7-51

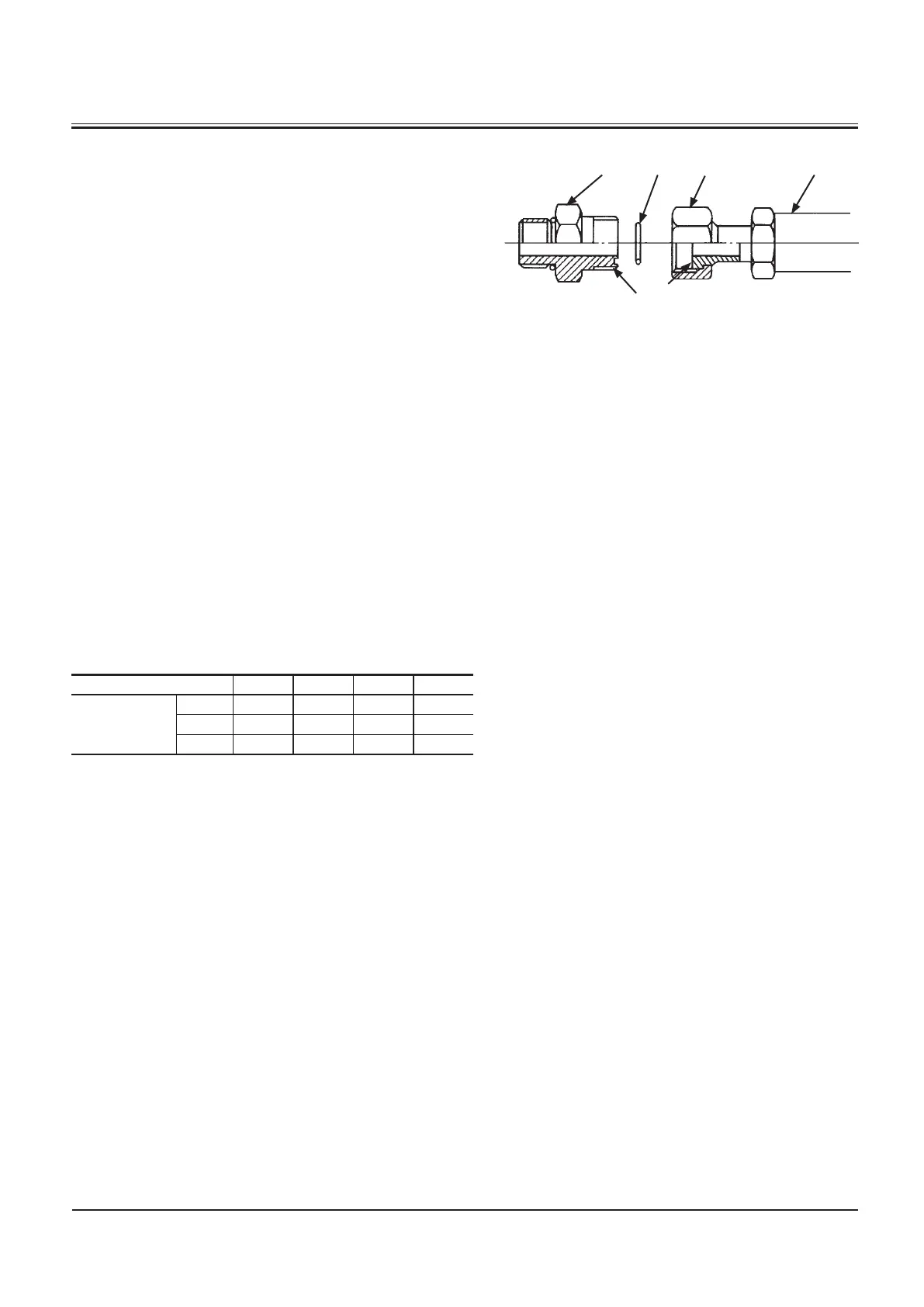

Two hydraulic fitting designs are used on this machine.

An O-ring is used on the sealing surfaces to prevent oil leak

-

age.

1. Inspect fitting sealing surfaces (6). They must be free of

dirt or defects.

2. Replace O-ring (1) with a new one when assembling fit

-

tings.

3. Lubricate O-ring (1) and install it into groove (3) using

petroleum jelly to hold it in place.

4. Tighten fitting (2) by hand, pressing the fitting joint to

-

gether to ensure O-ring (1) remains in place and is not

damaged.

5. Tighten fitting (2) or nut (4) to the torque values shown.

Do not allow hose (5) to twist when tightening fittings.

6. Check for leaks. If oil leaks from a loose connection, do

not tighten fitting (2). Open the connection, replace

O-ring (1) and check for correct O-ring position before

tightening the connection.

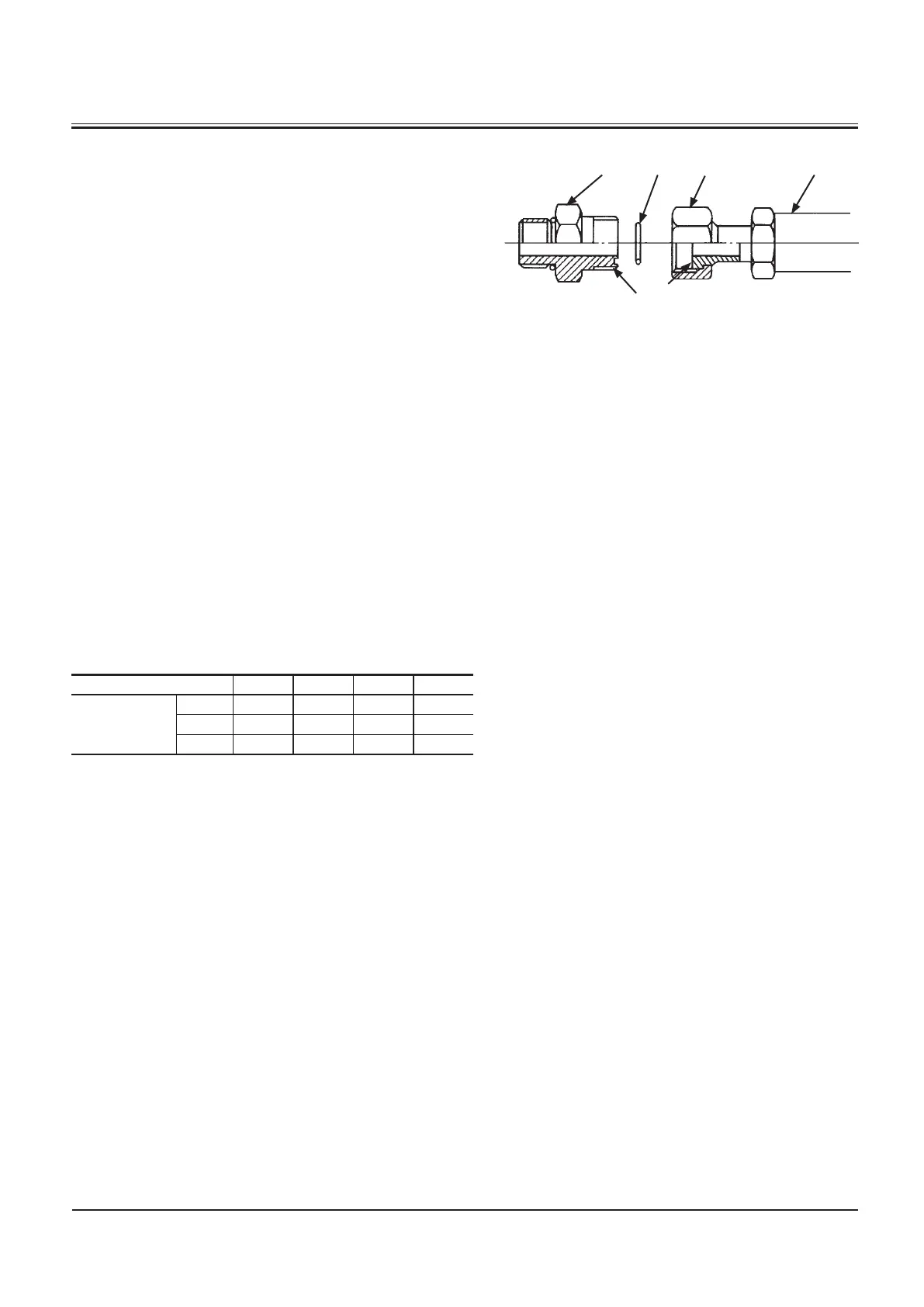

Torque specifications ±10%

Width across flats (mm) 27 32 36 41, 46

Fastening

torque

N•m 93 132 176 206

(kgf•m)

(9.5) (14) (18) (21)

(lbf•ft)

(69) (101) (130) (152)

M104-07-033

Loading...

Loading...