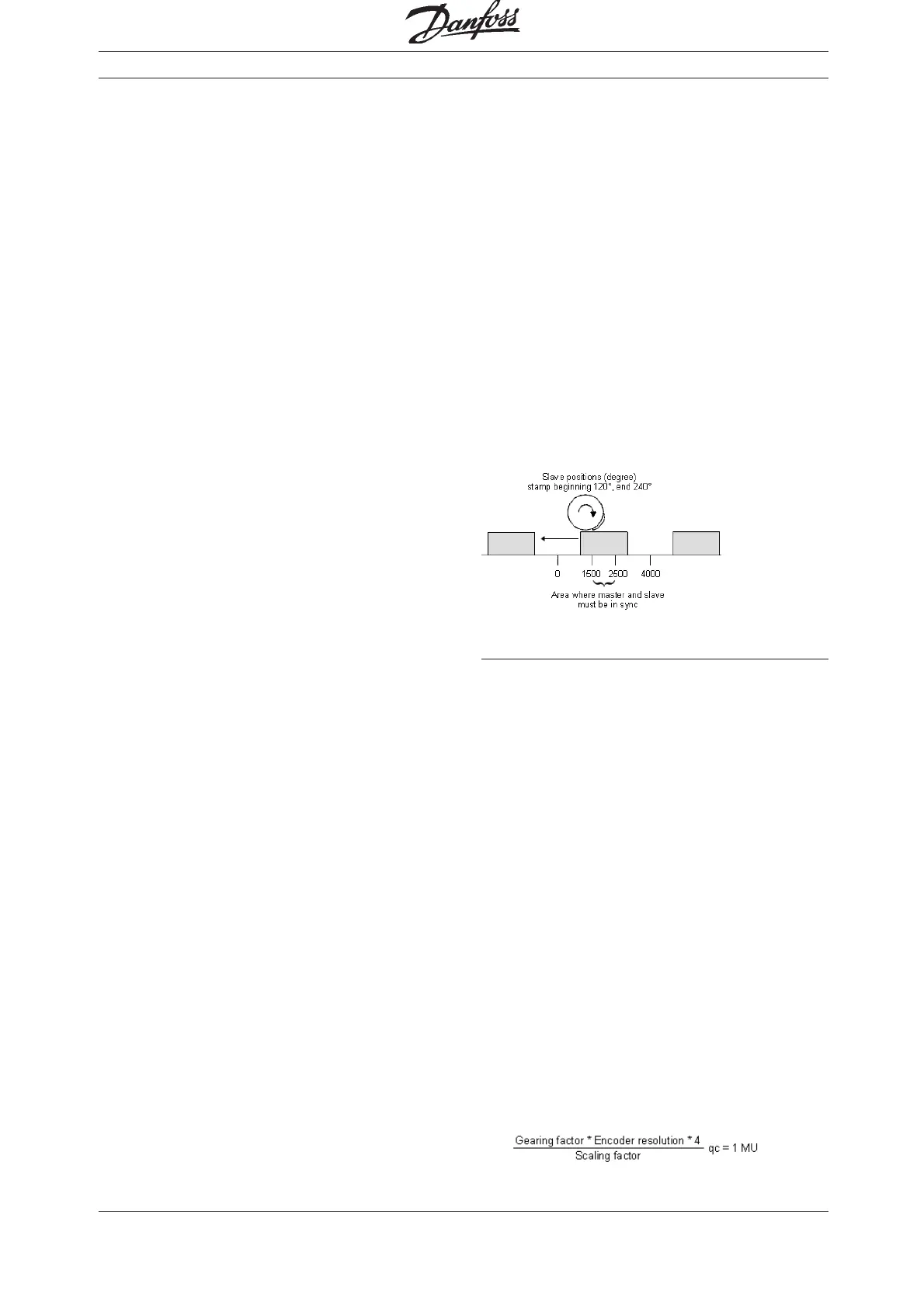

3. Determine the gearing factor of the master in

MU units.

The input should be possible in 1/10 mm

resolution.

The drive is connected with the conveyor belt

by means of a gearing of 25:11; i.e. the motor

makes 25, the drive pulley 11 revolutions.

Gearing factor = 25/11

Incremental encoder directly on the master

drive; encoder resolution = 4096.

The drive pulley has 20 teeth/revolution,

2 teeth correspond to 10 mm, thus 1 revolution

corresponds to = 100 mm conveyor belt feed

or 1000/10 mm.

Thus, the scaling factor is 1000.

Stamping roller = Slave

Conveyor belt = Master

Master positions (1/100 mm)

Loading...

Loading...