7-46

M4GB-01-0004

M4GB-07-044

M4GB-07-049

M4GB-07-050

1. Park the machine on solid level surface. Lower the bucket

to the ground. Stop the engine.

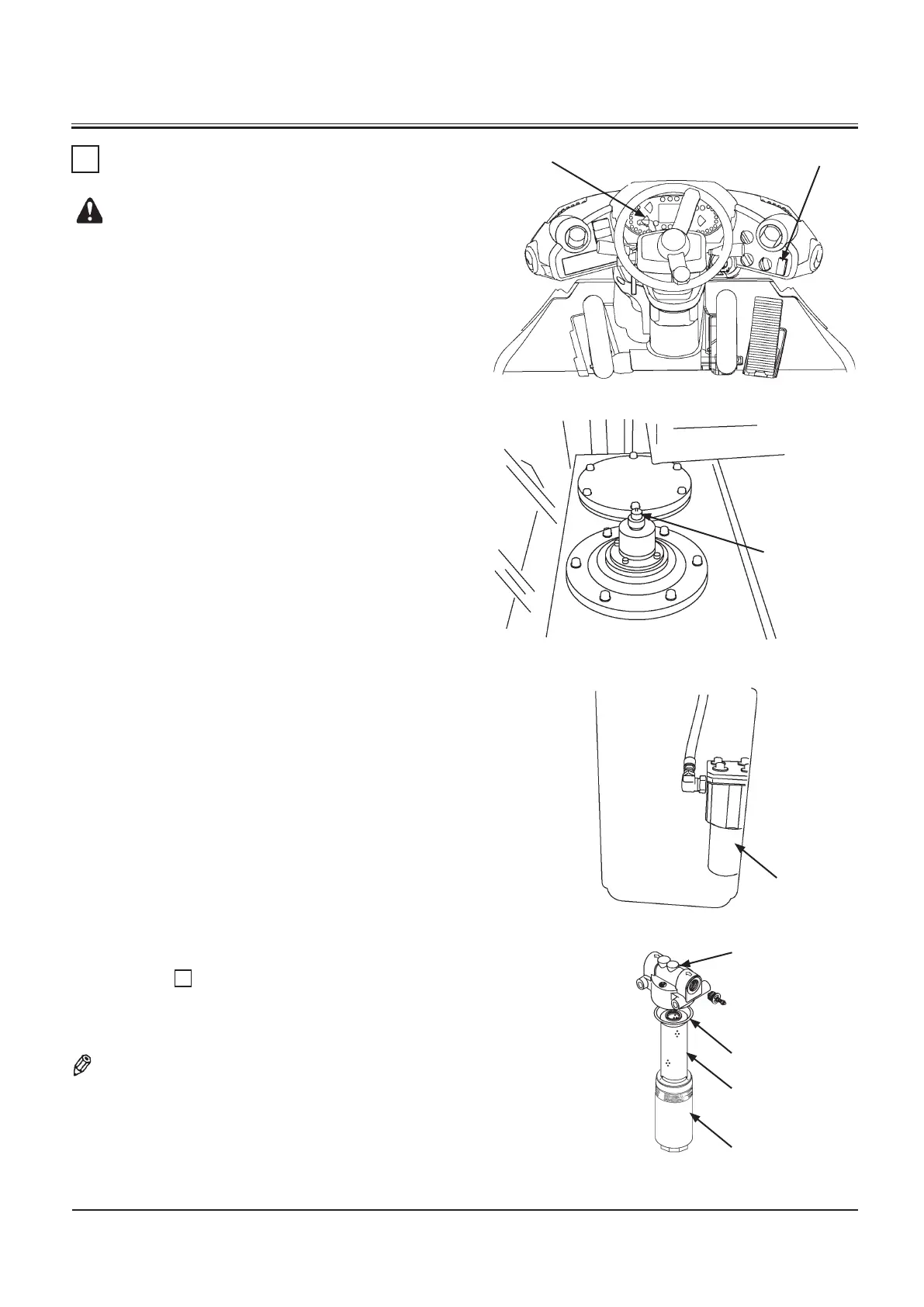

2. Turn the parking brake switch (1) ON. Press the neutral

lever lock (2) to the LOCK position.

3. Lock the front and rear frames with the articulation lock

bar.

4. Before replacing the filter element, be sure to relieve the

air pressure from the hydraulic oil tank by pressing air

bleed valve (3).

5. Remove the inspection cover for left side rear frame.

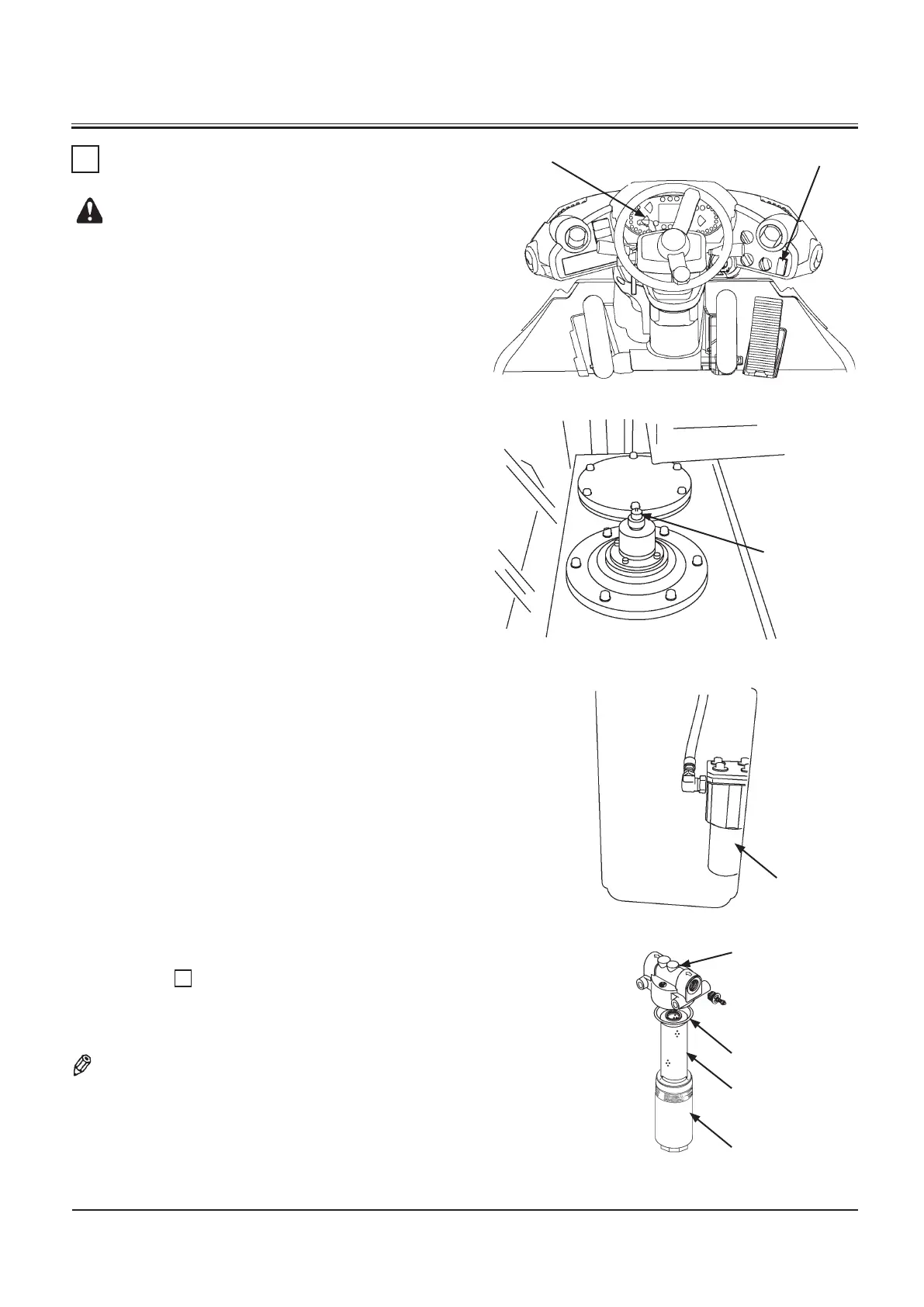

6. Rotate the hexagonal section on the bottom of case (4)

counterclockwise using a spanner to remove case (4)

from head cover (5).

7. While turning element (7), remove the element down

-

ward.

8. Replace O-ring (6) with a new one.

9. Sufficiently seat O-ring (6) in the O-ring groove on head

cover (5).

10. Coat the seal surface of new element (7) with hydraulic

oil. While turning element (7), completely install element

(7) into head cover (5) using care not to damage the ele

-

ment.

11. Take care never to allow water and/or dust to enter the

filter case.

12. Install case (4) into head cover (5) while rotating case (4)

clockwise.

Tightening torque: 39 N•m (4 kgf•m)

19.6 to 29.4 N•m (2 to 3 kgf•m)

13. After replacing the filter, bleed air from the hydraulic

pump and check the oil level in the hydraulic oil tank.

[Refer to the descriptions for “Bleed air from the hydraulic

system” in

2

.] If the machine is operated without bleed-

ing the air mixed in the hydraulic circuit, damage to the

hydraulic pump may result.

NOTE: Replace the element at the regular intervals to main

-

tain the clean hydraulic oil and extend the service life-

time of the hydraulic components.

4

Loading...

Loading...