36

The movement of the needle

bar frame (zig-zag movement)

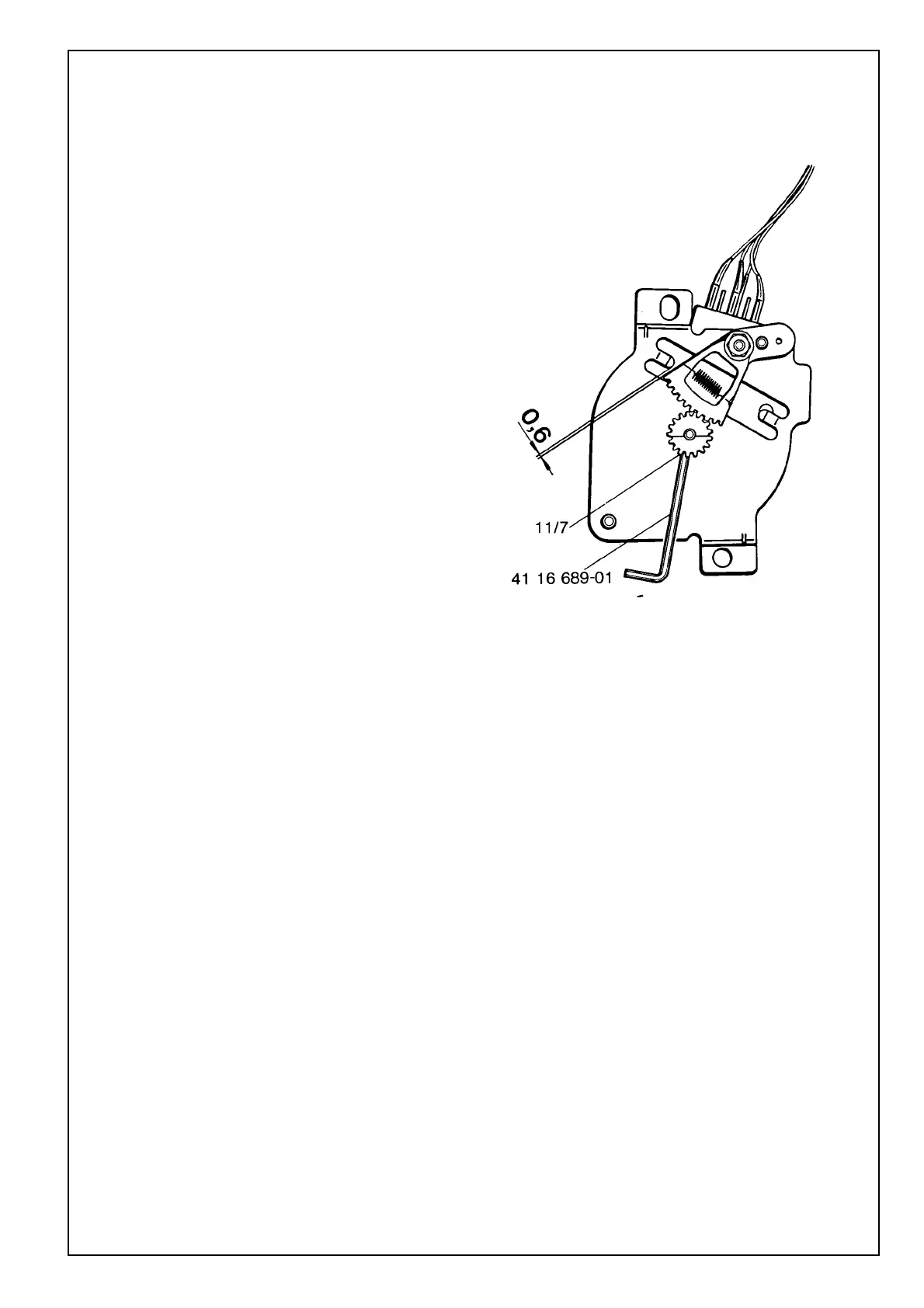

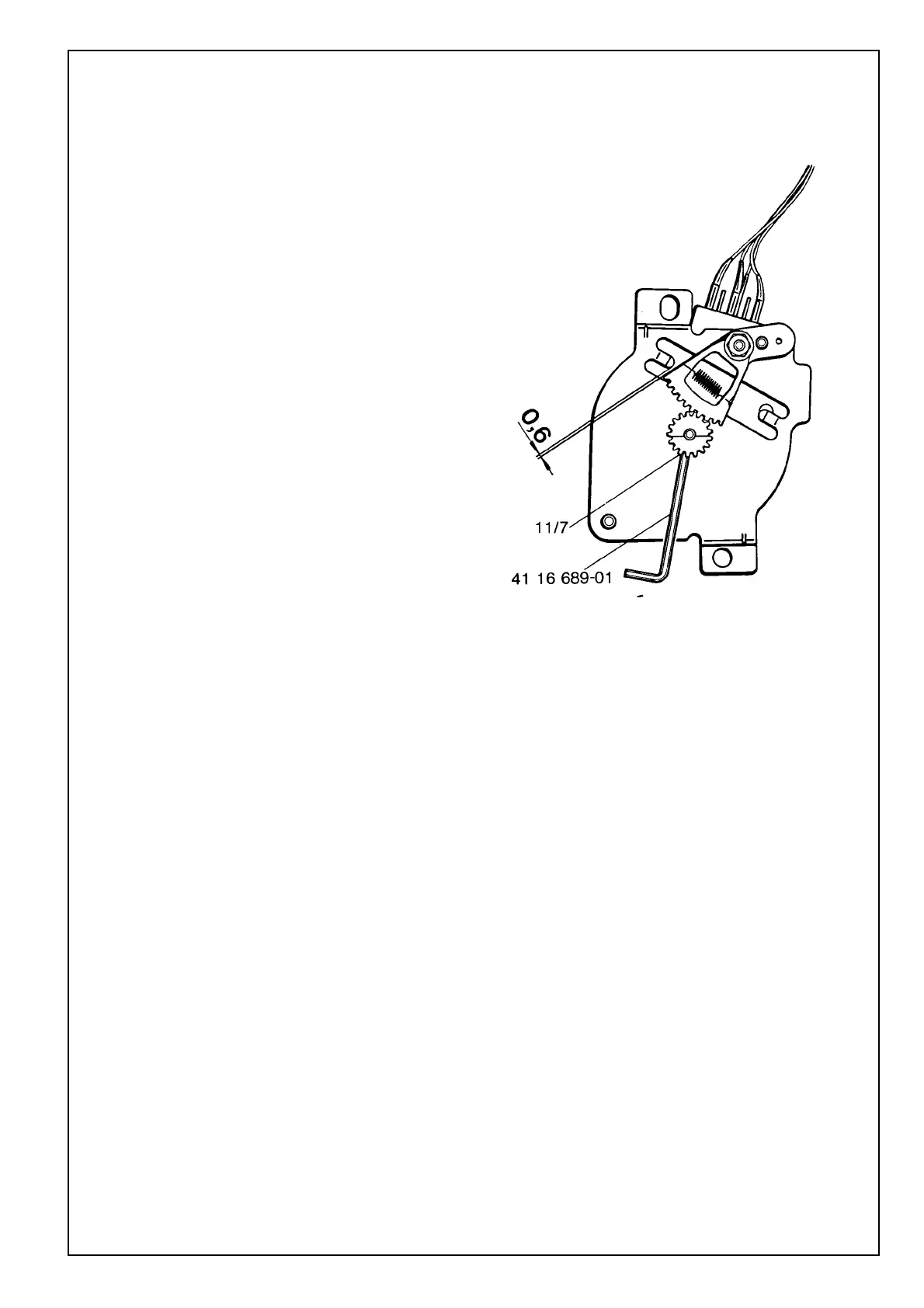

Pre-setting of the step motor.

Do not mount the step motor but connect the flat

cable from the front panel, the transformer and the

step motor to the circuit in the rear cover. Note that

the wire of the step motor is connected to the upper

outlet on the printed circuit.

Connect the machine and turn on the main switch.

Replace the handwheel but note that the thread

take-up lever shall be at the lowest position. Press

the button for changing the stitch width, causing the

upper light to light up. Hold the drive side of the step

motor towards you and insert a 0.6 mm feeler gauge

at the left projection of the segment and press the

segment against the projection. Turn the handwheel

2-3 revolutions and stop with the needle in the upper

position. The step motor will find its electrical starting

point, i.e. the needle is in the left zig-zag position.

Retain slight axial play in the cogwheel and well

tighten the set screw (11/7) in the driving gear, but do

not overdo it. Press the mirroring button. The

segment will go over to the right-hand position (the

right-hand zigzag position of the needle). Check that

the segment is not touching the projection on any side.

Slow the shaft of the step motor down with your thumb

and repeatedly turn the main switch on and off. Check

that the step motor occupies a stable middle position.

Loading...

Loading...