satisfactory, but the valves are leak-

ing.

If

the

compre

ssion has increased

10 pounds

or

more over the original

re

ading, there is leakage past the

rings.

During a compression test,

if

the

pressure fails to climb steadily

and

remains the same during the first two

successive strokes,

but

climbs higher

on the succeeding strokes,

or

fails to

climb during the entire test, it indi-

cates a sticking valve.

VALVE LASH

COLD VALVE LASH

If

the valve

rocker

arm

s

haft

as-

se

mbly has been removed and in-

stalled, it will be necessary

to

make

a

preliminary (cold) valve lash adjust-

ment before starting the engine.

If

tbe adjustment

is

made for

an

engine

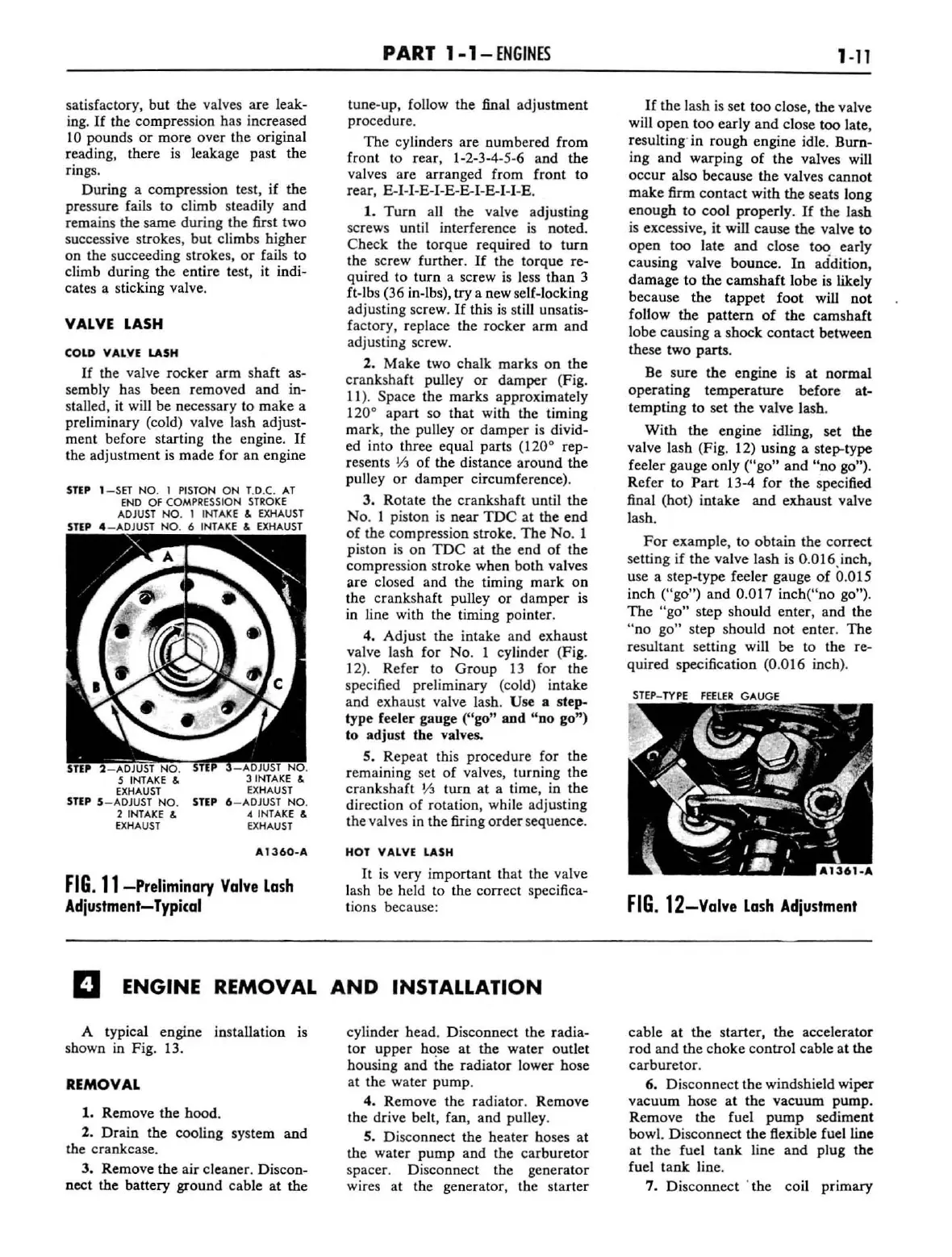

STEP

l -

SET

NO. I

PISTON

ON T,D.

C.

AT

END

OF

COMPRESSION

STROKE

ADJUST

NO

. 1 INTAKE & EXHAUST

4

-ADJ

UST

NO

. 6 INTAKE & EXHAUST

.s

INTAKE &

EXHAUST

SliP

S- ADJUST

NO

.

2 INTAKE &

EXHAUST

3 INTAKE &

EXHAUST

SliP

6 - ADJUST

NO

.

.. IN

TAKE

&

EXHAUST

A

1360-A

FIG.

II-Preliminary

Valve

lash

Adjustment-Typical

PART

1-1-

ENGINES

tune-up, follow the final adjustment

procedure.

The

cylinders are numbered from

front to rear, 1-2-3-4-5-6 and the

valves are arranged from front

to

rear, E-I-I-E-I-E-E-I-E-I-I-E.

1.

Turn

a

ll

the valve adjusting

screws until interference

is

noted.

Check the torque required

to

turn

the screw

further

.

If

the torque re-

quired to

turn

a screw is less

than

3

ft-Ibs (36 in-Ibs),

try a new self-locking

adjusting screw.

If

this

is

still unsatis-

factory, replace the rocker

arm

and

adjusting screw.

2. Make two chalk marks

on

the

crankshaft

pulley

or

damper

(Fig.

11).

Space the

mark

s approximately

120

0

a

part

so

that

with the timing

mark, the pulley

or

damper

is divid-

ed into three equal parts (120

0

rep-

resents

VJ

of

the distance

around

the

pulley

or

damper

circumference).

3. Rotate the crankshaft until

the

No

. 1 piston

is

near

TDe

at

the

end

of

the compression stroke.

The

No.1

pis

ton

is

on

TDC

at the end

of

the

compre

ss

ion stroke when both valves

are

closed

and

the timing

mark

on

the

crankshaft

pulley

or

damper

is

in line with the timing pointer.

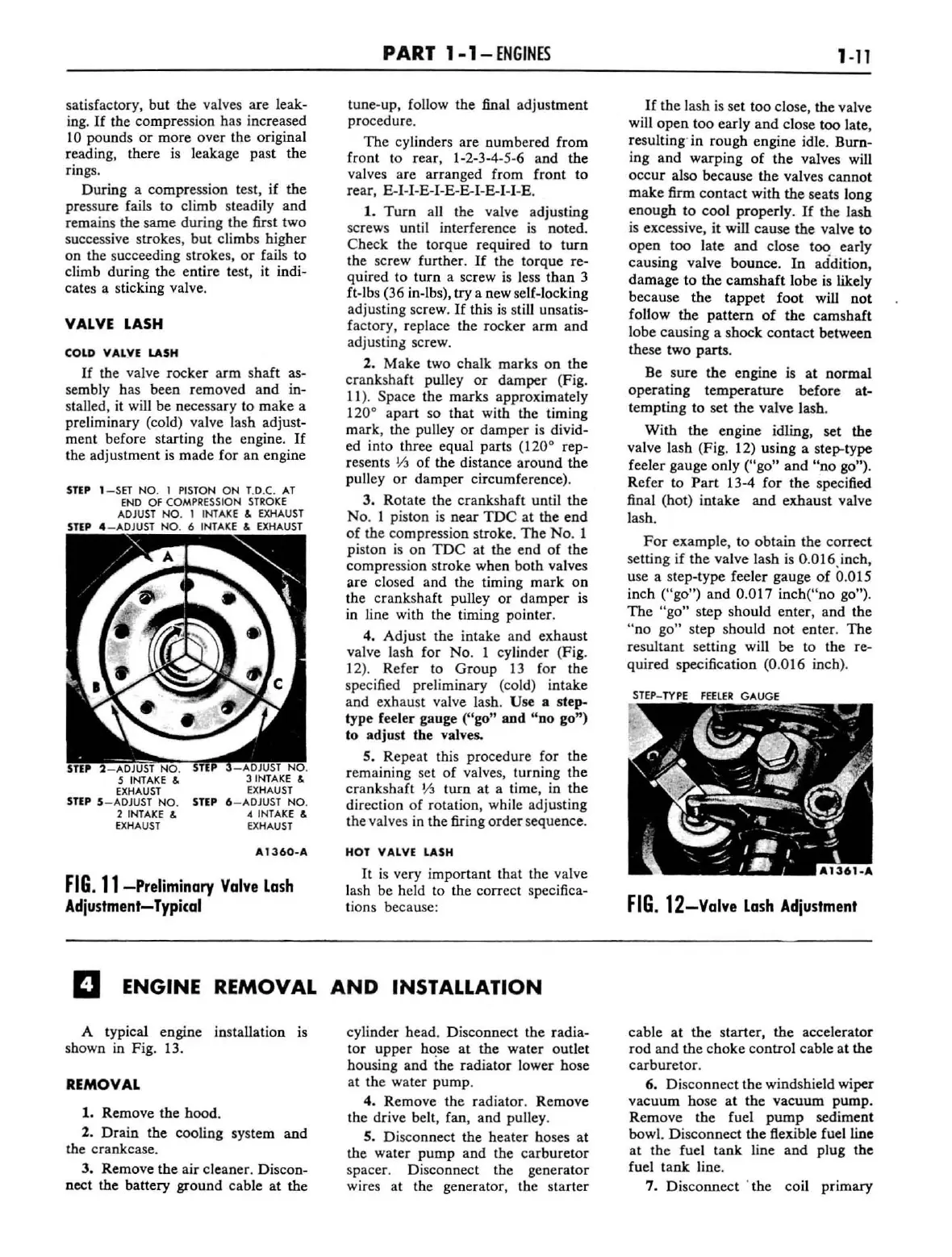

4. Adjust the intake and exhaust

valve lash for No. 1 cylind

er

(Fig.

12). Refer

to

Group

13

for the

specified preliminary (cold) intake

and

exhaust valve lash. Use a step-

type feeler gauge

("go"

and

"

00

go")

to

adjust the valves.

S. Repeat this procedure

for

the

remaining set

of

valves, turning the

crankshaft

VJ

turn

at a time, in

the

direction

of

rotation, while adjusting

the valves in the firing

order

sequence.

HOT

VALVE

LASH

It

is very important that the valve

lash be held

to

the correct specifica-

tions because:

D ENGINE REMOVAL

AND

INSTALLATION

A typical engine installation is

shown in Fig. 13.

REMOVAL

1. Remove the hood.

2.

Dr

ain the cooling system

and

the crankcase.

J. Remove the air cleaner. Discon-

nect the battery ground cable at the

cylinder head. Disconnect the radia-

tor

upper

ho:se

at

the

water outlet

housing

and

the

radiator

lower hose

at the water pump.

4. Remove the radiator. Remove

the drive belt, fan,

and

pulley.

s.

Disconnect the heater

ho

ses at

the water

pump

and the

carburetor

spacer. Disconnect the generator

wires at the generator, the start

er

1-11

If

the lash

is

set too close, the valve

will

open

too

early

and

close too late,

resulting' in rough engine idle. Burn-

ing and warping

of

the

valves will

occur

also because the valves

cannot

make

firm

contact

with

the

seats long

enough

to

cool

properly.

If

the lash

is

excessive,

it

will cause

the

valve

to

open

too

late

and

close too early

causing valve bounce.

In

addition,

damage

to

the

camshaft

lobe is likely

because

the

tappet

foot

wiU

not

follow

the

pattern

of

the

camsbaft

lobe causing a shock

contact

between

these two

parts.

Be sure

the

engine is

at

normal

operating

temperature

before

at-

tempting

to

set the valve lash.

With the engine idling, set the

valve lash (Fig. 12) using a step-type

feeler gauge only

("go"

and

"no

go").

Refer

to

Part

13-4 for

the

specified

final (hot)

intake

and

exhaust valve

lash.

For

example,

to

obtain

the

cor

rect

setting if

the

valve lash

is

O.

016)nch.

use a step-type feeler gauge

of

0.

015

inch

("go")

and

0.017

inch("no

go").

The

"go"

step

shou

ld enter, and the

"no

go" step should

not

enter.

The

resultant setting will be

to

the re-

quired

specification (0.016 inch).

FIG.

12-Valve lash

Adjustment

cable

at

the

starter, the accelerator

rod

and

the

choke

control

cable at the

carburetor

.

6.

Disconnect

the windshield wiper

vacuum

hose

at

the

vacuum

pump.

Remove the fuel

pump

sediment

bowl.

Disconnect

the

flexible fuel line

at the fuel

tank

line

and

plug the

fuel

tank

line.

7.

Disconnect

' the coil primary

Loading...

Loading...