Repair

26 312066ZAD

Repair

Before Beginning Repair

1. Flush if necessary; see Flushing.

2. Park component A pump.

a. Press .

b. Trigger gun until pump A stops. After fluid pres-

sure drops below 700 psi (7.9 MPa, 79 bar),

motor will run until component A pump is at bot-

tom of its stroke, then shut off.

c. Check ISO reservoir for component A pump. Fill

wet cup on component B pump. Refer to Reac-

tor Operation manual 312065.

3. Turn main power OFF .

4. Relieve pressure.

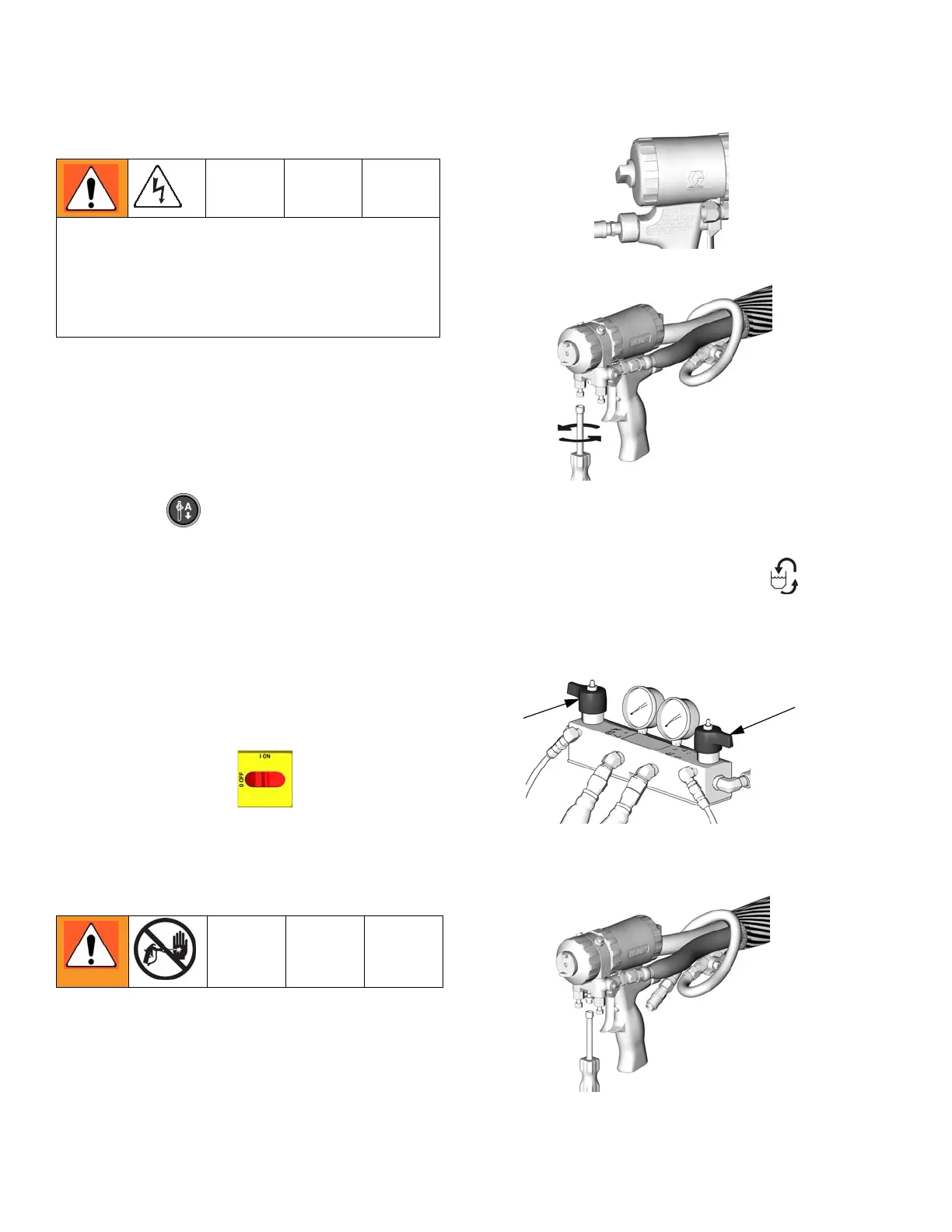

Pressure Relief Procedure

1. Relieve pressure in gun and perform gun shutdown

procedure. See gun manual.

2. Engage gun piston safety lock.

3. Close gun fluid manifold valves A and B.

4. Shut off feed pumps and agitator, if used.

5. Turn PRESSURE RELIEF/SPRAY valves (SA, SB)

to PRESSURE RELIEF/CIRCULATION . Route

fluid to waste containers or supply tanks. Ensure

gauges drop to 0.

6. Disconnect gun air line and remove gun fluid mani-

fold.

Repairing this equipment requires access to parts

that may cause electric shock or other serious injury if

work is not perfor med properly. Have a qualified elec-

trician connect power and ground to main power

switch terminals, see operation manual. Be sure to

shut off all power to the equipment before repairing.

ti2409a

ti2421a

SA

SB

ti2554a

Loading...

Loading...