for the meter connections are in accordance with the relevant flange standard. Check the

latest standards for your connections.

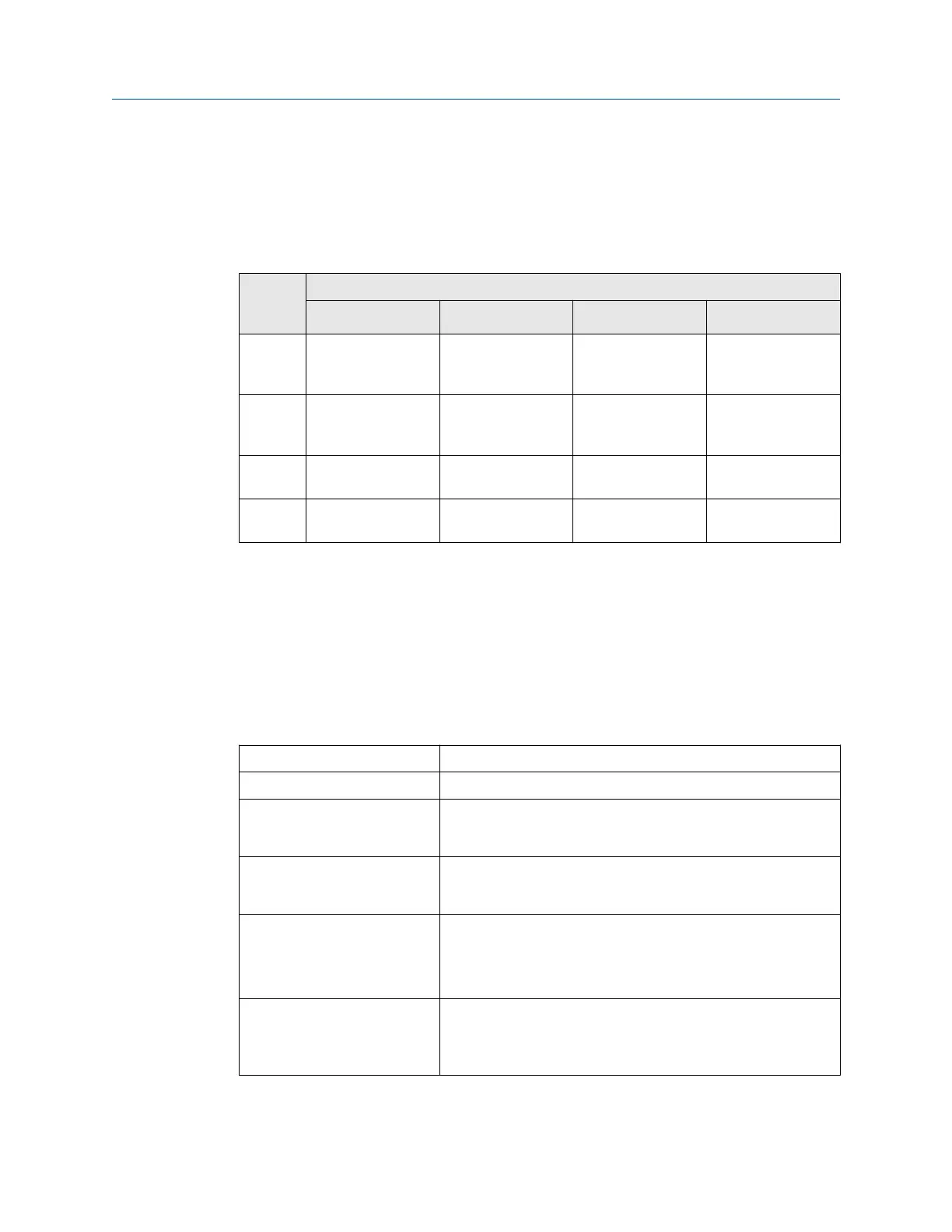

For the pressure and temperature limits for Zirconium 702 process connections, see Table

2-1.

Table 2-1: Pressure/temperature ratings for Zirconium 702 process connections

Process

flange

type

Pressure and temperature ratings

100 °F (37.8 °C) 199.9 °F (93.28 °C) 299.8 °F (148.78 °C) 392 °F (200.0 °C)

2 in

(51 mm)

ANSI 150

226.3 psi

(15.603 bar)

197.3 psi

(13.603 bar)

159.5 psi

(10.997 bar)

110.2 psi

(7.598 bar)

2 in

(51 mm)

ANSI 300

588.9 psi

(40.603 bar)

513.4 psi

(35.398 bar)

417.7 psi

(28.799 bar)

336.5 psi

(23.201 bar)

DN50

PN16

229.2 psi

(15.803 bar)

175.5 psi

(12.100 bar)

137.8 psi

(9.501 bar)

1107.3 psi

(7.398 bar)

DN50

PN40

571.5 psi

(39.404 bar)

439.5 psi

(30.302 bar)

342.3 psi

(23.601 bar)

266.9 psi

(18.402 bar)

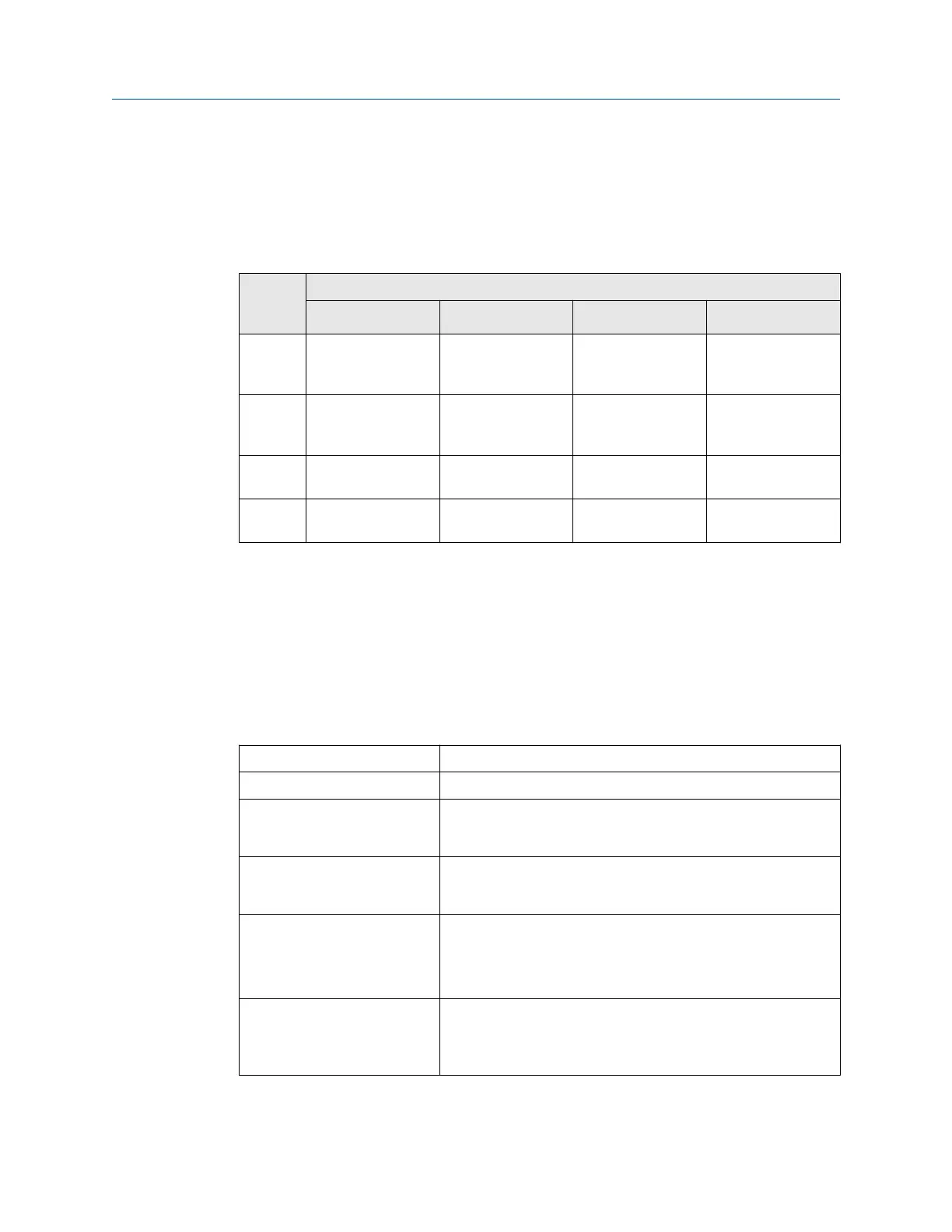

2.5 Recommended installations for short-stem

meters

Micro Motion recommends three standard installations for the short-stem meter to

alleviate any need for onsite calibration. All meters are factory calibrated for these types of

installations and take into consideration the potential boundary effect of each installation.

Free stream applications

Flow rate

0.3 to 0.5 m/s at the meter

Viscosity Up to 20,000 cP

Temperature • -58 °F (-50.0 °C) to 392 °F (200.0 °C)

• -40 °F (-40.0 °C) to 392 °F (200.0 °C) in hazardous areas

Main flow pipe size • Horizontal pipe: minimum diameter, 4 in (102 mm)

• Vertical pipe: minimum diameter, 6 in (152 mm)

Advantages • Simple installation in large bore pipes

• Ideal for clean fluids and non-waxing oils

• Suitable for line density measurement and simple referrals

Recommendations Do not use with:

• Low or unstable flow rates

• For small bore pipes

Planning Installation Manual

May 2019 MMI-20020989

12 Micro Motion Fork Density Meter

Loading...

Loading...