01-29

Basic Enaine

01-29

DISASSEMBLY AND ASSEMBLY

Engine Assembly

Disassembly

1.

2.

Mount the engine on a stand and drain crankcase.

Disconnect the fuel line at the fuel pump and

carburetor.

3. Disconnect the spark plug leads, remove them from

the clip on the rocker cover and position out of the

way.

4.

5.

Disconnect the water outlet and crankcase ventilation

hoses at the intake manifold.

Disconnect the wire from the temperature gauge

sending unit.

6.

7.

Disconnect the throttle rod from the carburetor.

Remove the governor mounting bolts and remove

governor and drive belt.

8.

9.

10.

11.

12.

Remove the thermostat housing and thermostat.

Remove the rocker arm cover and gasket.

Remove the rocker arm shaft bolts evenly and lift off

the rocker arm, shaft assembly.

Lift out the push rods from their locations and keep

them in their correct order.

Remove the cylinder head bolts and lift off the cylinder

head and gasket. Do not lay the cylinder head flat on

its face as damage to the spark plugs or gasket

surface can occur.

13.

14.

15.

16.

17.

18.

19.

Remove the fuel pump and oil pump.

Remove the dipstick and tube.

Remove the secondary wiring.

Remove fan, spacer, pulley and generator belt.

Remove the generator mounting and adjusting

bracket bolts. Remove generator.

Remove crankshaft pulley.

Remove tne water pump, front cover and crankshaft

oil slinger.

20. Remove any ridge and/or carbon deposits from the

upper end of the cylinder bores. Move the piston to

the bottom of its travel and place a cloth on the piston

head to collect the cuttings. Remove the cylinder

ridge with a ridge cutter. Follow the instructions

furnished by the tool manufacturer.

Never cut into

the ring travel area in excess of 0.8 mm (l/32 inch)

when removing ridge.

21.

Invert the engine on the stand and remove the oil pan

and gaskets.

22.

23.

24.

25.

26.

.

Remove the oil pick up tube and screen.

Remove the flywheel and tear engine plate.

Remove the tear bearing retainer.

Remove the timing chain tensioner.

Remove the camshaft sprocket and timinq chain.

27.

28.

29.

30.

31.

32.

33.

34.

Remove the camshaft thrush plate and the camshaft.

Remove the tappets keeping them in their correct

order.

Make sure all connecting rods and caps are marked

so that they can be installed in their original locations.

Partially loosen the connecting rod bolts several turns

and tap them to release the bearing caps. Remove

the bolts completely and remove the caps. Push the

pistons out of the bores and remove the assemblies.

Remove the main bearing caps bolts evenly and lift off

each cap. Lift out the crankshaft and handle with care

to avoid possible fracture or damage to finished

surfaces.

Remove the main bearings from block and cap.

Remove the thrust washers.

Disassemble the piston and connecting rod

assemblies. Remove the piston rings and the two

piston pin snap rings. Push the piston pin out of each

piston.

Remove the coolant drain plug and oil pressure

sending unit from the block.

Remove the block from the stand.

Assembly

When installing nuts or bolts that must be tightened (refer

to the torque specifications), oil the threads with light weight

engine oil.

Do not oil threads that require oil-resistant or

water-resistant sealer.

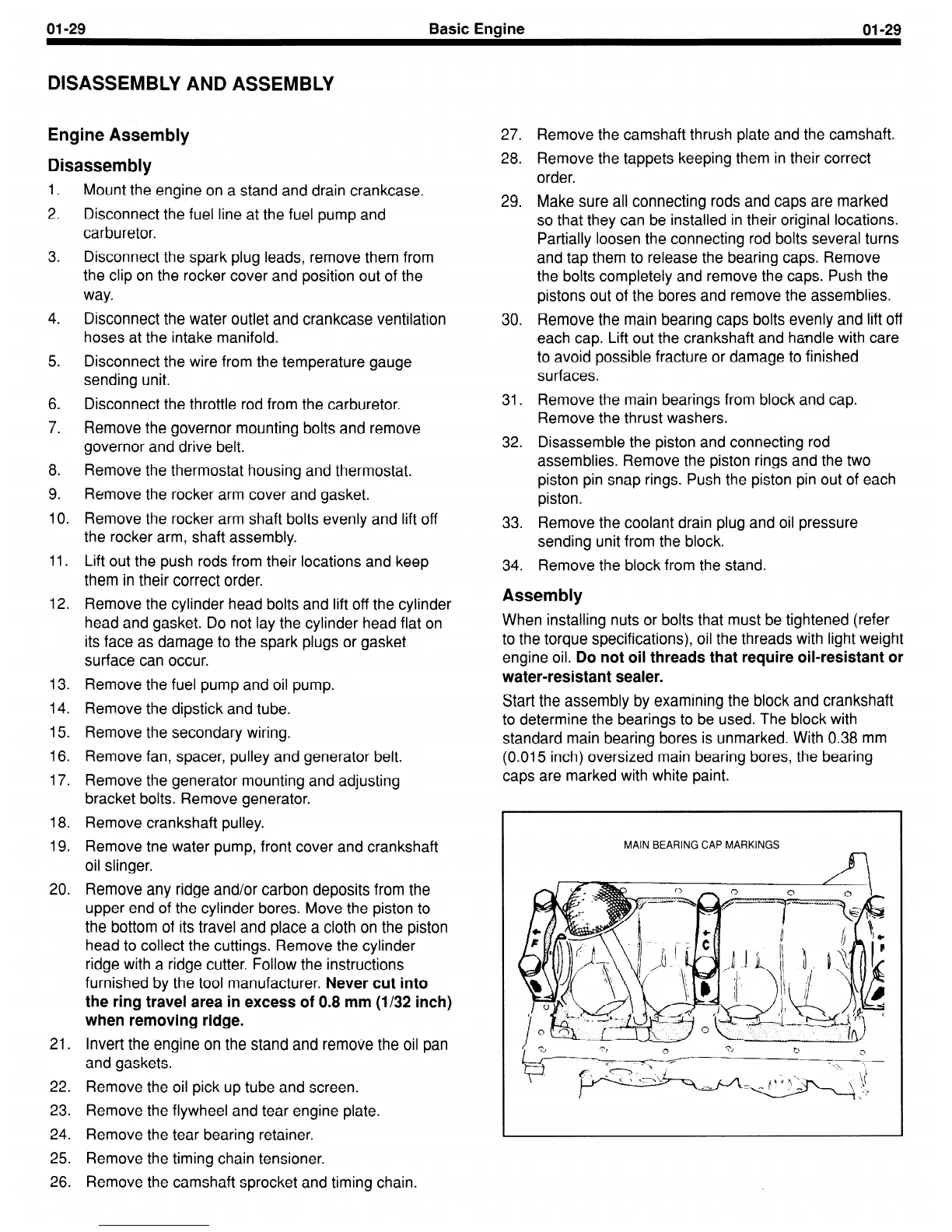

Start the assembly by examining the block and crankshaft

to determine the bearings to be used. The block with

standard main bearing bores is unmarked. With 0.38 mm

(0.015 inch) oversized main bearing bores, the bearing

caps are marked with white paint.

MAIN BEARING CAP MARKINGS

Loading...

Loading...