l-06

Basic Engine

I-06

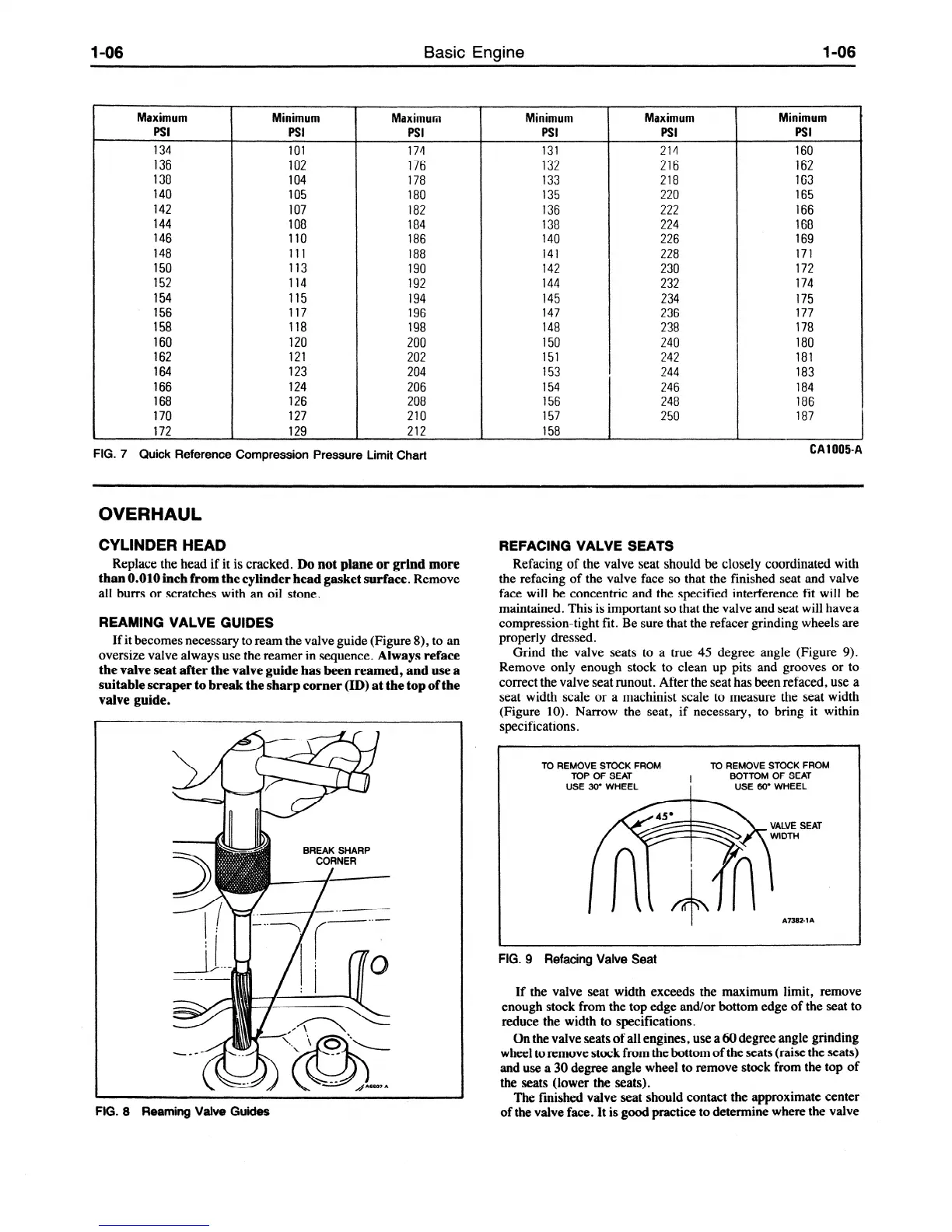

Maximum

PSI

I

Minimum

PSI

~~~ T

Maximum

PSI

134

101

174

131

136

102

176

132

138

104 178 133

140

105 180 135

142

107

182

136

144

108

184 138

146 110

186 140

148 111

188

141

150 113

190

142

152 114

192 144

154

115

194 145

156

117

196

147

158 118 198 148

160 120

200 150

162

121

202 151

164 123 204 153

166

124

206

154

168 126 208 156

170

127

210

157

172 129 212 158

Minimum

PSI

I

Maximum

PSI

214

216

218

220

222

224

226

228

230

232

234

236

238

240

242

244

246

248

250

Minimum

PSI

160

162

163

165

166

168

169

171

172

174

175

177

178

180

181

183

184

186

187

FIG.

7

Quick Reference Compression Pressure Limit Chart

CA1

005-A

OVERHAUL

CYLINDER HEAD

Replace the head if it is cracked.

Do not plane or grind more

than 0.010 inch from the cylinder head gasket surface.

Remove

all burrs or scratches with an oil stone.

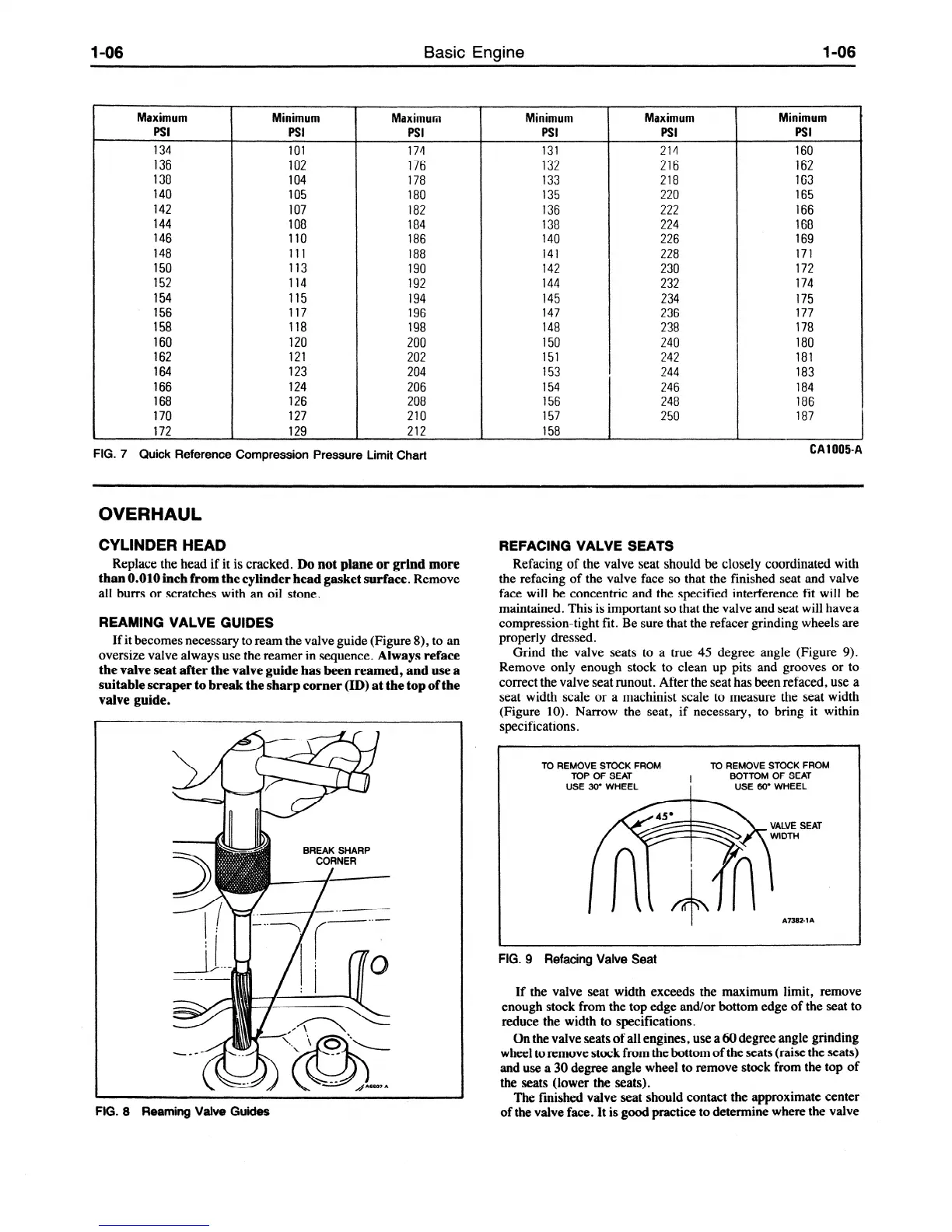

REAMING VALVE GUIDES

If it becomes necessary to ream the valve guide (Figure 8)) to an

oversize valve always use the reamer in sequence.

Always reface

the valve seat after the valve guide has been reamed, and use a

suitable scraper to break the sharp corner (ID) at the top of the

valve guide.

BREAKSHARP

FIG. 8

Reaming Valve Guides

REFACING VALVE SEATS

Refacing of the valve seat should be closely coordinated with

the refacing of the valve face so that the finished seat and valve

face will be concentric and the specified interference fit will be

maintained. This is important so that the valve and seat will have a

compression-tight fit. Be sure that the refacer grinding wheels are

properly dressed.

Grind the valve seats to a true 45 degree angle (Figure 9).

Remove only enough stock to clean up pits and grooves or to

correct the valve seat runout. After the seat has been refaced, use a

seat width scale or a machinist scale to measure the seat width

(Figure 10). Narrow the seat, if necessary, to bring it within

snecifications.

TO REMOVE STOCK FROM TO REMOVE STOCK FROM

TOP OF SEAT

I

BOTTOM OF SEAT

USE 30” WHEEL

I

USE 60” WHEEL

A7382-1 A

FIG. 9 Refacing

Valve

Seat

If the valve seat width exceeds the maximum limit, remove

enough stock from the top edge and/or bottom edge of the seat to

reduce the width to specifications.

On the

valve seats

of all

engines,

use a 60 degree angle grinding

wheel

to remove stock from the

bottom of the seats (raise the seats)

and use a 30 degree angle

wheel

to remove stock from the top of

the seats (lower

the seats).

The finished valve seat should

contact the approximate center

of the valve face. It is good practice to determine where the valve

Loading...

Loading...