2-1

SECTION 2: IGNITION

SECTION CONTENTS

PAGE

SPECIFICATIONS............................................................. 2-1

GENERAL INFORMATION................................................ 2-1

ARMATURES

Armature Testing ...................................................... 2-1

Removing Armatures ................................................ 2-1

Install Armatures........................................................ 2-1

Adjust Armature Air Gap .......................................... 2-2

FLYWHEEL

Remove Flywheel ...................................................... 2-2

Inspect Flywheel Key and Keyways ............................ 2-2

Install Flywheel .......................................................... 2-3

ENGINE WIRING HARNESS ............................................2-3

Testing Ground Wires ................................................ 2-3

Engine Wiring Harness Diagram ................................ 2-4

Diode Failure Diagnosis ............................................ 2-4

SPECIFICATIONS FOR

GTV-990/760 OHVI V-TWIN ENGINE

MODEL SERIES................................................ GTV-990/760

ARMATURE AIR GAP .............................. 0.20 TO 0.30 MM

(0.008" TO 0.012")

FLYWHEEL NUT TORQUE

FT. LBS. ........................................................................ 150

FLYWHEEL NUT TORQUE

NM .............................................................................. 203

See Section 1 For Spark Plug Maintenance And Specifications

GENERAL INFORMATION

Generac GTV-990/760 OHVI V-Twin engines use a magneto

ignition: an ignition armature with a self-contained transistor

module (no moving parts). Two magneto ignition armatures

are used, with a flywheel containing a permanent magnet.

NOTE: The magneto ignition system requires a minimum

of 250 RPM to produce a consistent spark.

ARMATURES

ARMATURE TESTING:

The condition of the ignition armatures can be accurately diag-

nosed using an ignition tester, (Generac P/N 0C5969) as

described in "Troubleshooting" in Section 1.

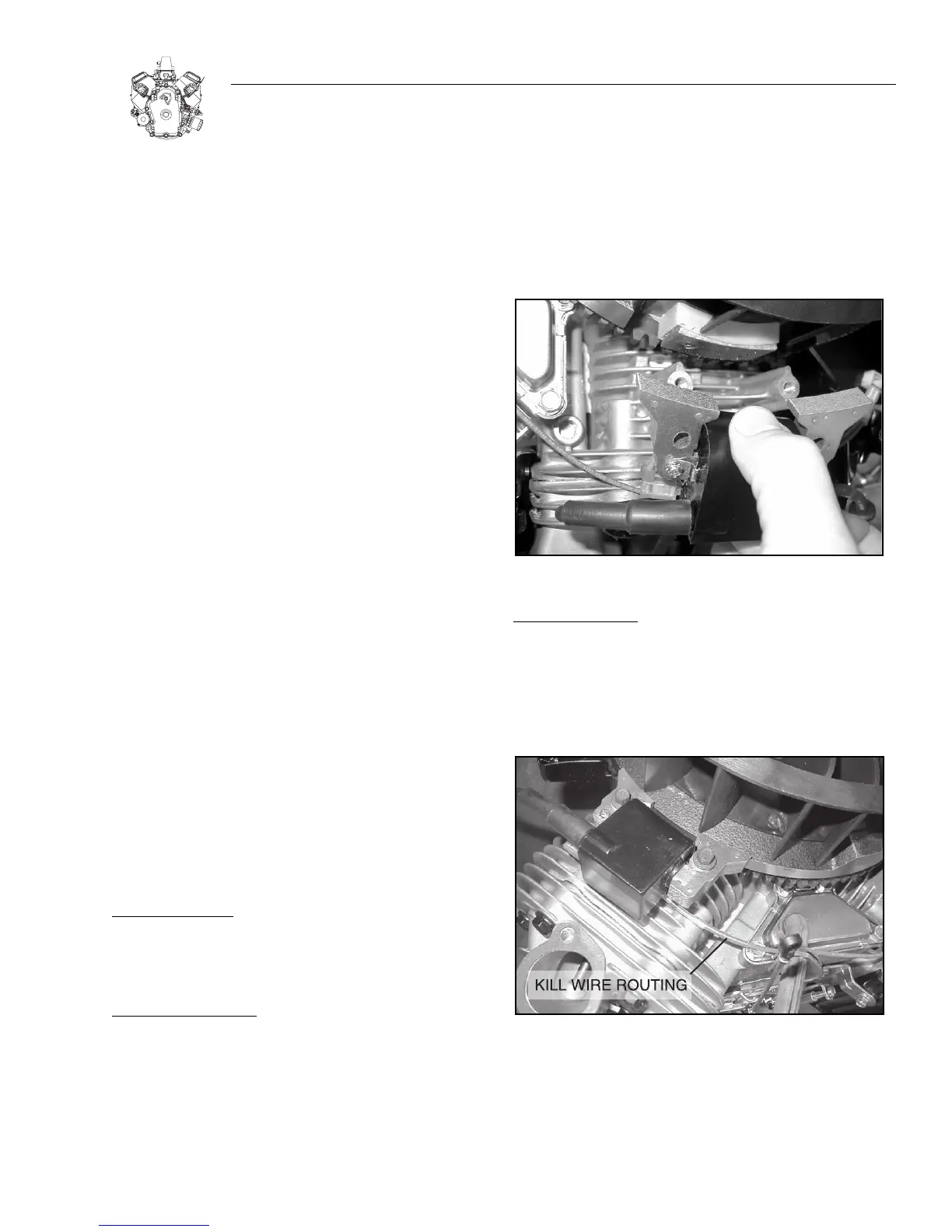

REMOVING ARMATURES:

1. Remove spark plug leads.

2. Remove intake manifold and cover intake ports.

3. Remove rotating screen and blower housing.

4. Remove armature screws and lift off armature(s),

Figure 2-1.

a. Disconnect stop switch wires at armatures.

Note:The flywheel does not need to be removed to ser-

vice ignition except to check the flywheel key.

Figure 2-1. Removing Armature

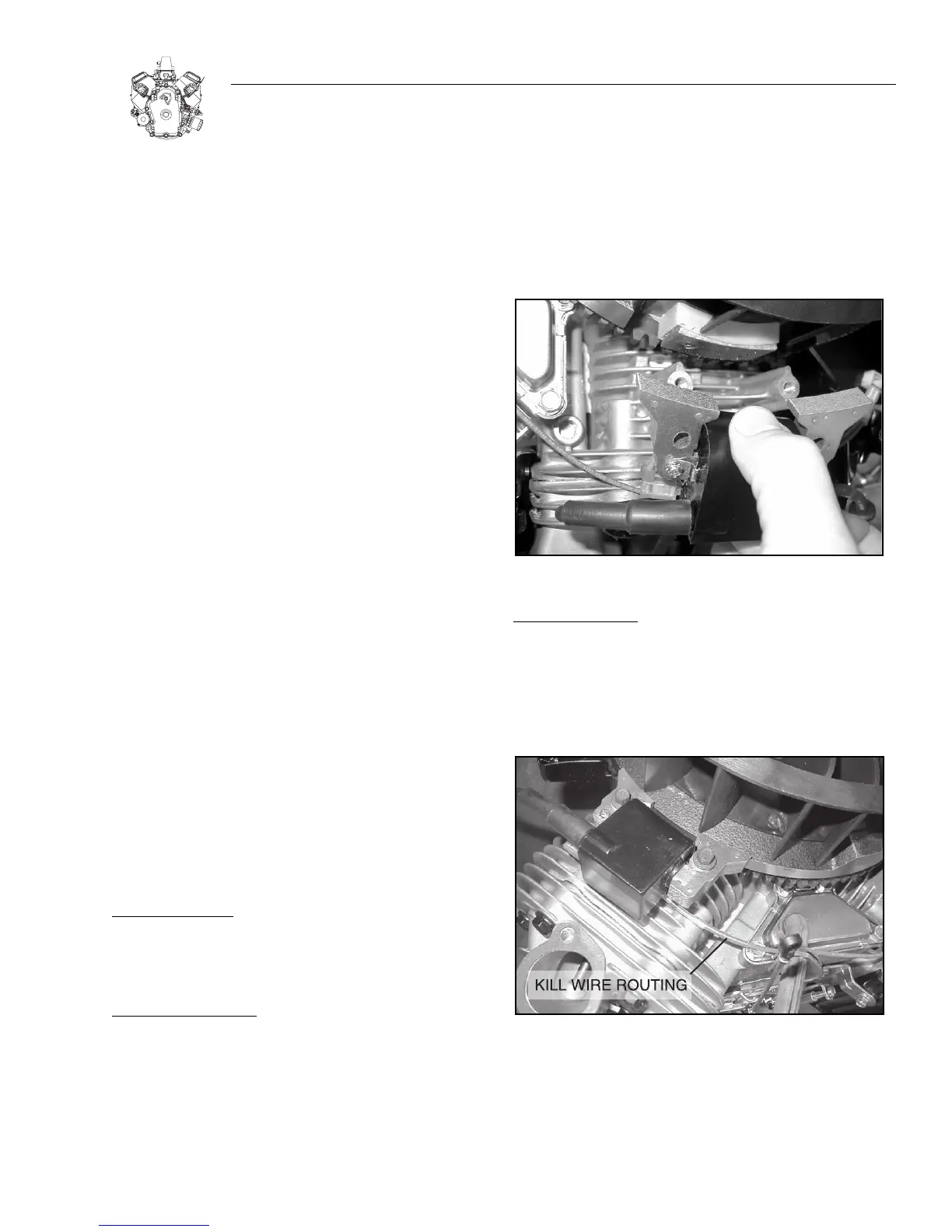

INST

ALL ARMATURES:

1. Turn flywheel so magnet is away from armature.

2. Install ground wire onto tab terminal on armature.

Note: Make sure wires are routed over armature mount-

ing posts and away from flywheel.

Figure 2-2. Installing Armature

3. Assemble armature to engine, Figure 2-2.

a. Mounting holes in armature are slotted. Push armature

away from flywheel as far as possible and tighten one screw

to hold armature in place.

Loading...

Loading...