www.gemu-group.com24 / 76GEMÜ 1436 cPos

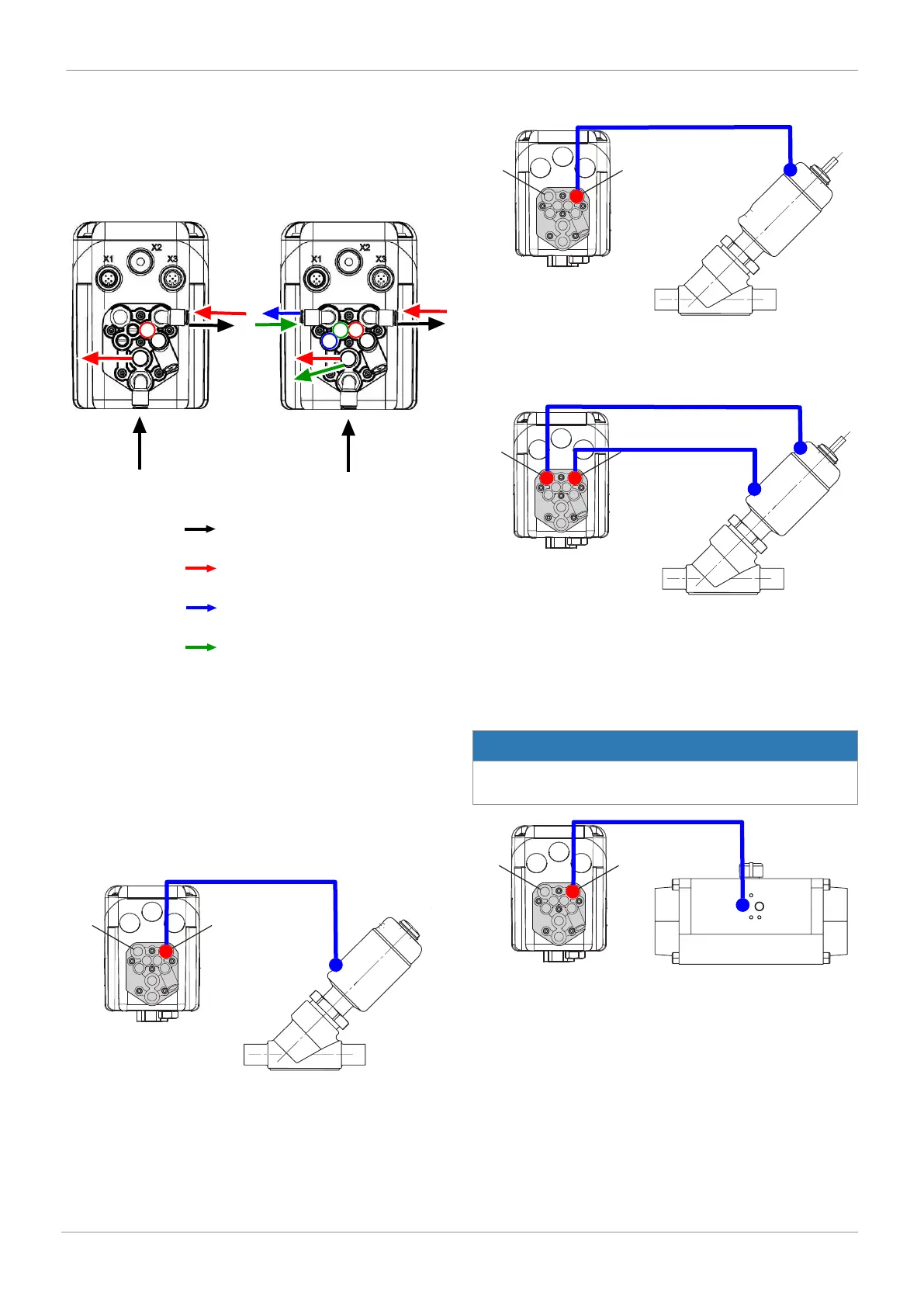

12 Pneumatic connection

1. Establish a connection between pneumatic positioner out-

let 2 (single acting) or connector 4 (double acting) and the

pneumatic control air inlet (control air inlets) of the actu-

ator.

2. Connect the auxiliary power (supply air) to air supply con-

nection 1 (max. 7 bar or 101 psi).

Single acting Double acting

Key

= Supply air (compressed air)/

working connection 2

= Exhaust air

working connection 2

= Supply air (compressed air)/

working connection 4

= Exhaust air

working connection 4

In order to regulate the flow rate and thereby the speed,

throttle screws (V1 and V2 single acting, V3 and V4 double

acting) are installed at the rear. See chapter "Setting the

throttle screws" for further information.

The connections to be used are fitted with push-in fittings for

tubes (outside diameter 6 mm) at the factory.

12.1 Connection diagram for linear actuators

12.1.1 Connection diagram for NC valves (Normally Closed)

● Fit tubing from 2 to the lower connection of the process

valve.

12.1.2 Connection diagram for NO valves (Normally Open)

● Fit tubing from 2 to the upper connection of the process

valve.

12.1.3 Connection diagram for double acting valves

● Fit tubing from 2 to the lower connection of the process

valve and 4 to the upper connection of the process valve.

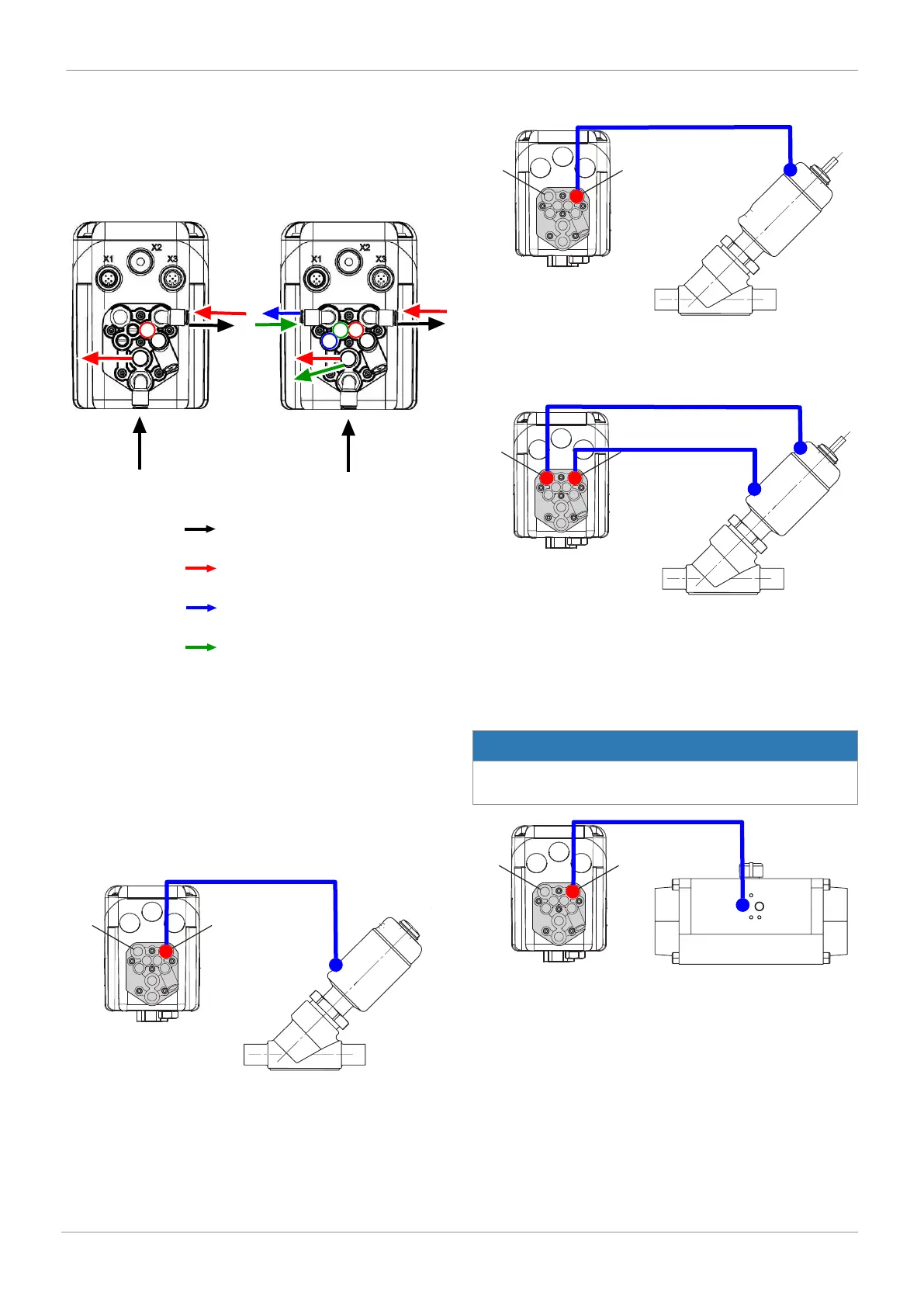

12.2 Connection diagram for quarter turn actuators

12.2.1 Connection diagram for NC/NO valves (Normally

Closed/Normally Open)

NOTICE

▶ The control function can be adjusted via the butterfly disc

or by turning the shaft.

● Fit tubing from 2 to connector 2 of the quarter turn actu-

ator.

Loading...

Loading...