Float switch

Configuration

1 2 3 4

2 - - - High level

1 - High level Dry running Dry running

Related information

8.1.1 Primary settings

8.1.4 Float switch functions

8.1.3 Pump delays

8.2.14 Start level variation

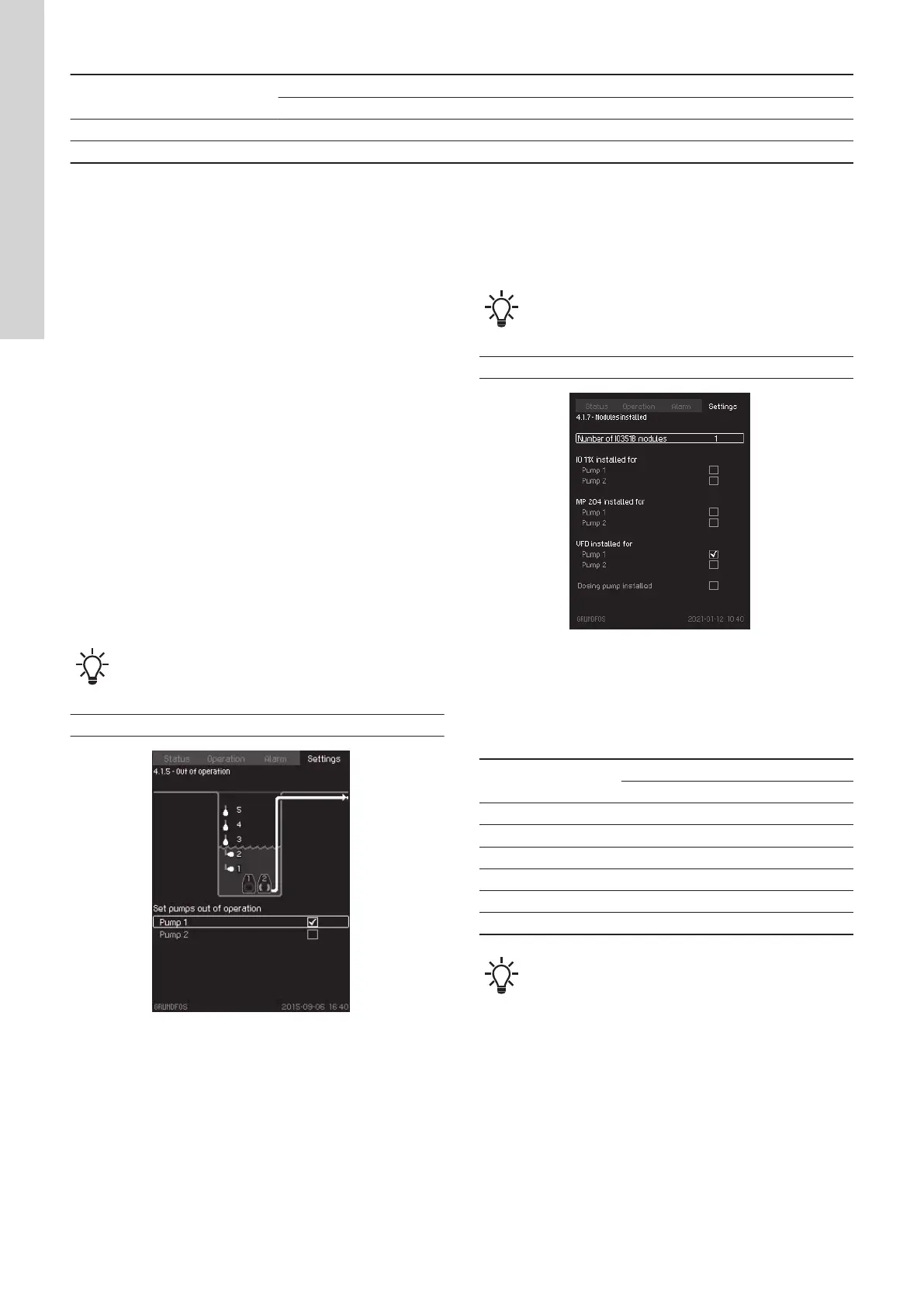

8.1.5 Out of operation

This display allows the user to take a pump temporarily out of

operation for service or due to operational disturbances.

When a pump is taken out of operation, it is removed from the list of

pumps that can be started. The system continues to operate with

the remaining pump(s).

Example 1

Select the pump to be taken out of operation.

• Pump 1 (out of operation)

• Pump 2 (in operation).

Example 2

Pump 1 is taken out of operation, and alternating operation is

enabled. The system continues to operate with only one pump. This

pump is now controlled by the start/stop levels for pump 2. This

applies no matter which of the pumps is taken out of operation. If

alternating operation is disabled, the remaining operating pump is

controlled by its own start/stop levels.

The user can take a faulty or inefficient pump out of operation.

Taking a pump out of operation removes the need to send its

alarms/warnings to the SCADA system.

The pumps always have a designated number, whether

alternating operation is enabled or disabled.

Path: Settings > Basic functions > Out of operation

4-1-5_OUT_OF_OPERATION_044

Out of operation

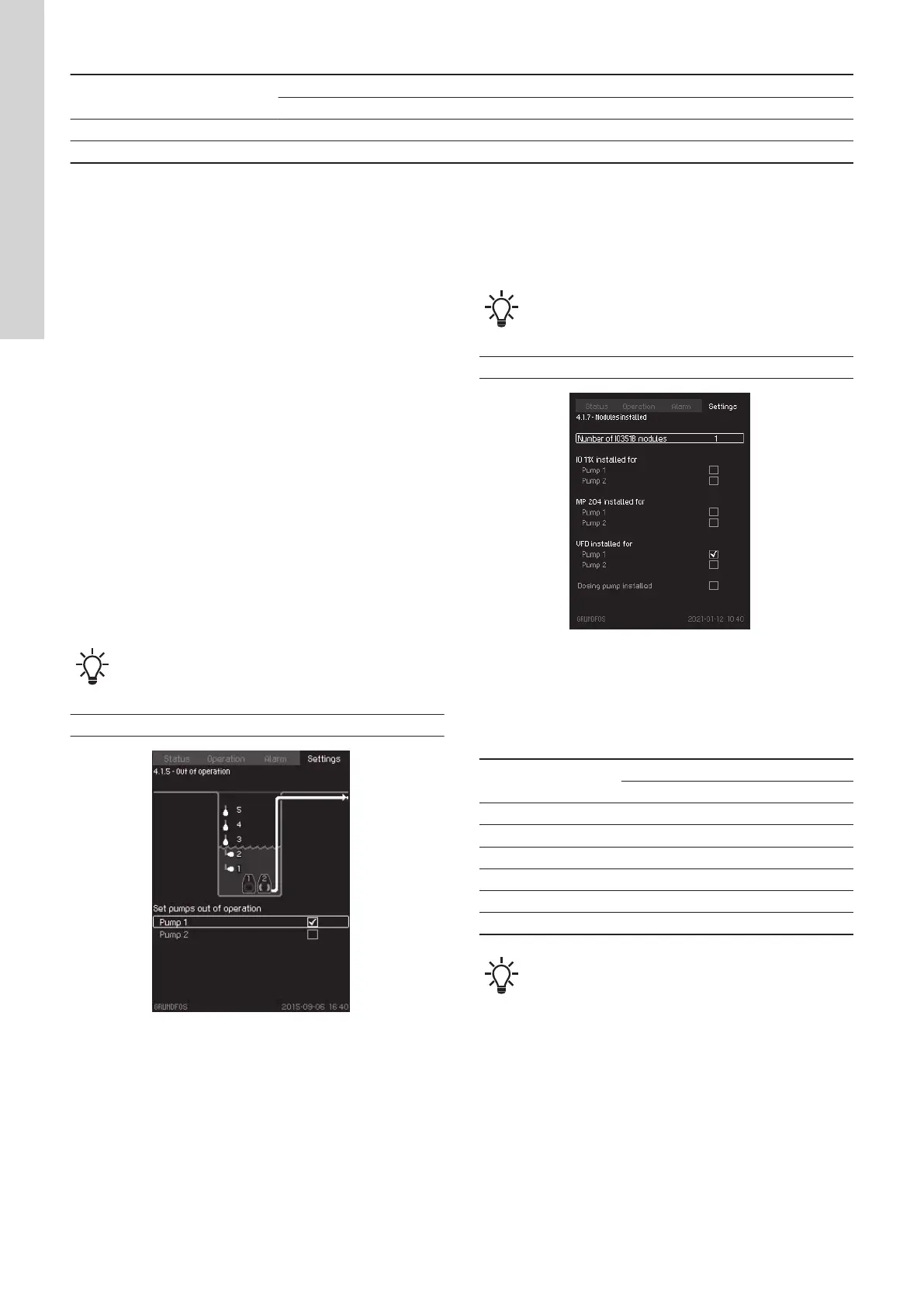

8.1.6 Modules installed

This display allows the user to configure the Dedicated Controls

system.

The number of IO 351B modules installed in the system must be

entered.

For each pump, tick the box if the mentioned module, motor

protector or frequency converter has been installed.

• IO 351B (maximum three modules).

• IO 113 (one module for each pump, maximum 6).

• MP 204 (one module for each pump, maximum 6). NOT to be

used together with a CUE or VFD.

• CUE or VFD.

When a module is selected, the data from the module can be seen

in the "Pump x" status display. See section about specific pump.

The status values depend on the actual configuration of the system.

These settings enable the modules selected

and the functions related to each module.

Path: Settings > Basic functions > Modules installed

TM078589

Modules installed

IO 113 installed for

Tick "Pump 1" or "Pump 2" to indicate that an IO 113 module has

been installed for that pump.

GENIbus number (address)

Pump number

Module

IO 113 * MP 204 ** CUE

1 9 (40) 1 1

2 10 (41) 2 2

3 11 (42) 3 3

4 12 (43) 4 4

5 13 (44) 5 5

6 14 (45) 6 6

The GENIbus number (address) can be set using the DIP

switches on the IO 113 module.

*The DIP switches on the IO 113 module must be set to bus

configuration if the IO 113 module is to be configured by use of a

PC Tool. See the installation and operating instructions for IO 113.

**MP 204 cannot be used together with CUE.

The Grundfos SM 113 module is partly supported, meaning

that only alarms are supported. Status values cannot be used or

seen on CU 362. When using SM 113 together with IO 113, IO 113

must have communication built in to support SM 113.

Related information

5.3 Specific pump

8.2

Advanced functions

The display shows the options in this menu.

30

English (GB)

Loading...

Loading...