02-3

lanition Svstem - Distributorless

02-3

DESCRIPTION AND OPERATION

WARNING

. HIGH VOLTAGE PRODUCED BY A

DISTRIBUTORLESS IGNITION SYSTEM IS HIGHER

THAN FOR A CONVENTIONAL IGNITION SYSTEM.

. WHEN CARRYING OUT SERVICE OPERATIONS ON

AN ENGINE EQUIPPED WITH DISTRIBUTORLESS

IGNITION, IT IS IMPORTANT TO BE AWARE OF THE

ABOVE POINT AS WELL AS ALL THE USUAL

SAFETY MEASURES TO PREVENT THE

POSSIBILITY OF ELECTRIC SHOCKS.

The purpose of an engine’s ignition system is to ignite the

fuel/air mixture at the correct time and sequence based

upon the input it receives.

The Distributorless Ignition System (DIS) used on the VSG

411/413 engines is a state-of-the-art ignition system. The

brain of this system is the Ignition Control Module (ICM),

also known as the Universal Electronic Spark Control

(UESC) module. This module normally receives four

inputs:

From these inputs, the ICM computes spark strategy

(spark advance) to obtain optimum engine performance for

correct input conditions.

With this system, the electronic control module monitors

the engine load, speed, and operating temperature and

was on exhaust will be on compression, and the one that

decides what degree of spark advance is correct for all of

the operating conditions. This system maximizes the

was on compression will be on exhaust. The spark in the

benefits of the high compression swirl design. Because

timing is set for life inherently in the design of the engine,

exhaust cylinder is wasted but little of the coil energy is lost.

and there are no moving parts in the ignition system itself,

no maintenance is required except for periodic spark-plug

The spark strategy is based on sensors and manifold

checks. The system provides for fixed spark advance at

vacuum input to the ICM module, which include the

start-up, for cold weather starting, fixed advance for

service checking, and for “average value” default settings

in case of component failure. Particular attention has been

given to spark optimization for excellent fuel economy in

the warm-up mode, which is coupled with improved

warm-up and a new carburetor.

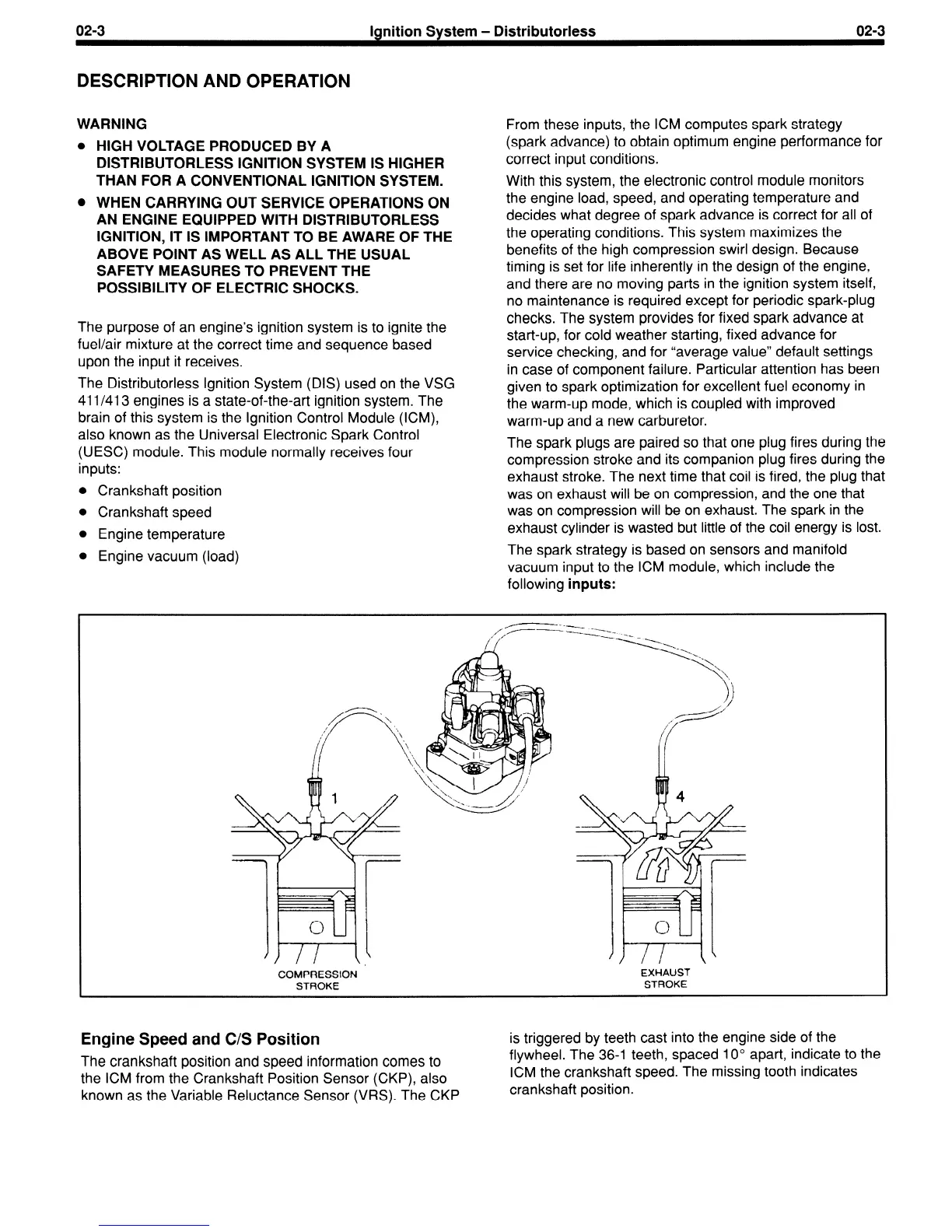

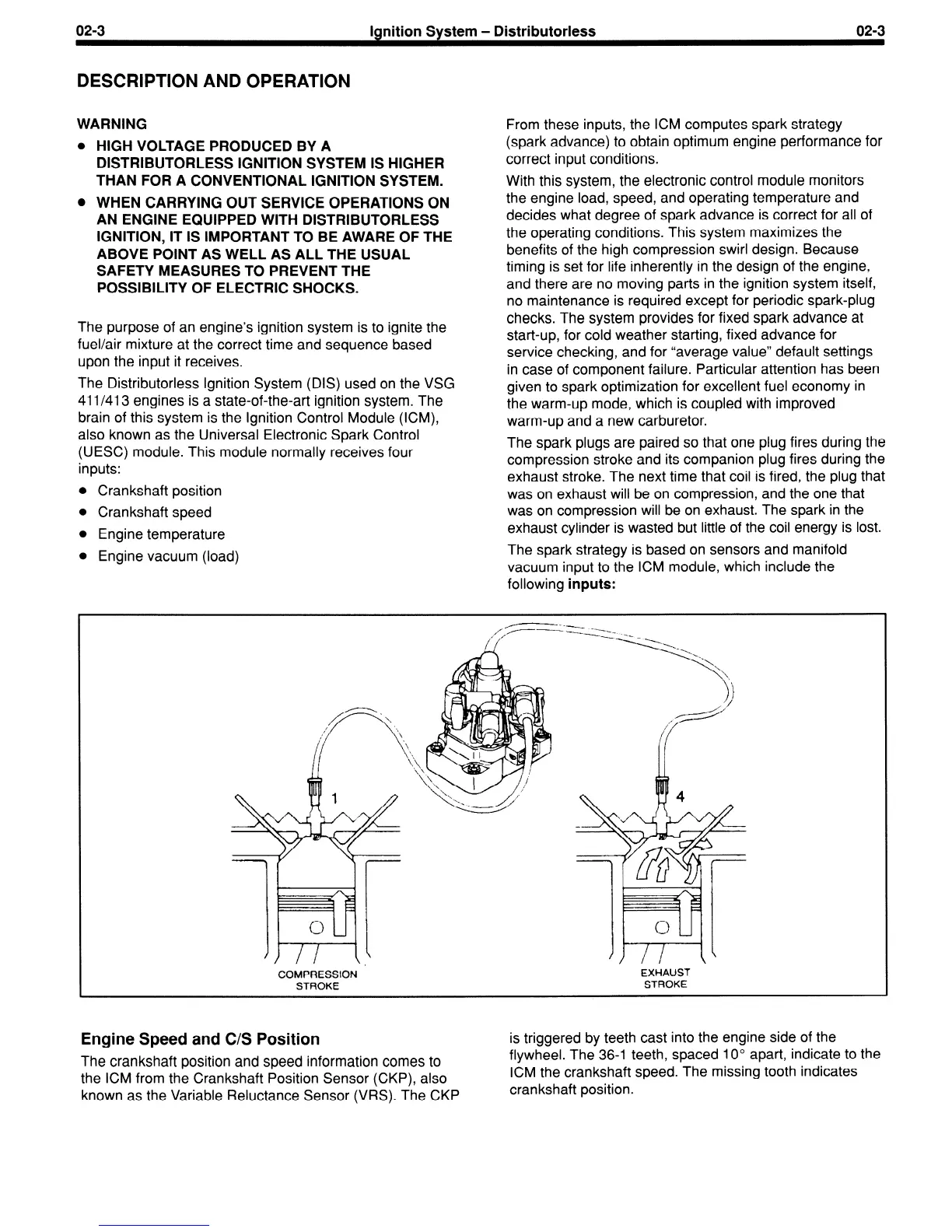

The spark plugs are paired so that one plug fires during the

compression stroke and its companion plug fires during the

exhaust stroke. The next time that coil is fired, the plug that

l

Crankshaft position

l

Crankshaft speed

l

Engine temperature

l

Engine vacuum (load)

following

inputs:

COMPRESSION

EXHAUST

STROKE

STROKE

Engine Speed and C/S Position

The crankshaft position and speed information comes to

the ICM from the Crankshaft Position Sensor (CKP), also

known as the Variable Reluctance Sensor (VRS). The CKP

is triggered by teeth cast into the engine side of the

flywheel. The 36-1 teeth, spaced IO” apart, indicate to the

ICM the crankshaft speed. The missing tooth indicates

crankshaft position.

Loading...

Loading...