SECTION 6: ELECTRIC STARTER

6-1

SECTION CONTENTS

PAGE

GENERAL INFORMATION................................................ 6-1

TROUBLESHOOTING ...................................................... 6-1

TEST EQUIPMENT .......................................................... 6-1

TEST STARTER MOTOR .................................................. 6-2

Testing Starter Solenoid.............................................. 6-2

BATTERY INFORMATION ................................................ 6-2

Installation ................................................................ 6-3

Checking Battery ...................................................... 6-3

Testing Battery .......................................................... 6-4

Battery Recommendations ........................................ 6-4

Battery Cable Recommendations................................ 6-4

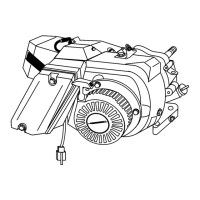

GENERAL INFORMATION

The starter motor uses a gear type engagement method, sim-

ilar to an automobile starter. When the starter motor is activated,

the pinion gear engages a ring gear attached to the engine

flywheel and cranks the engine.

Figure 6-1. Starter Motor

TROUBLESHOOTING

NOTE: If a starting problem is encountered, the engine

itself should be thoroughly checked to eliminate it as the

cause of starting difficulty. It is a good practice to check

the engine for freedom of rotation by removing the

spark plugs and turning the crankshaft over slowly by

hand, to be sure it rotates freely.

WARNING: DO NOT ROTATE ENGINE WITH ELECTRIC

STARTER WITH SPARK PLUGS REMOVED. ARCING AT

THE SPARK PLUG ENDS MAY IGNITE THE GASOLINE

VAPOR EXITING THE SPARK PLUG HOLE.

ENGINE CRANKS SLOWLY

:

a. Additional load affecting performance (see note above).

b. Discharged battery.

c. Faulty electrical connection (battery circuit).

d. Discharged battery (see alternators).

e. Dirty or worn starter motor commutator, bearing, weak

magnets, etc.

f. Worn brushes or weak brush spring.

g. Wrong oil viscosity for temperature expected.

h. Battery leads too long or wire too small.

i. Battery too small.

ENGINE WILL NOT CRANK:

a. Faulty safety interlocks.

b. Discharged or defective battery.

c. Faulty electrical connections.

d. Faulty starter motor switch (open circuit).

e. Open circuit in starter motor.

f. Brushes sticking, etc.

g. Faulty solenoid.

ST

ARTER MOTOR SPINS BUT DOES NOT CRANK ENGINE:

a. Sticking pinion gear due to dirt.

b. Damaged pinion or ring gear.

c. Battery faulty or damaged.

d. Incorrect rotation due to

reversed motor

polarity – all motors

rotate counterclockwise viewed from pinion gear.

e. Damaged solenoid

STAR

TER MOTOR SPINS BUT WILL NOT STOP:

a. Defective starter switch.

b. Solenoid stuck engaged.

TEST EQUIPMENT

The following is a list of equipment recommended to test and

repair starter motors.

DIGITAL MULTIMETER:

A digital multimeter (VOM) may be used to read volts, ohms,

amperes and test diodes (rectifiers), Figure 6-2.

NOTE: The Digital Multimeter is equipped with two fuses

to prevent damage to the meter in the event that the input

limits are exceeded. If the meter displays a reading of 0.00

when testing DC output, check fuses in meter. Refer to

VOM operators manual for procedure for checking fuses.

Loading...

Loading...