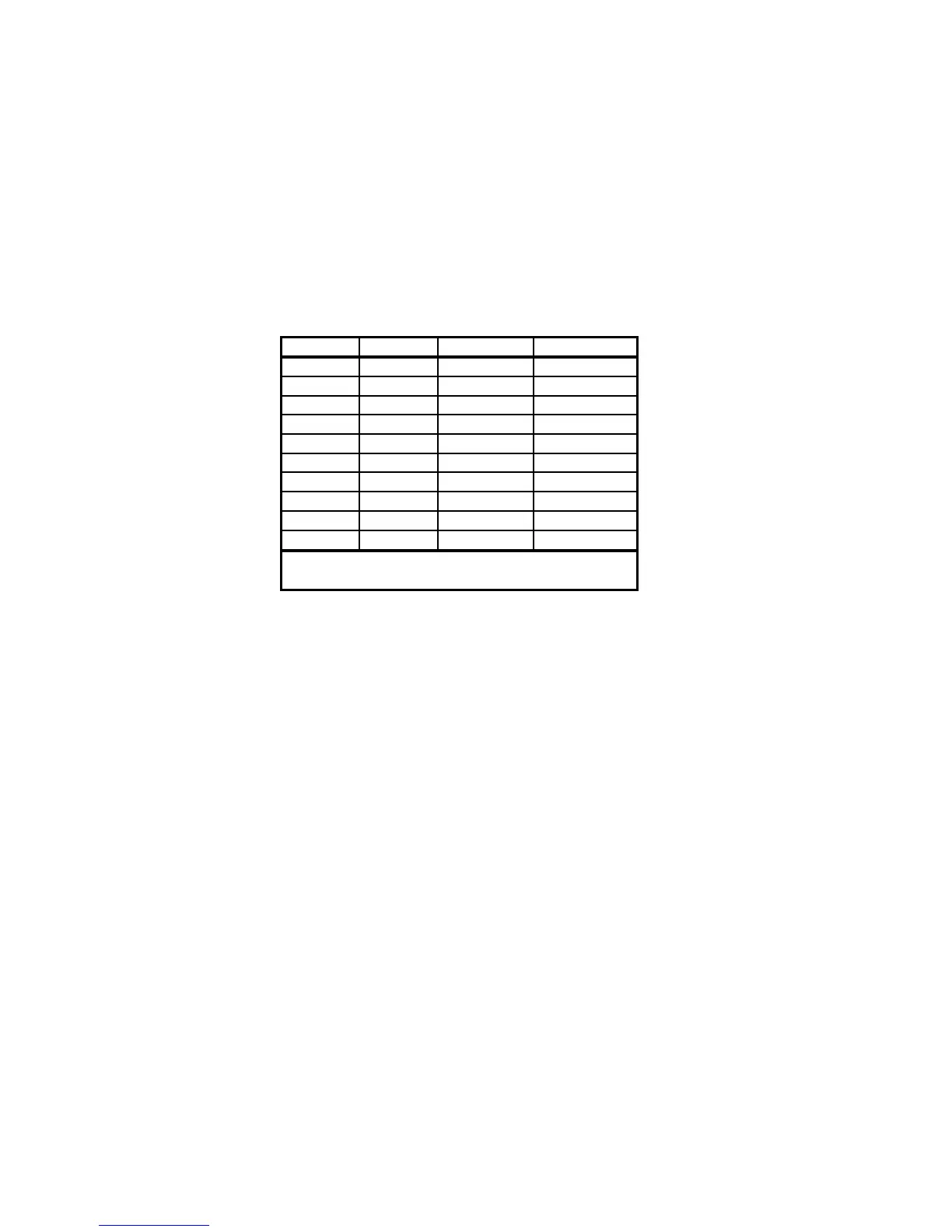

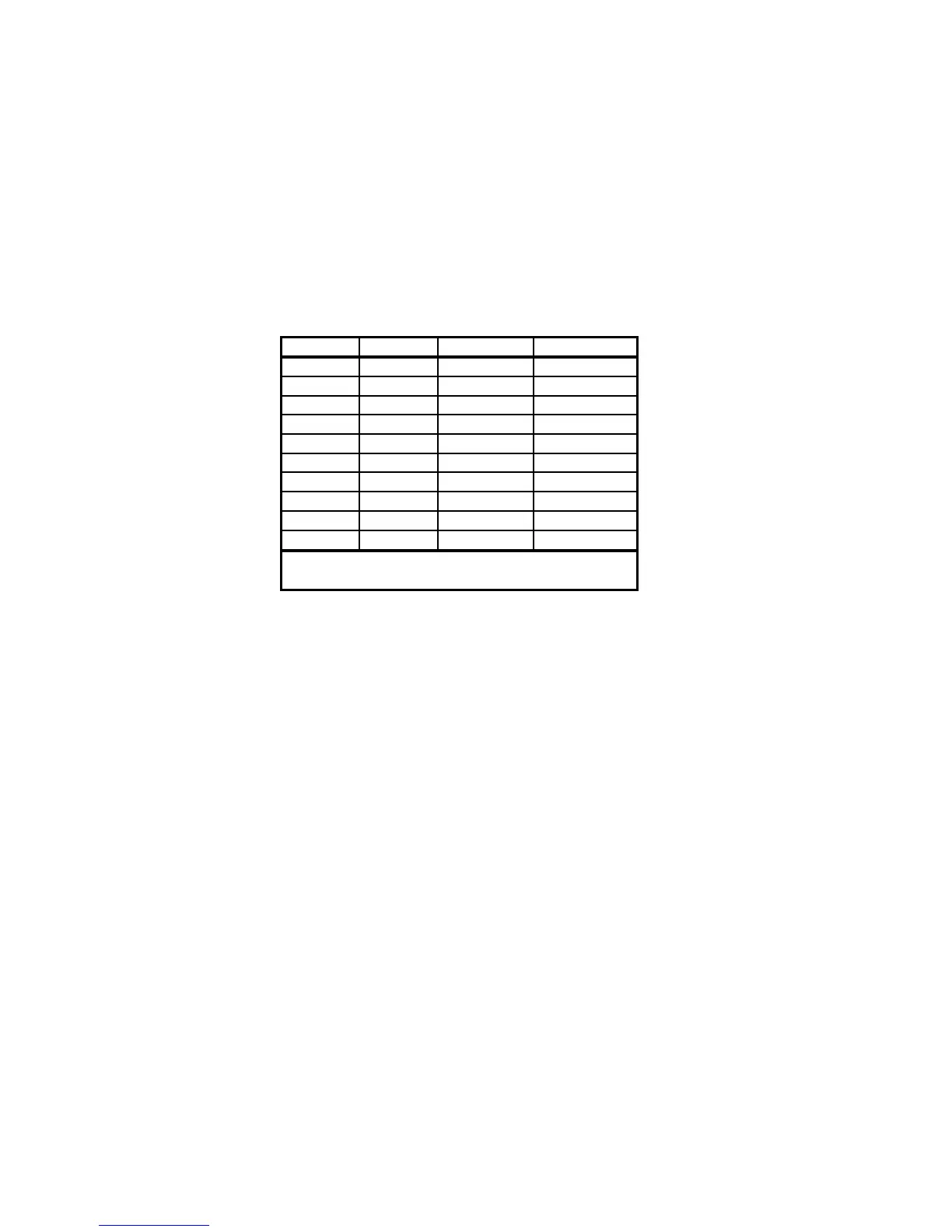

pressure can affect compressor power for the same example system as used to

generate the data in Table 1. The far right column in Table 2 shows the

percentage increase in compressor power as discharge pressure and saturated

discharge temperature (Tdsat) is increased. It can be also observed that

increases in discharge pressure result in higher energy usage for lower

temperature refrigeration systems. From this data, a second rule of thumb can

be drawn -

“for every 1 psig decrease in discharge pressure, compressor power

is reduced approximately 0.5%.”

Table 2: Effect of discharge pressure on compressor power.

It should be further noted that compressor discharge pressure is always a

function of and higher than condensing pressure, and that other system elements can

substantially elevate discharge pressures above levels enforced by ambient

temperatures and resulting condensing temperatures and pressures alone. These

include gas defrost discharge pressure regulators and heat reclaim system valves,

piping, and controls. Whether an increase in discharge pressure is imposed by a rise in

ambient temperature or by the action of refrigeration system elements, the efficiency and

energy penalties are the same.

Having reviewed the parameters that affect compressor power and system

efficiency, we can now explain how E2 controllers are designed to apply these basic

principles to refrigeration systems in order to minimize refrigeration system power

consumption.

Tdsat (F) Pd (Psig) Comp. kW %kW/psig

70 128.1 20.14 0.65%

75 132.3 20.69 0.62%

80 143.7 22.16 0.57%

85 155.7 23.68 0.51%

90 168.5 25.24 0.48%

95 181.9 26.86 0.44%

100 196 28.52 0.41%

105 210.8 30.25 0.38%

110 226.4 32.03 0.35%

115 242.8 33.89 0.34%

Calculations done using refrigeration model with following conditions:

- R-22, Sat. Suction Temp=-10 F, Case load = 200,000 Btu/hr

HIGH SIDE CONTROL WITH E2.

Most mechanical and electronic control systems cycle condenser cooling fans to

on and off in order to maintain fixed high side condensing and operating pressures and

resulting saturated condensing temperatures (typically 90 degF), even when outdoor

ambient temperatures may permit condensing pressures to drop (float) to lower levels.

E2 controllers

include resident control strategies that let one take advantage of lower

ambient temperatures to reduce refrigeration system compressor power. When

operated utilizing E2’s TD (where TD = the temperature difference between ambient air

temperature and condensing temperature) condenser fan control strategy, E2s permit

refrigeration system operation at the lowest condenser pressure possible with minimum

Page 5 of 15

Loading...

Loading...