Instruction Manual

D103175X012

GX Valve and Actuator

July 2017

24

stretch the seal ring and work it over the top edge of the valve plug. The PTFE material in the seal ring must be

permitted time to cold‐flow during the stretching procedure, so avoid jerking sharply on this ring. Stretching the seal

ring over the valve plug may make it seem unduly loose when in the groove, but it will contract to its original size after

insertion into the bonnet.

2. Install the seat ring, valve plug/stem, bonnet and actuator yoke into the valve body by completing the assembly

according to steps 1 to 3 of the section Assembly of Unbalanced Trim.

Repair Nameplate

If required by the end‐user, an optional repair nameplate is available for recording changes made to the valve trim

during maintenance (see figure 29). This nameplate can be ordered as a spare part, and is easily mounted to the

actuator casing using a casing bolt. (Reference the Parts Ordering section of this manual.)

As shown in figure 29, the repair nameplate provides locations for maintenance personnel to record trim data, such as:

D Date of maintenance

D Trim material

D Port diameter

D Flow capacity (C

v

/ K

v

)

D Flow characteristic

D Actuator Action ATO/ATC

Bellows Maintenance

This section provides instruction on the replacement of the bellows / stem assembly (see key 49 in figure 23).

1. Remove the actuator, bonnet assembly as described in the Replacing Packing section (steps 1 through 10).

2. Remove the plug/stem assemblies as described in the Valve Trim Disassembly section (steps 2 through 6).

3. To install the new bellows / stem assembly (key 49), perform the Valve Trim Assembly (step 3).

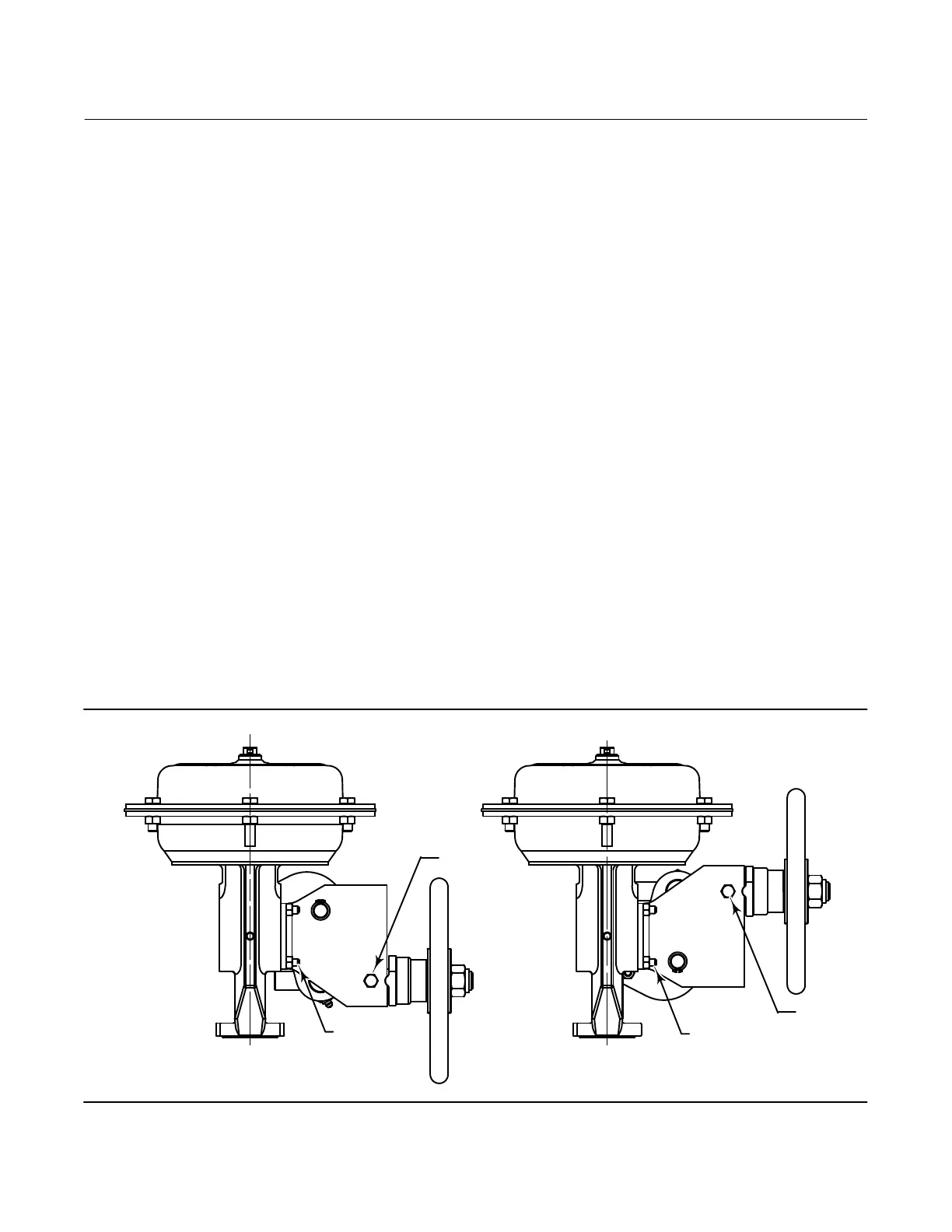

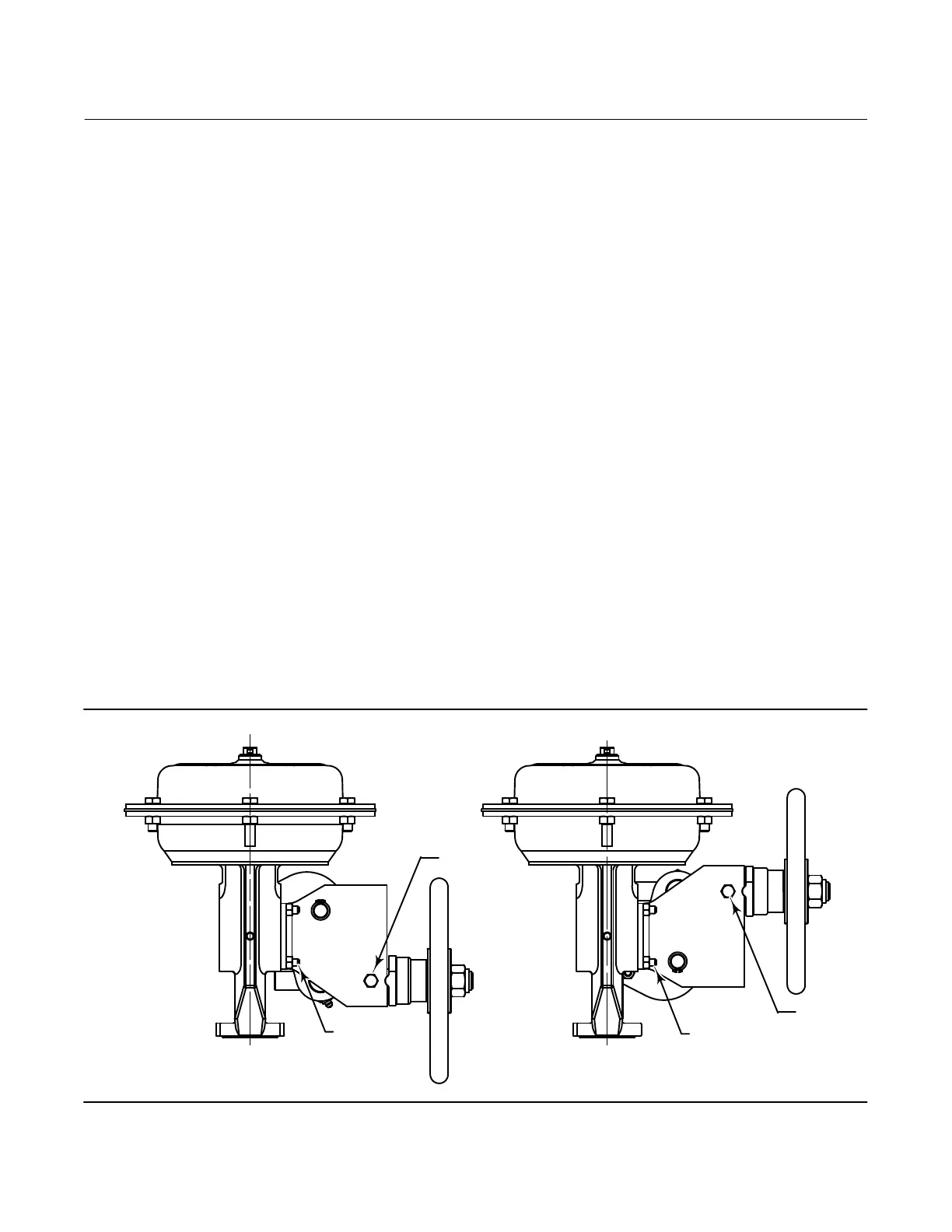

Figure 6. Fisher GX Handwheel Assembly

GE11642‐1

AIR‐TO‐CLOSE, SPRING‐TO‐OPEN

AIR‐TO‐OPEN, SPRING‐TO‐CLOSE

STUD AND

NUT (4)

STUD AND

NUT (4)

LOCKING

SCREW

LOCKING

SCREW

Loading...

Loading...