□

Verify that the local ambient and process temperatures are within the limits of the

LNG meters.

□

Verify that you are using low-voltage DC power for the core processor. Excess

voltage can damage the core processor.

□

For I.S. applications, refer to Micro Motion ATEX, UL, or CSA installation instructions.

□

Mount the LNG electronics in any orientation as long as the conduit openings do not

point upward.

CAUTION!

Upward-facing conduit openings risk condensation entering the housing that can

damage the electronics.

□

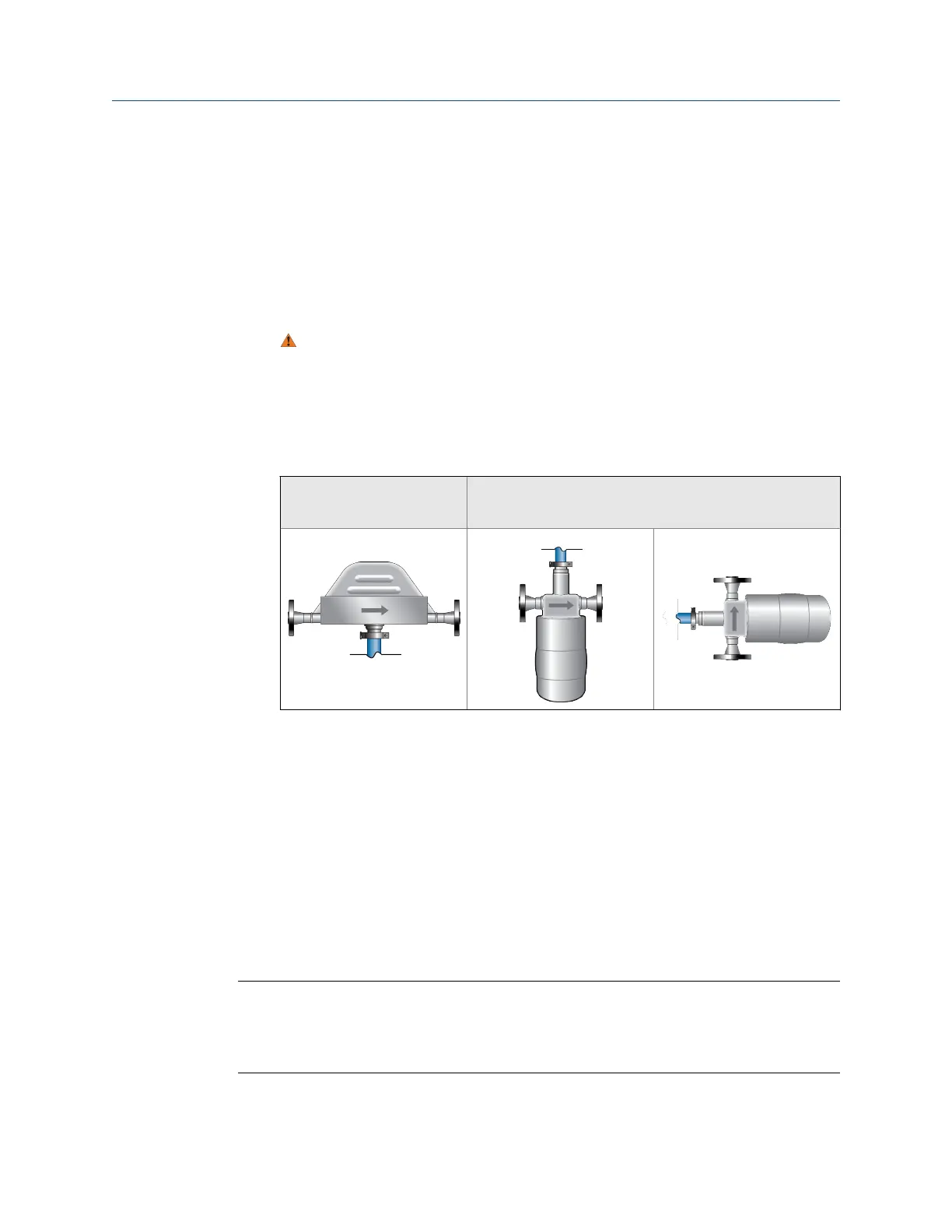

Install the sensors so that the flow direction arrow on the case matches the actual

forward flow of the process. (Flow direction is also software-selectable.)

LNGS06

Gas return sensor

LNGM10

Filling sensor

1.3 Power requirements

•

18 to 30 VDC, 3 watts typical, 5 watts maximum

• Minimum 28 VDC with 300 meters of 1 mm

2

power-supply cable

• At startup, power source must provide a minimum of 0.5 amperes of short term

current at a minimum of 18 volts at the electrical parts power input terminals

• The maximum steady state current is 0.2A

• Complies with Installation (Overvoltage) Category II, Pollution Degree 2

Note

• Power requirements assume a single core processor per cable.

• Length and conductor diameter of the power cable must be sized to provide 18 VDC

minimum at the power terminals, at a load current of 0.2 amps.

Planning

2 Micro Motion Liquified Natural Gas Meter

Loading...

Loading...