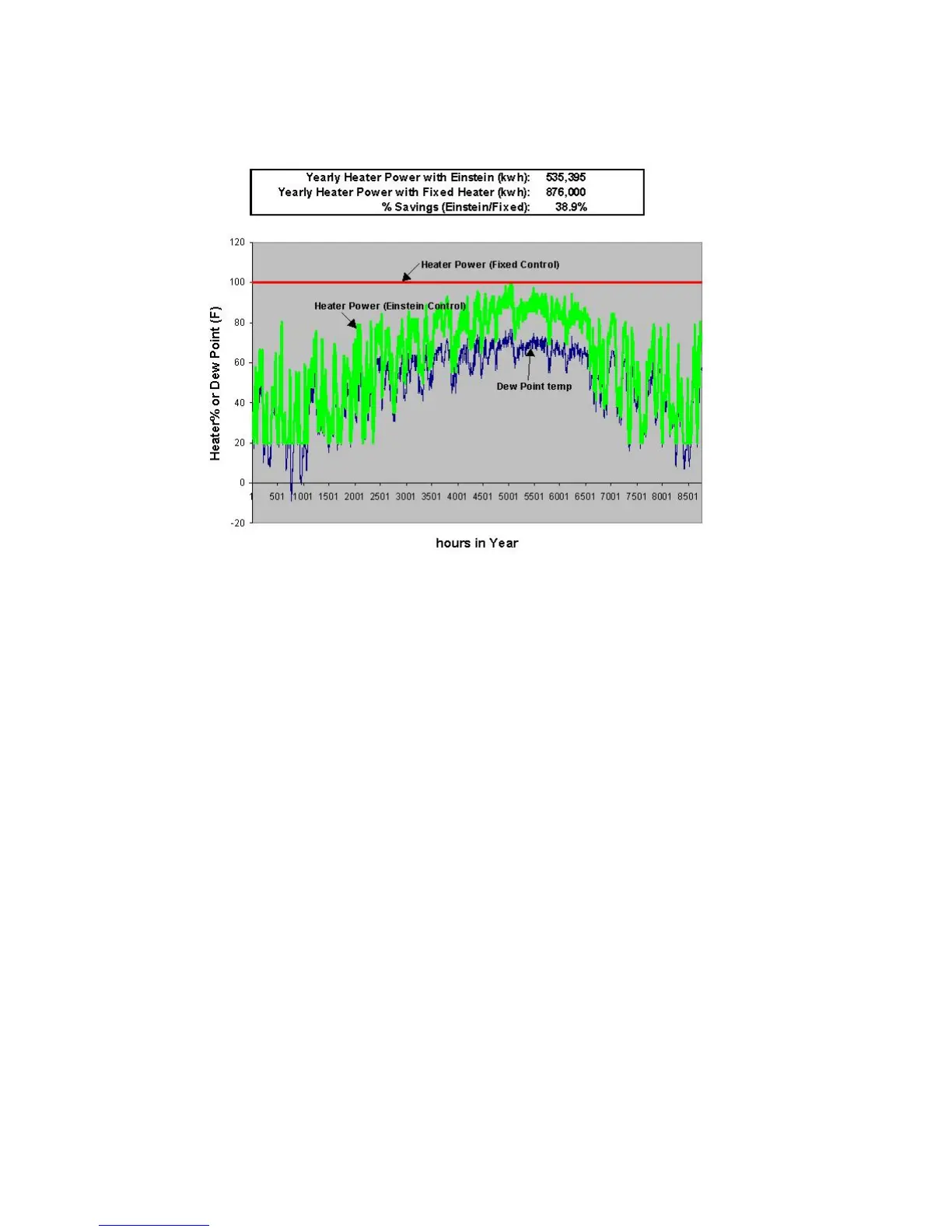

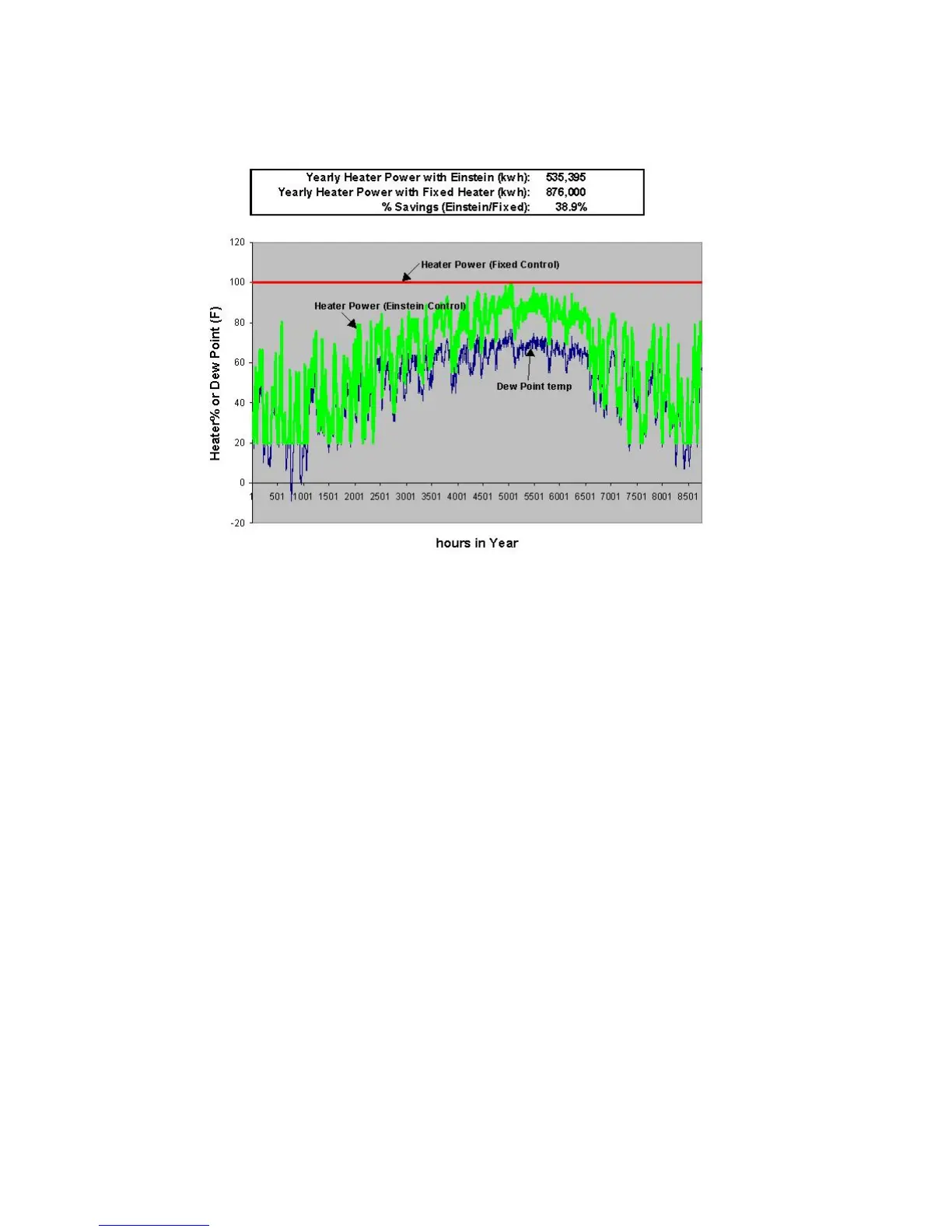

A saving of up to 40% can be obtained for Atlanta weather conditions by implementing

the anti-condensate heater control strategy resident in the standard E2.

Figure 4. Anti-Condensate Heater Power Comparison –Fixed Vs. E2

FIELD TEST

In order to quantify and understand the value of E2 controller in a supermarket

application, a field test was conducted. Two identical stores located within a few miles of

one another were selected. An E2 controller was used to control the refrigeration

systems in one store while conventional supermarket controls were used in the second.

Power meters were provided in both stores to measure refrigeration system and

condenser energy consumption. The test was run for a full year. Refrigeration systems

in the E2-controlled store used ESR control; the non-E2 store’s refrigeration systems

were fitted with EPRs. The field test results are summarized in Table 4 & 5. Table 4

summarizes the energy results and Table 5 provides averages of key parameters.

The following conclusions can be made based on the data collected:

• Overall the store with the E2 controllers consumed 17.5% less energy than the

non-E2 store.

• Condenser power for each rack was always lower for the E2-controlled store and

its average condenser pressure was higher. This is because the E2 TD control

algorithm optimized the total fan & rack power by floating the condenser

pressure. The non-E2 store always had more condenser fan on than the E2

store, and somewhat lower condensing pressures, but the resulting higher

condenser fan power was not fully offset by lower compressor energy usage. TD

control via E2 automatically optimizes the condenser fan versus compressor

power balance for every refrigeration system, under all conditions.

Page 12 of 15

Loading...

Loading...