Adjustments and Maintenance

2-23

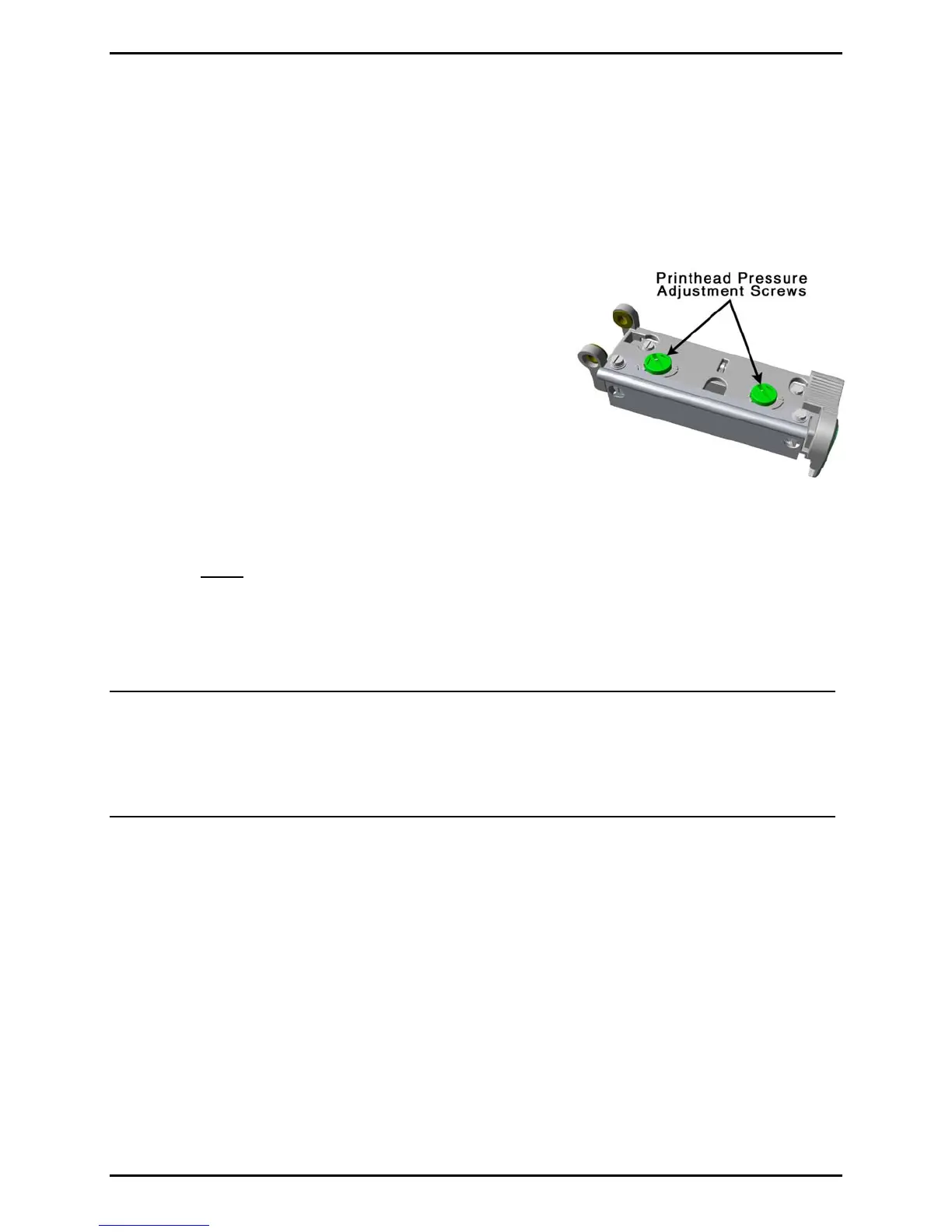

2.5 Printhead Pressure Adjustment

The pressure applied to the media affects print quality. However, a pressure adjustment

should only be performed after attempting to improve print quality using (1) HEAT and/or

(2) PRINT SPEED, and then only by the minimum amount needed for improvement:

1. Load 4-inch (102 mm) wide media and ribbon.

2. Disengage the Media Width Adjustment (its left-most

position); see Section 2.3.

3. Print a Test Label:

• Non-Display Models: Simultaneously press

PAUSE and FEED.

• Display-Equipped Models: Select a Print Quality

Label.

4. Making equal adjustments to each screw to achieve even print contrast across the

media, rotate the Printhead Pressure Adjustment Screws counterclockwise to increase

the pressure or clockwise to decrease the pressure. Set the Media Width Adjustment;

see Section 2.3.

Notes: (1) Narrow thermal transfer media can sometimes require an increased setting

on the left screw to prevent ribbon smudging; (2) Excessive pressure can reduce

the service life of the printhead and platen; and, (3) Unequal pressure may

cause ribbon and label tracking problems.

2.6 Ribbon Path Alignment

When irregular voids extend diagonally through printed images on thermal transfer-

equipped models, the cause may be ribbon overlap (wrinkling). Before performing this

alignment, check other factors which can cause ribbon wrinkle:

• Misadjusted Media Width setting (Section 2.3);

• Misadjusted Printhead Pressure setting (Section 2.5);

• Severely misadjusted Printhead Burn Line (Section 2.4);