SECTION 5: CYLINDER HEAD AND VALVES

5-6

6. Install rotating screen.

a. Torque screws to 1.9 Nm (17 in. lbs).

7. Install finger guard.

a. If engine is equipped with hex head screws, torque screws

to 4.5 Nm (40 in. lbs).

b. If engine is equipped with finger screws, tighten screws

by hand to approximately 1.3 Nm (12 in. lbs.).

8. Assemble air cleaner.

WARNING: Before starting or running engine, static

adjustment of the governor must be completed!

Failure to make the static adjustments first could

result in engine overspeeding which may result in

engine damage, property damage or personal injury.

STATIC GOVERNOR ADJUSTMENT

1. With governor lever clinching screw loose, push on gov-

ernor lever until throttle is wide open. Do not bend governor

link or distort governor lever.

2. Rotate governor arm clockwise as far as it will go (Figure

5-20).

a. Torque clinching screw to 11.3 Nm (100 in. lbs).

3. Check to make sure that the throttle travels from WOT to

IDLE. If it doesn’t, the governor will need to be reset again.

4. Install throttle and choke control cables and check for

proper operation.

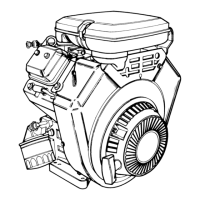

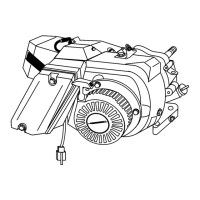

Figure 5-20. Static Governor Adjustment

Loading...

Loading...