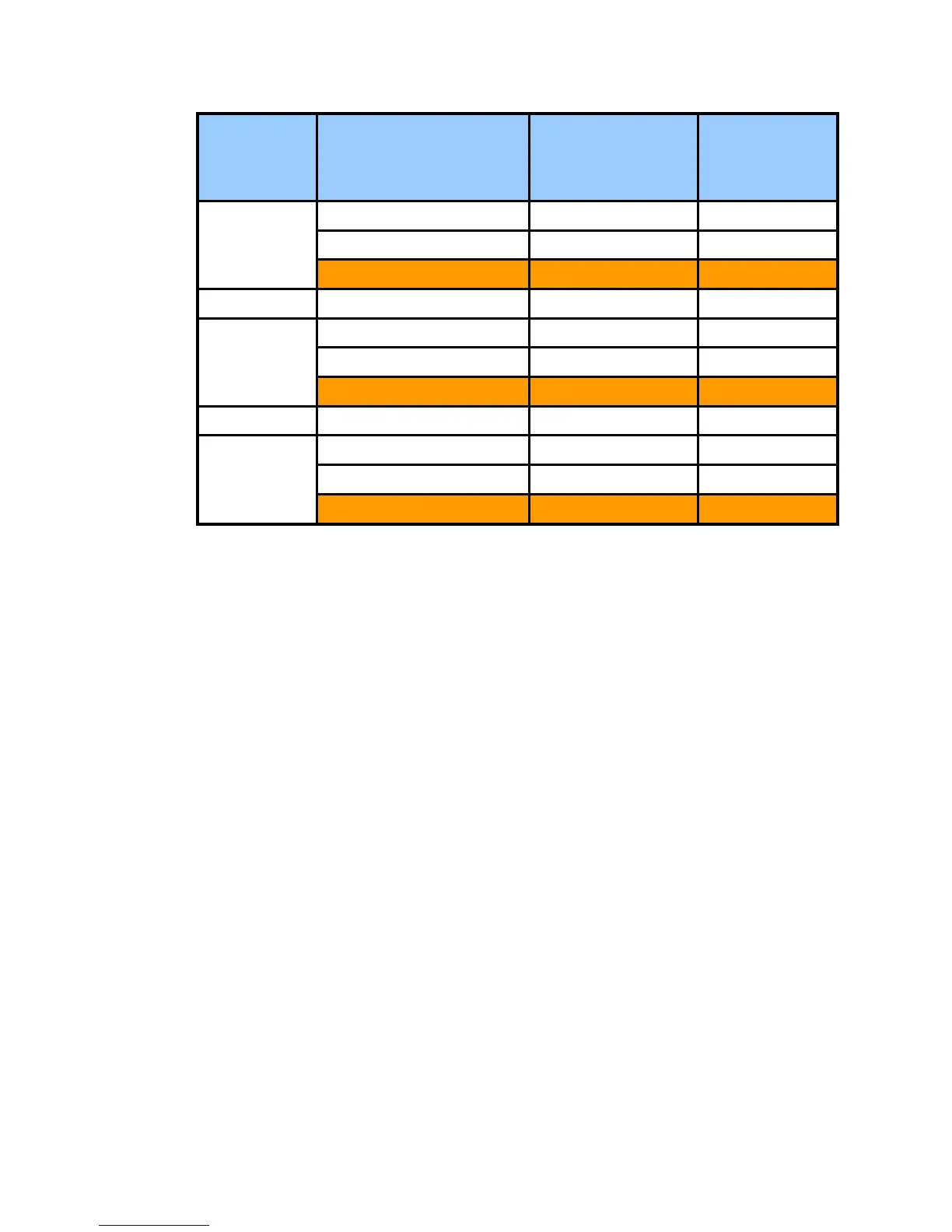

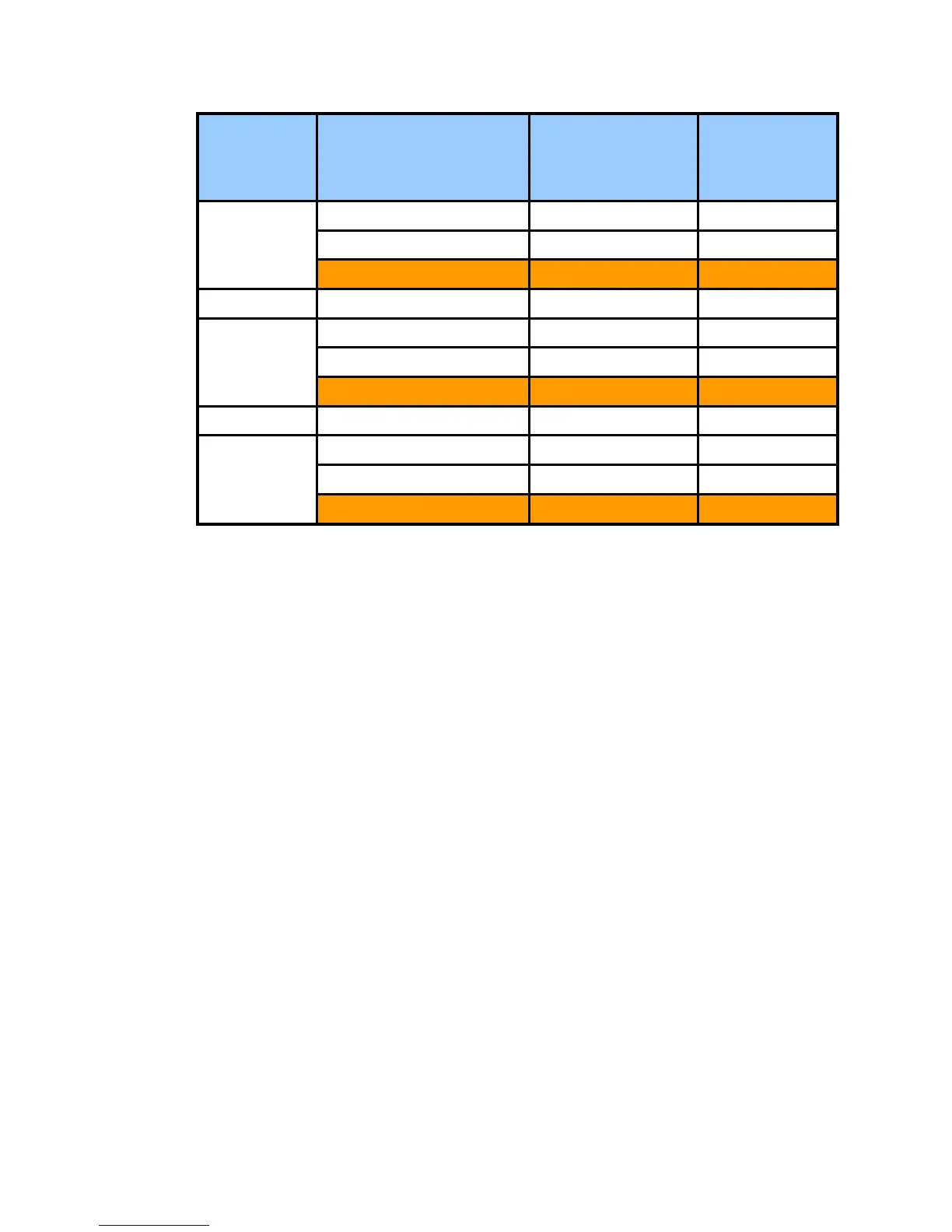

Condenser

Pressure

(Psig)

Suction

Pressure

(Psig)

E2 Store 156 15.3

Non-E2 Store 151 15.5

Diff (E2 vs Non-E2) 5.0 -0.2

E2 Store 125 43.8

Non-E2 Store 122 39.2

Diff (E2 vs Non-E2) 3.0 4.6

E2 Store 129 48.2

Non-E2 Store 122 39.6

Diff (E2 vs Non-E2) 7.0 8.6

Rack A

Rack B

Rack C

Table 5: Summary of key data from field test

• Refrigeration system suction pressures were higher in the E2 store, resulting in

lower refrigeration system energy usage. This was directly attributable to the use

of ESRs and the resulting automatic suction pressure adjustments over the

course of the year and load conditions.

A second similar field test performed in the northeastern US resulted in 17.5%

savings for the ESR/E2 controlled refrigeration systems. Additionally, both test sites with

E2s and ESRs had the benefit of being able to remotely make setpoint changes and

provide optimal evaporator pressure between winter and summer without having a

mechanic adjust the suction pressure. This resulted in not only lower energy

consumption and expense but also lower maintenance expense.

•

CONCLUSIONS

E2 refrigeration controllers are supplied with a full complement of advanced

supermarket refrigeration control algorithms that help cut energy and maintenance

expenses while providing tighter temperature control and higher levels of food quality.

An overall energy saving of 15-30% can be obtained when compared to refrigeration

systems using conventional refrigeration control devices and controllers.

ABOUT THE AUTHOR

Dr. Abtar Singh is Director of Technology at Emerson Retail Services with 10+

years of experience in refrigeration controls & remote monitoring.

Page 14 of 15

Loading...

Loading...