Instruction Manual

D103175X012

GX Valve and Actuator

July 2017

25

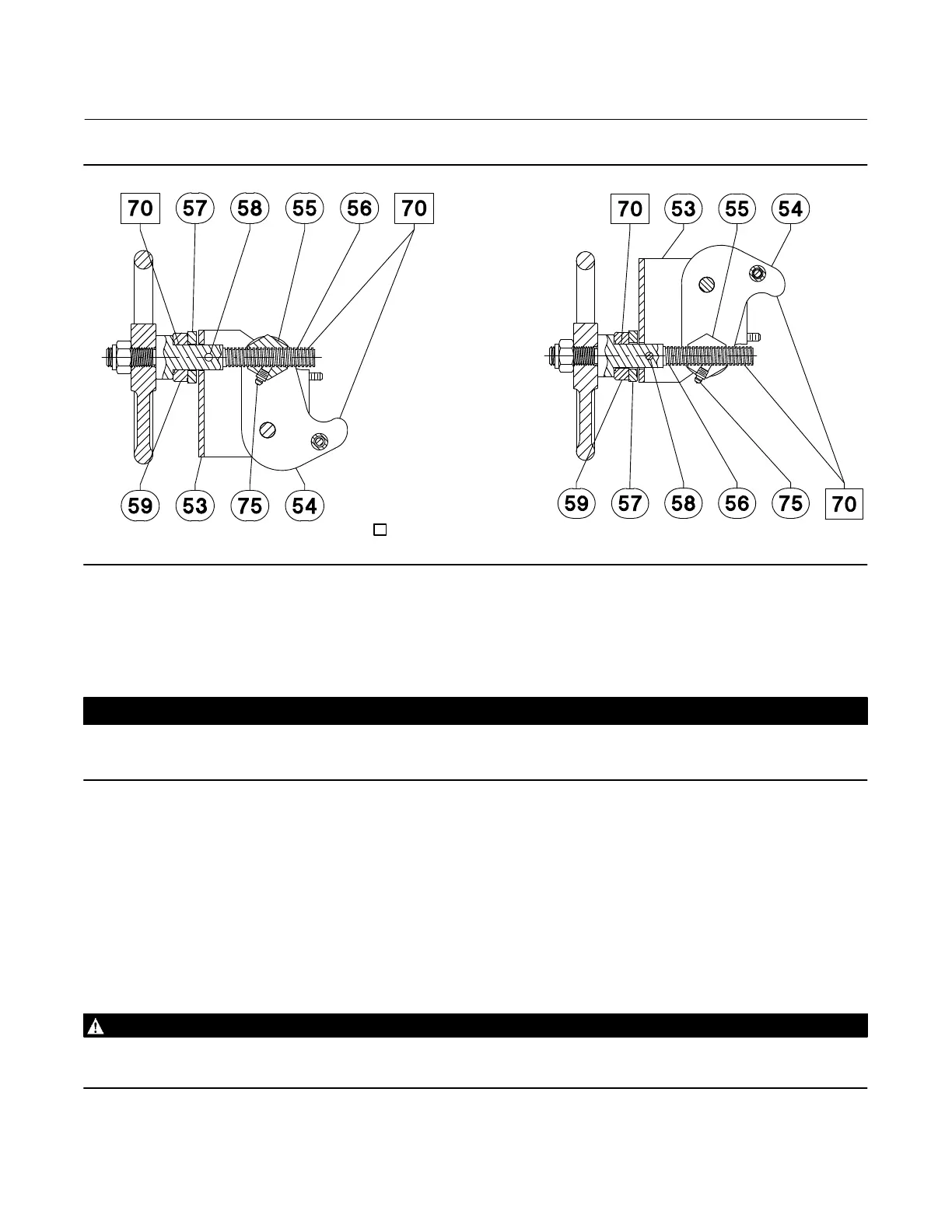

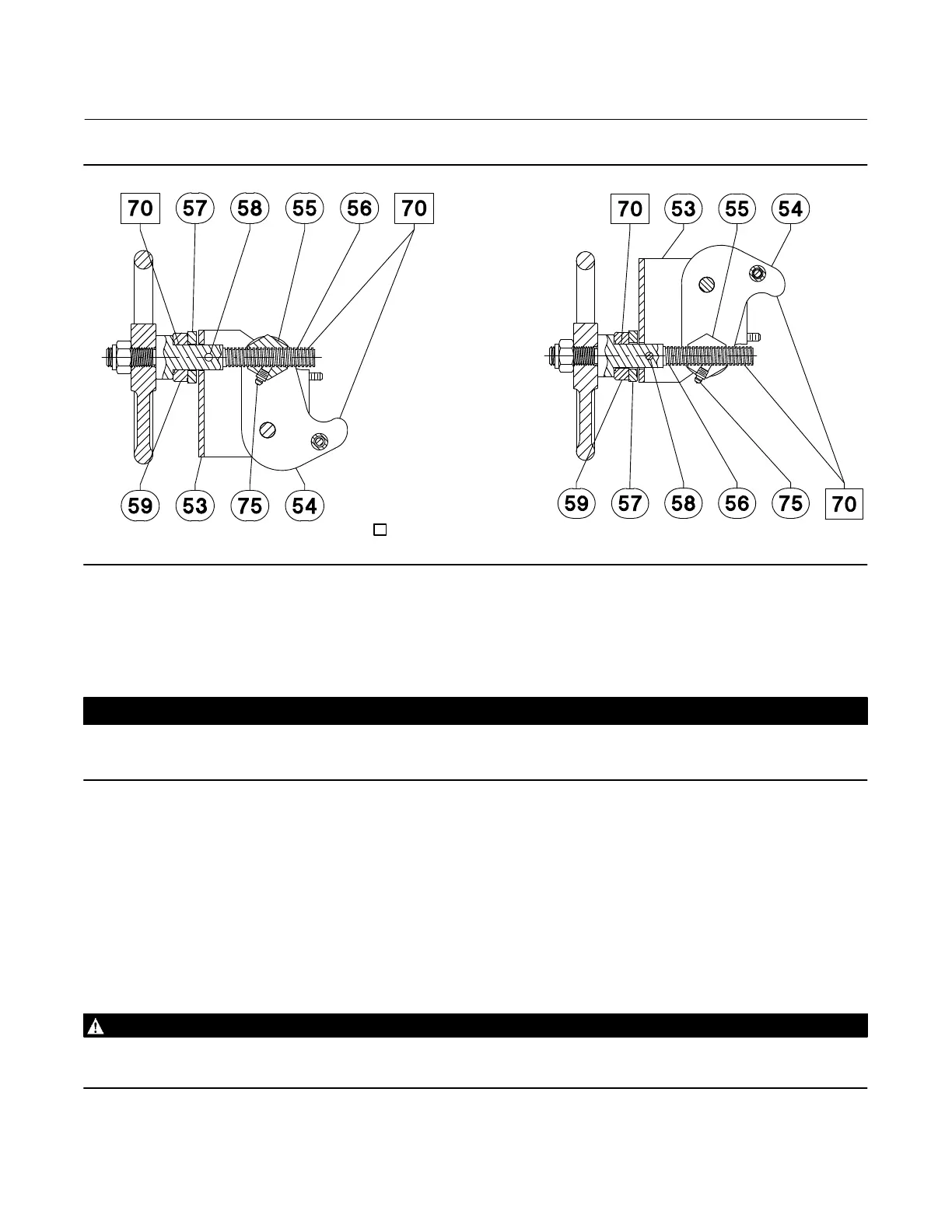

Figure 7. Fisher GX Handwheel Orientation and Grease Zerk Location

AIR‐TO‐CLOSE, SPRING‐TO‐OPENAIR‐TO‐OPEN, SPRING‐TO‐CLOSE

GE05809‐D

GE05810‐D

APPLY LUBRICANT

Handwheel Operation

CAUTION

This handwheel is designed only for use with size 225 and 750 actuators with 20 mm travel. To avoid equipment damage,

do not assemble this handwheel on size 750 actuators with 40 mm travel or size 1200 actuators.

Principle of Operation

The GX handwheel is designed to compress the actuator springs and override the actuator fail action. Turning the

handwheel drives the screw, nut, and levers. The levers push against the stem connector to transfer this motion.

Reversing the direction of the handwheel will move the nut and levers in the opposite direction. Once the levers are no

longer in contact with the stem connector, the locking screw should be used to secure the handwheel against

undesired movement. To prevent damage due to overtravel, the handwheel should not be turned more than 2 full

turns past the point at which the levers no longer contact the stem connector.

WARNING

To avoid personal injury or loss of process control due to equipment damage, ensure the levers are completely disengaged

and the locking screw is tight while the valve is in normal pneumatic operation.

Loading...

Loading...