01-16

Basic Engine

01-16

CLEANING AND INSPECTION (Continued)

Pistons, Pins and Rings

Main and Connecting Rod Bearings

Cleaning

Cleaning

Remove deposits from the piston surfaces. Clean gum or

varnish from the piston skirt, piston pins and rings with

solvent.

Do not use a caustic cleaning solution or a wire

brush to clean pistons.

Clean the bearing inserts and caps thoroughly in solvent,

and dry them with compressed air.

Do not scrape gum or

varnish deposits from the bearing shells.

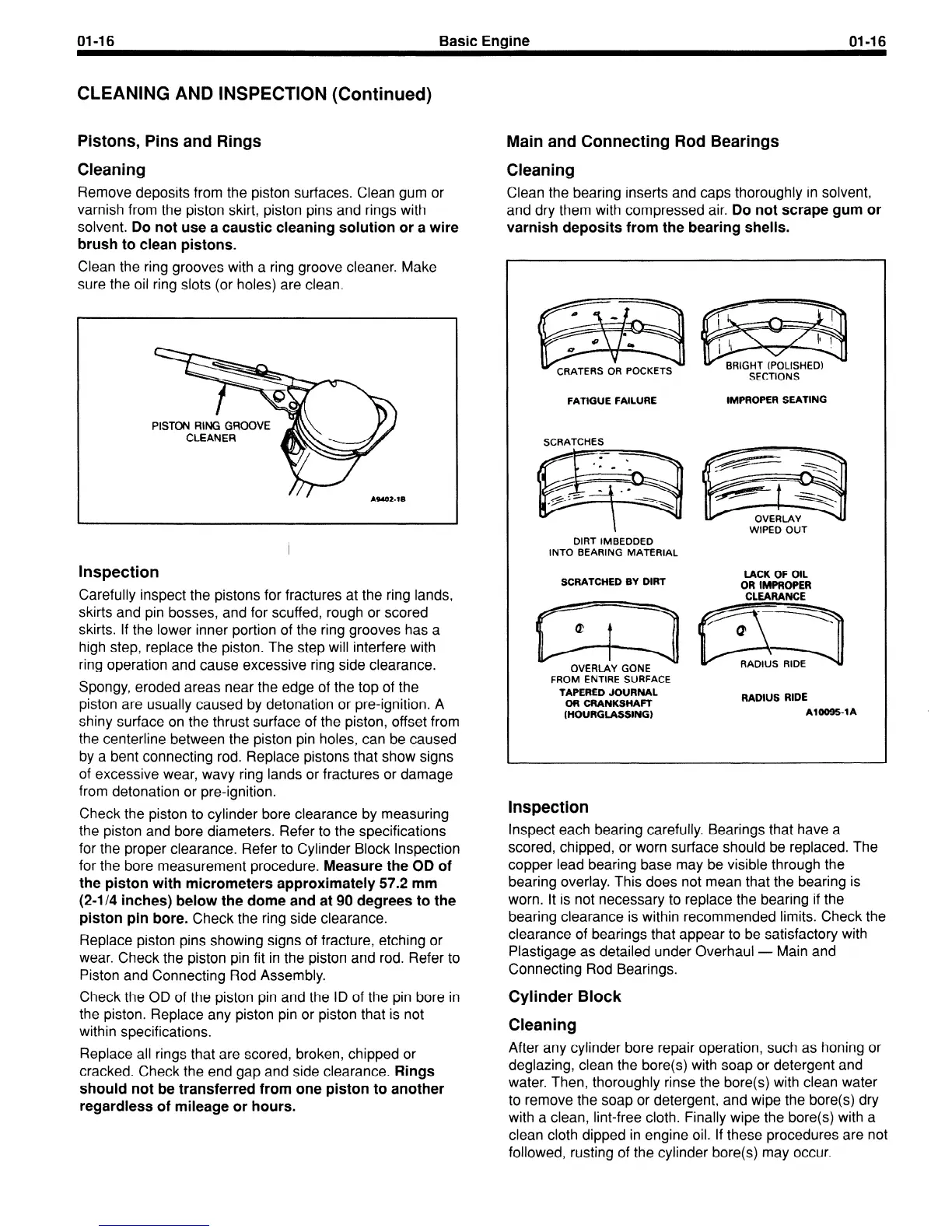

Clean the ring grooves with a ring groove cleaner. Make

sure the oil ring slots (or holes) are clean.

CLEANER

Inspection

Carefully inspect the pistons for fractures at the ring lands,

skirts and pin bosses, and for scuffed, rough or scored

skirts. If the lower inner portion of the ring grooves has a

high step, replace the piston. The step will interfere with

ring operation and cause excessive ring side clearance.

Spongy, eroded areas near the edge of the top of the

piston are usually caused by detonation or pre-ignition. A

shiny surface on the thrust surface of the piston, offset from

the centerline between the piston pin holes, can be caused

by a bent connecting rod. Replace pistons that show signs

of excessive wear, wavy ring lands or fractures or damage

from detonation or pre-ignition.

Check the piston to cylinder bore clearance by measuring

the piston and bore diameters. Refer to the specifications

for the proper clearance. Refer to Cylinder Block Inspection

for the bore measurement procedure.

Measure the OD of

the piston with micrometers approximately 57.2 mm

(2-l/4 inches) below the dome and at 90 degrees to the

piston pin bore.

Check the ring side clearance.

Replace piston pins showing signs of fracture, etching or

wear. Check the piston pin fit in the piston and rod. Refer to

Piston and Connecting Rod Assembly.

Check the OD of the piston pin and the ID of the pin bore in

the piston. Replace any piston pin or piston that is not

within specifications.

Replace all rings that are scored, broken, chipped or

cracked. Check the end gap and side clearance.

Rings

should not be transferred from one piston to another

regardless of mileage or hours.

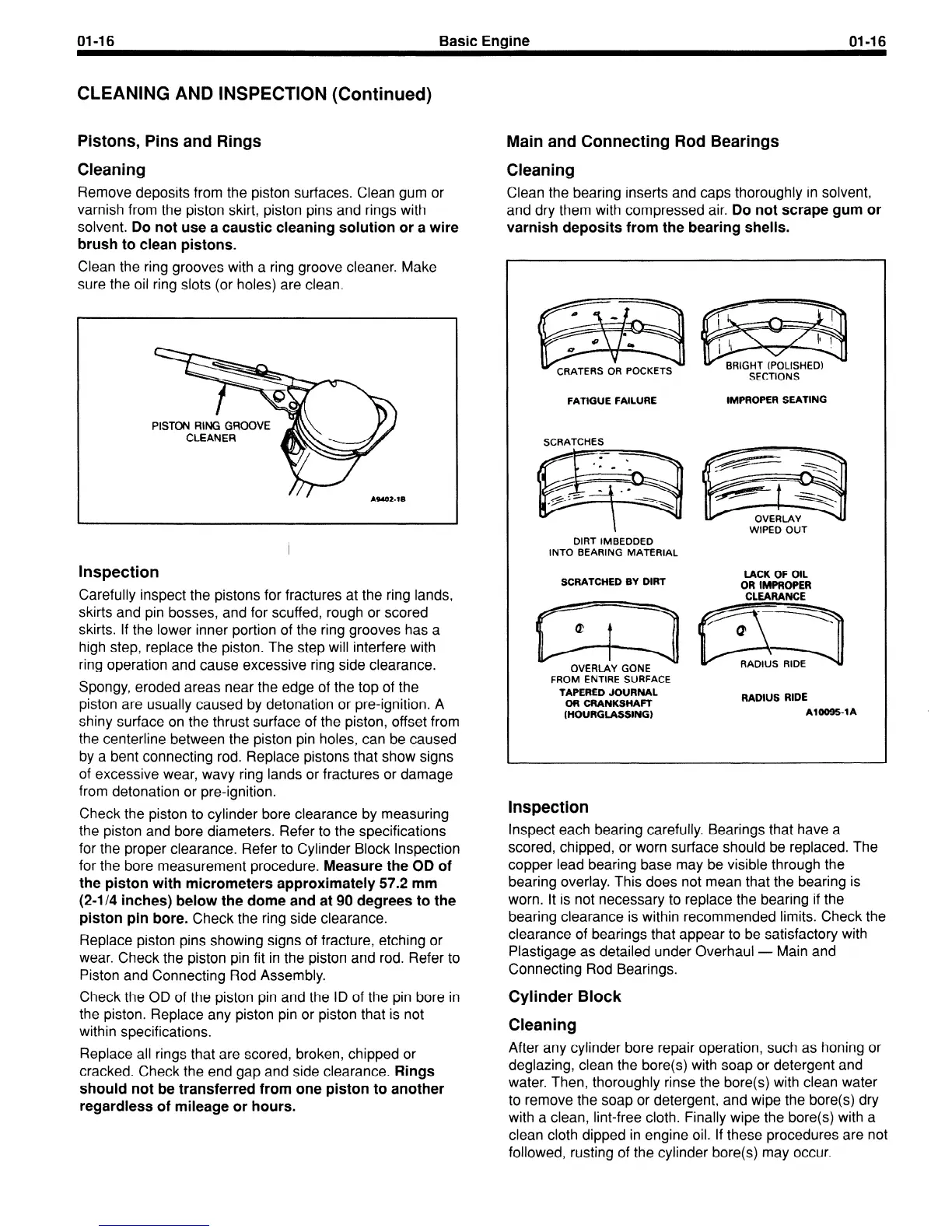

SECTIONS

FATIGUE FAILURE

MPROPER SEATING

SCRATCHES

WlPED OUT

DIRT IMBEDDED

INTO BEARING MATERIAL

SCRATCHED BY DIRT

LACK OF OIL

OR MWROPER

CLEARANCE

lc?izzil

FROM ENTIRE SURFACE

TAPERED JOURNAL

OR CRANKSHAFT-

RADIUS RIDE

(HOURGLASSING)

A100951A

Inspection

Inspect each bearing carefully. Bearings that have a

scored, chipped, or worn surface should be replaced. The

copper lead bearing base may be visible through the

bearing overlay. This does not mean that the bearing is

worn. It is not necessary to replace the bearing if the

bearing clearance is within recommended limits. Check the

clearance of bearings that appear to be satisfactory with

Plastigage as detailed under Overhaul - Main and

Connecting Rod Bearings.

Cylinder Block

Cleaning

After any cylinder bore repair operation, such as honing or

deglazing, clean the bore(s) with soap or detergent and

water. Then, thoroughly rinse the bore(s) with clean water

to remove the soap or detergent, and wipe the bore(s) dry

with a clean, lint-free cloth. Finally wipe the bore(s) with a

clean cloth dipped in engine oil. If these procedures are not

followed, rusting of the cylinder bore(s) may occur.

Loading...

Loading...