XNX Universal Transmitter

Section 3 - Calibration

101

Gas Calibration Menu

Each of the sensor technologies supported by the transmitter uses

unique calibration procedures. The description provided illustrates the

transmitter interface with the sensor. The description does not replace

the procedures found in each sensor’s operating manual.

The Gas Calibration menu is used for Zero and Span calibration as

well as functional testing (bump testing). The Gas Calibration menu is

accessed from the Main Menu.

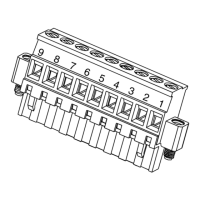

This table shows the Gas Calibration menu icons:

Symbol Description

Gas Calibration

Bump Test

Calibrate mA Output

Soft Reset

Align Excel

✓

Figure 191. Gas Calibration Menu

For calibrating sticky gases (Cl

2

, ClO

2

, HF, HCl, HCN, F

2

and O

3

), use

Tox Kit part number XNXTOXKIT2.

Default Calibration Values

Warning: Do not use the transmitter in oxygen-enriched atmospheres. Concentrations displayed will

be adversely affected by oxygen depletion.

Warning: Take appropriate precautions when using toxic, ammable, or pressurized cylinders.

Caution: The calibration procedure must be performed only by qualied personnel.

The default calibration values for the “Calibration Required” diagnostic

vary based on sensor type. This value can be reprogrammed in

accordance with site requirements to ensure the highest level of safety.

Before commissioning, verify the correct operation of each sensor

by calibration with a certied test gas of known concentration. See

Specications for calibration gas specications.

Caution: Recalibrate if the temperature of local environment has varied by more than ±15°C from the

temperature of calibration.

!

Warning: Honeywell recommends periodic bump tests (every 30 days or in accordance with

customer site procedures) to the sensor to insure proper operation and compliance with the functional

safety rating of the installation.

Loading...

Loading...