4. Insert the upper bearing re-

moval tool (tool 6331) in the oil hole

in the crankshaft.

5. Rotate the crankshaft in the di-

rection

of

engine rotation

to

force the

bearing

out

of

th

e block.

6. Clean the crankshaft journal.

When

replacing

standard

bearings

with new bearings, it is good practice

to first

try

to

obtain

the

proper

clear-

ance

with two

blue

bearing

halves.

7.

To

install the

upper

main bear-

ing, place the plain end

of

the bearing

over the

shaft

on the locking tang

side

of

the block. Using tool 6331 in

the oil hole in the

crankshaft,

rotate

the

crankshaft

in

the

opposite direc-

tion

of

engine rotation until the bear-

ing seats itself. Remove the tool.

8. Replace

the

cap

bearing.

9. Support the

crankshaft

so

that

its weigbt will

not

compress the Plas-

ligage

and

provide

an

erroneous

reading.

Position a jack so

that

it will

bear against the counterweight

ad-

joining the bearing which

is

being

checked.

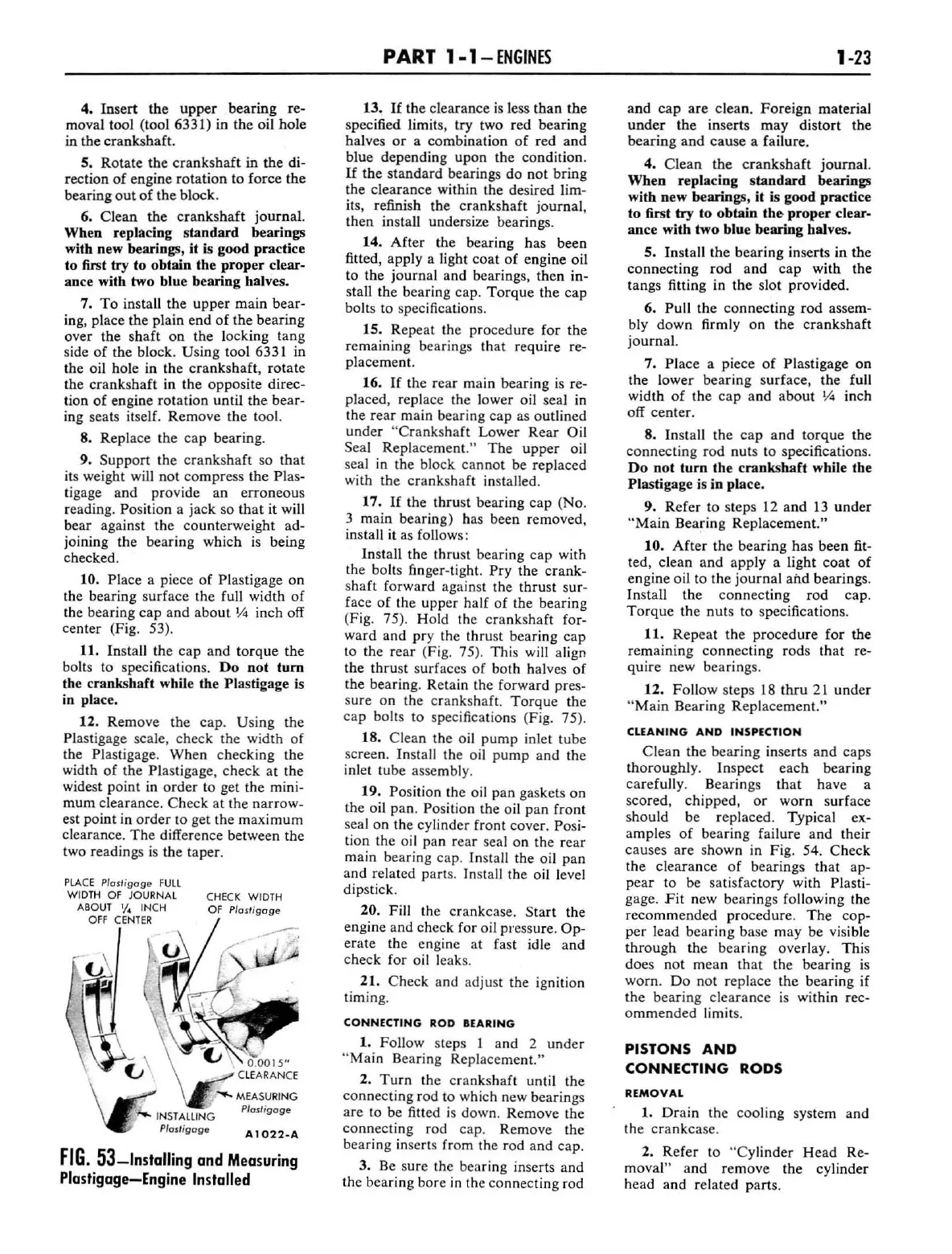

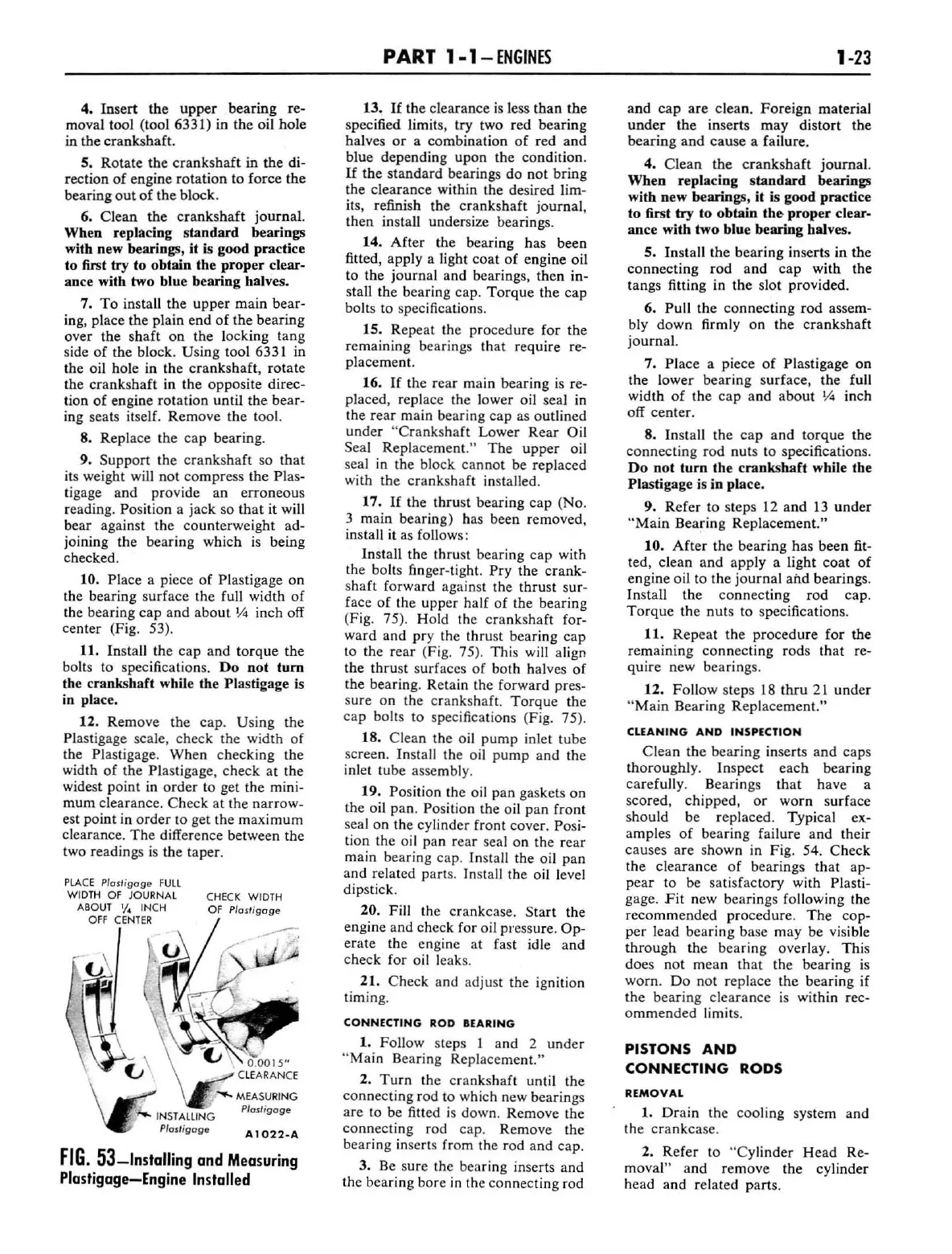

10. Place a piece

of

Plastigage on

the bearing surface the fu

ll

width

of

the bearing cap

and

about

JA

inch off

center (Fig. 53).

11. Install the cap

and

torque

the

bolts to specifications.

Do

not

tum

the crankshaft while the Plastigage is

in place.

12. Remove the cap. Using the

Plastigage scale, check

th

e width

of

the Plastigage.

When

checking the

width

of

the Plastigage, check at the

widest point in

order

to get the mini-

mum clearance. Check at the narrow-

est point in

order

to

get the

maximum

clearance.

The

difference between the

two readings

is

the taper.

PLA

CE

Plo

sl"

go

ge

FULL

WI

DTH

OF

JOURNAL

A80UT

1/4

INCH

OFF

C

ENTER

C

HE

CK WIDTH

OF

Plosligoge

P/osli

goge

P/o

st

igog

e

A 1

022-A

FIG.

53-Installing

and Measuring

Plastigage-Engine

Installed

PART

1-1-

ENGINES

13.

If

th

e clearance

is

less

than

the

specified limits, try two red bearing

halves

or

a combination

of

r

ed

and

blue depending upon the condition.

If

tbe

standard

bearings do not bring

the clearance with

in

the desired lim-

its, refinish the crankshaft

journa

l,

then install undersize bearings.

14.

After

the bearing has been

fitted, apply a light

coat

of

engine oil

to the journal and bearings, then

in-

sta

ll

the bearing cap.

Torque

the cap

bolts to specifications.

15. Repeat the procedure for the

remaining bearings

that

require re-

placement.

16.

If

the rear main bearing

is

re-

placed, replace the lower oil seal

in

the rear ma

in

bearing

cap

as outlined

under

"

Crank

s

haft

Lower Rear Oil

Se

al Repla

cement."

The

upper

oil

seal

in

the block

cannot

be replaced

with the

crankshaft

in

stalled.

17.

If

the thrust bearing

cap

(No.

3 main bearing) has been removed,

install it as follows:

Install the thrust bearing

cap

with

the bolts finger-tight.

Pry

the

crank-

shaft forward against the thrust sur-

face

of

the upper

half

of

the bearing

(Fig. 75). Hold the crankshaft

for-

ward and pry the thrust bearing cap

to the rear (Fig. 75). This will a

li

gn

the thrust surfaces

of

both halves

of

the bearing. Retain the forward pres-

sure on the crankshaft.

Torque

the

cap bolts to spec

ific

ations (Fig. 75).

18. Clean the oil

pump

in

l

et

tube

screen.

In

stall the oil

pump

and

the

inlet tube assembl

y.

19.

Po

sition the

oi

l pan gaskets on

the o

il

pan. Position the oil pan front

seal on the cylin

der

front cover. Posi-

tion the oil pan rear seal on the rear

main bearing ca

p.

Install the oil pan

and related part

s.

Install the oil level

dipstick.

20. Fi

ll

the crankcase.

Start

the

engine and check for oil pressure.

Op-

erate the eng

in

e

at

fast idle

and

check for oil

le

ak

s.

21. Check and adjust the ignition

timing.

CONNECTING

ROD BEARING

1. Follow steps I and 2

under

"Ma

in

Bearing Replacement."

2.

Turn

the crankshaft until the

connecting rod to which new bearings

are to be fitted is down. Remove the

connect

in

g rod ca

p.

Remove the

beari

ng

in

serts from the rod and cap.

3. Be sure the bearing inserts

and

the bearing bore

in

the connecting rod

1-23

and

cap

are clean.

Foreign

material

under

the

inserts m

ay

distort the

bearing

and

ca

use a failure.

4. Clean the

crankshaft

journal.

When

replacing

sta

ndard

bearings

with new bearings,

it

is good practice

to

first

try

to

obtain

the

proper

clear·

ance

with

two

blue bearing halves.

5.

In

stall the bearing inserts in the

co

nnecting rod

and

cap

with the

tangs fitting in the slot provided.

6.

Pull the connecting rod assem-

bly

down

firmly

on

the

cra

nkshaft

journal.

7.

Place a piece

of

Plastigage on

the l

ower

bearing surface, the full

width

of

the

cap

and

abou

t

Y<a

inch

off center.

8.

In

stall the

cap

and

torque

the

connecting rod nuts

to

specifications.

Do

not

turn

the

crankshaft

while the

Plastigage is in place.

9. Refer to steps

12

and

13

under

"Main

Bearing Replacement."

10.

After

the bearing has been fit-

ted, clean

and

apply a light coat

of

engine oil to the journal

and

bearings.

In

sta

ll

the

connec

ting rod cap.

Torque

the nuts to specifica

ti

ons.

11.

Repeat

the

procedure

for the

remaining connecting rods that

re-

quire new bearings.

12. Follow steps

18

thru

21

under

"

Main

Bearing Replacement."

CLEANING

AND

INSPECTION

Clean

the bearing inserts

and

caps

thoroughly.

In

spect each bearing

carefu

ll

y. Bearings

that

have a

scored, chipped,

or

worn

surface

should be replaced. Typical

ex-

amples

of

bearing failure and their

causes are shown

in

Fig. 54. Check

the cl

earance

of

bearings

that

ap-

pear

to

be satisfactory with Plasti-

gage. F it new bearings following the

recommended

procedure.

The

cop-

per

lead bearing base

may

be visible

through

the bearing overlay. This

does not mean

that

the bearing

is

worn.

Do

not replace the bearing if

the bearing clearance

is

wi

thin rec-

ommended

limit

s.

PISTONS AND

CONNECTING RODS

REMOVAL

1.

Drain

the

coo

ling system and

the

crankca

se.

2. Refer to

"Cylinder

Head

Re-

moval" and remove

th

e cylinder

head and related parts.

Loading...

Loading...