22

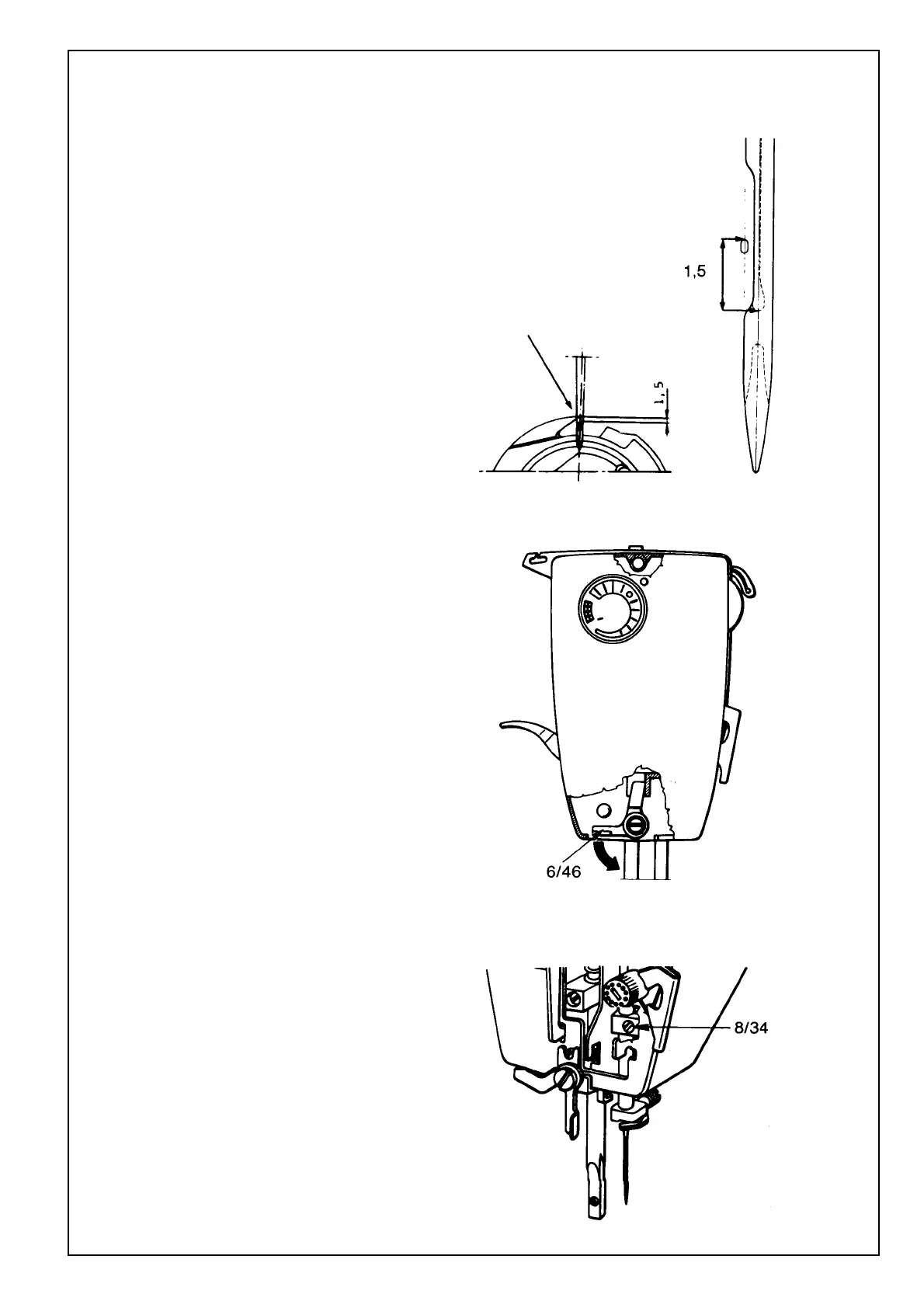

The upper position of the needle bar

Requirements

When the tip of the hook passes the centre of the

needle, the gap between the tip and the upper

edge of the needle eye should be 1.5 mm.

Comments

The gap between the tip of the hook and the

needle eye is influenced by the timing of the

hook in relation to the needle. Check

according to page 20 before any adjustment

is made.

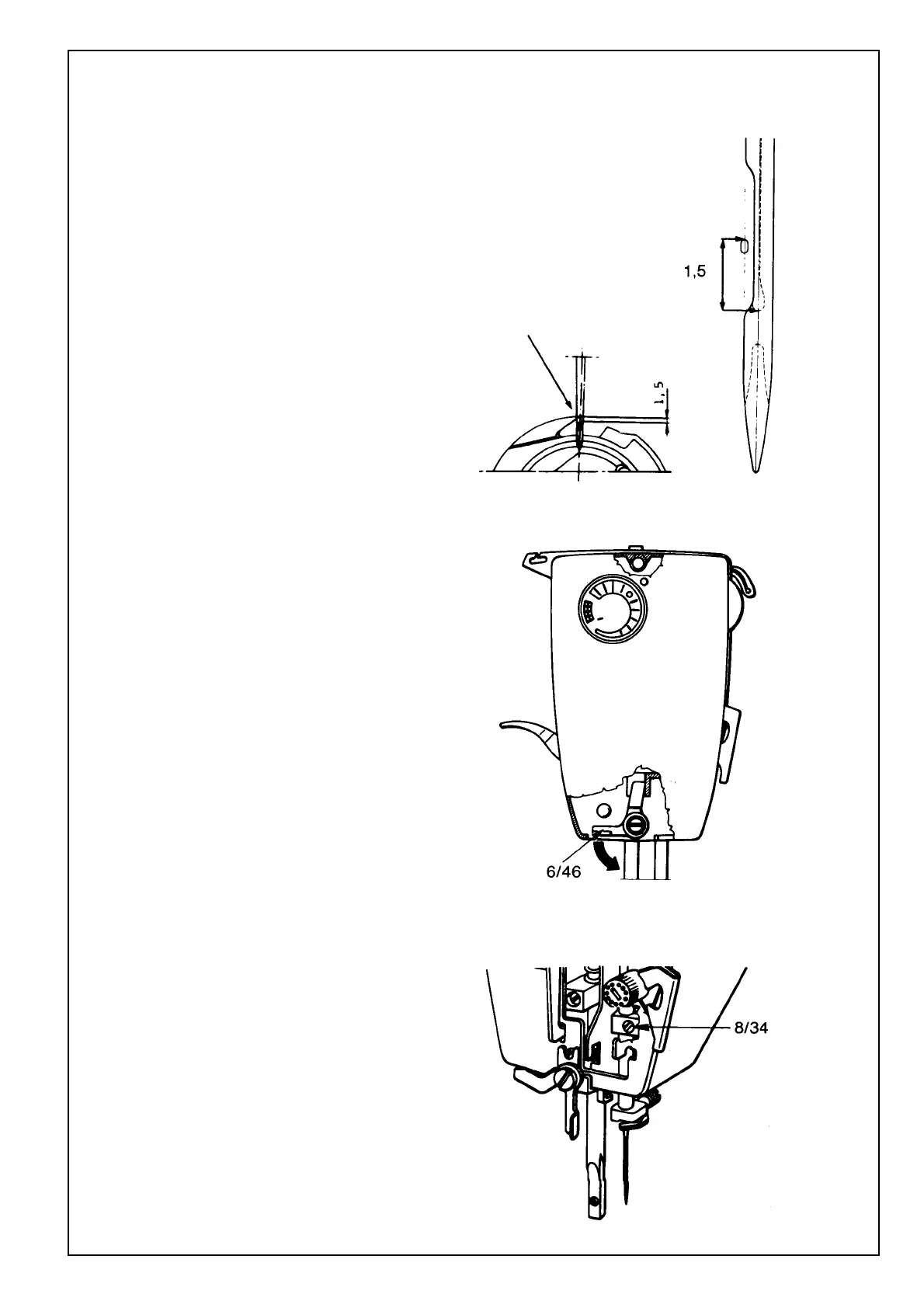

Adjustment

Remove the front cover.

The catch located under the lower edge of the

front cover should be drawn downwards and

the lower part of the cover lifted out from the

machine. The cover can now be lifted upwards,

so that it releases from the upper shoulder screw.

Press the button for straight stitching. Turn the

handwheel until the needle is at the lower turning

position. Push the hook downwards and then

hold it fast, so that the catch of the hook rests

against the left side of the driver slot. Turn the

handwheel until the tip of the hook reaches the

centre of the needle. Loosen the screw (8/34) on

the crank rod pin. Move the needle bar axially

until the gap between the upper edge of the

needle eye and the tip of the hook is 1.5 mm.

Before tightening the screw (8/34) check that the

needle eye is at right angles to the hook.

Comments

As the needle bar is made in the form of a tube,

the screw must not be tightened too hard. There

is a risk of the needle bar becoming deformed

and thereby moving stiffly in its bearings.

Spare parts: See RA page 8.

NOTE!

The tip of the hook

at the centre of the

needle

Setting of the upper

position of the needle

Loading...

Loading...