3-90-00674R20_08/12

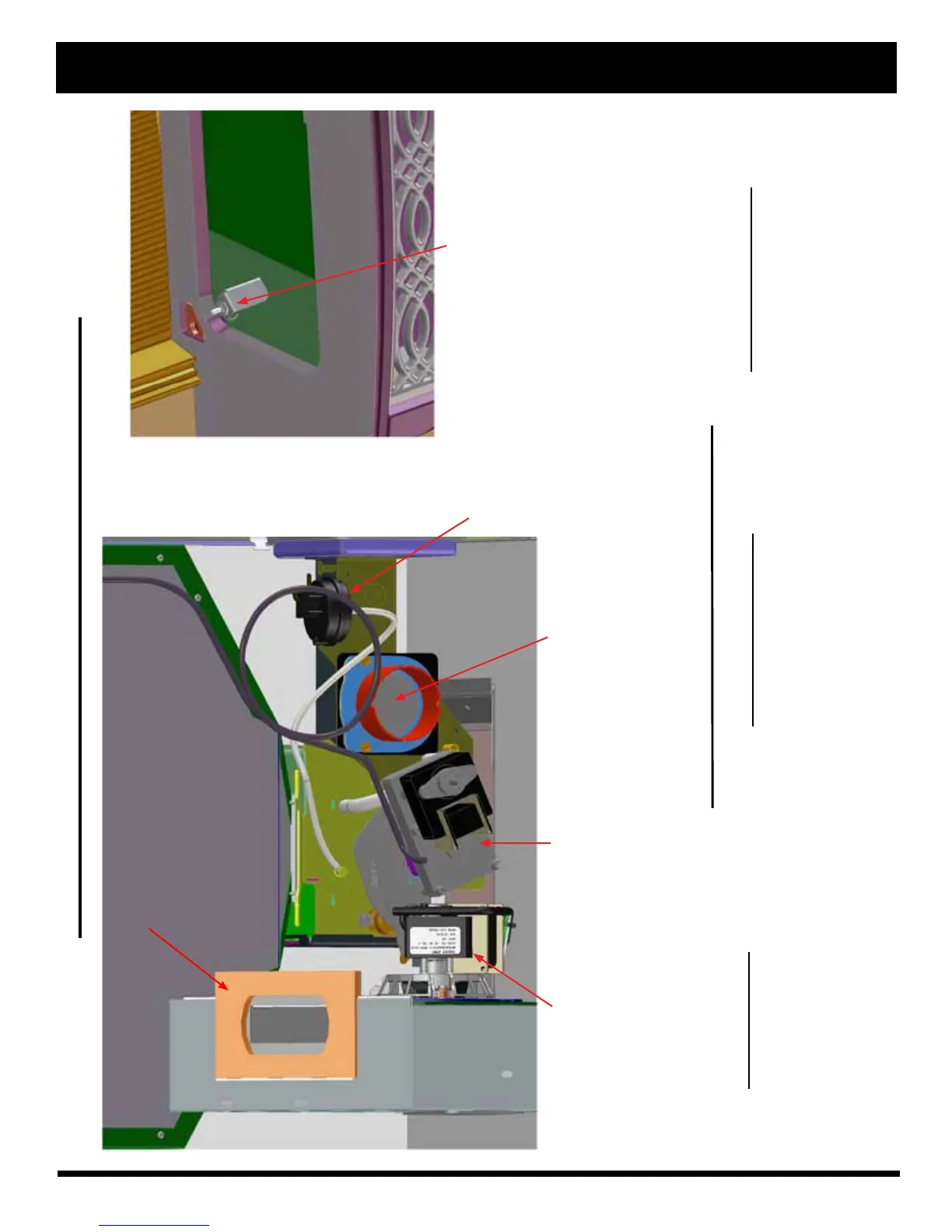

The is a differen-

tial pressure switch that monitors the negative pres-

sure (Draft) in the rebox. If the draft becomes too

low for proper combustion, the switch opens, cutting

power to the feed motor and the igniter circuits. This

switch is connected into the AC (high voltage) wiring.

The combination is re-

sponsible for all high limit safety control. There are

2 high limits, one normal operation high limit and

one backup high limit. The control has an automatic

diagnostic circuit that continuously monitors the ESP

and Room Sensor for faults. If a fault should occur,

the control sends a status alert and at the same time

the unit goes down to minimum feed/minimum burn

as a safety condition.

Always check to see if the damper

plate swings freely inward and that

the seating edges are not covered

with dirt or lint.

Low Draft

Pressure

Switch

Feed Motor

Combustion Motor

Distribution Blower

(under unit)

See Fig. 10, Page 9.

Silicone

sponge

docking

gasket

The is found in

the rear corner of the hopper opening. If the hopper

lid is not fully closed, the switch opens, interrupting

the power to the feed motor and the igniter circuits.

This prevents possible injury from reaching into the

feeder mechanism during operation.

Hopper Lid

Position

Switch

Loading...

Loading...