26

The presser bar,

tangential setting

Requirements

The presser bar should be set in such away that

the needle hole in the presser foot coincides

with the needle hole in the stitch plate.

Adjustment

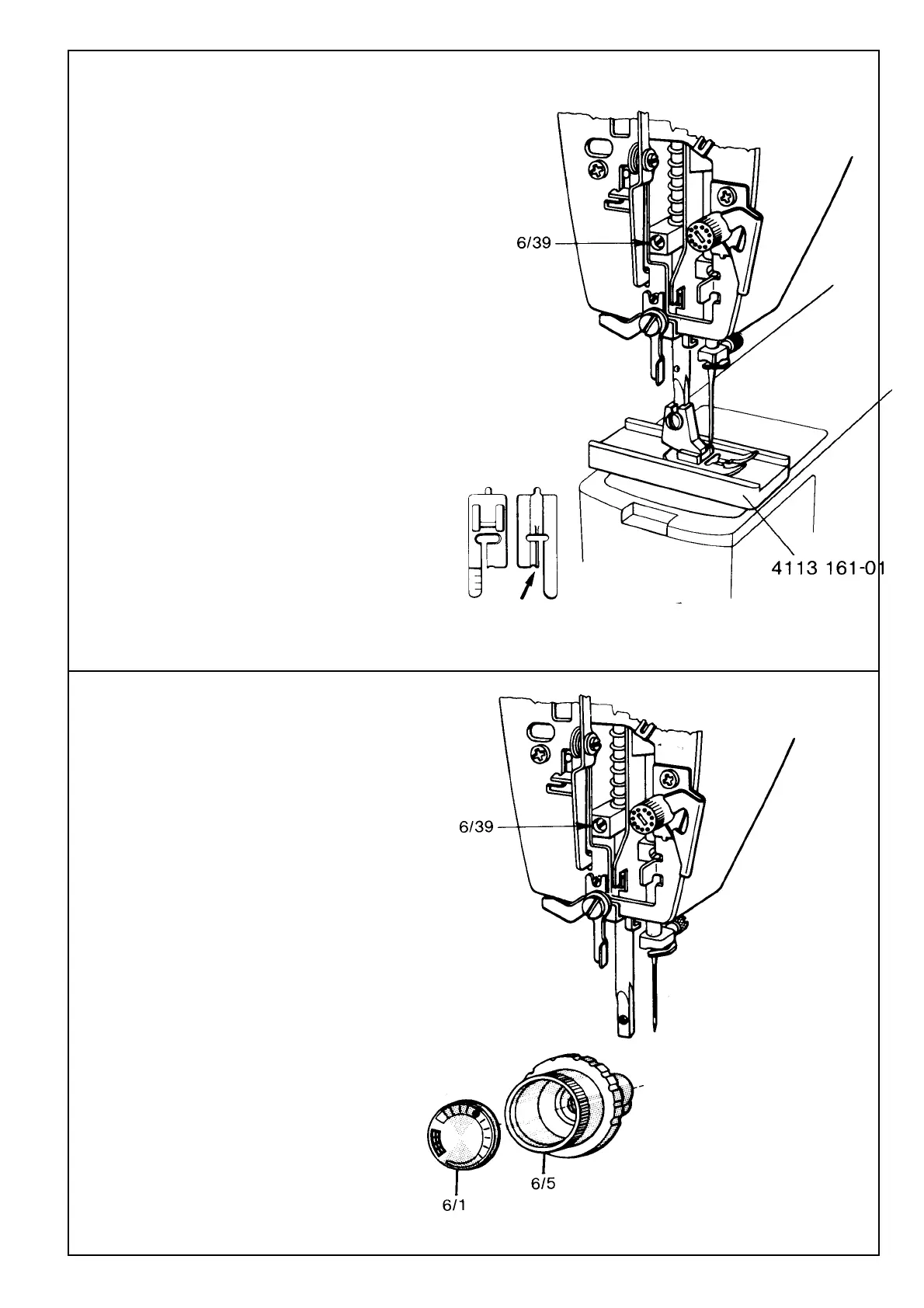

The gauge 411 3161-01 for adjustment of the

presser bar should be placed on the stitch plate.

Drop the feed dog. The presser bar lever should

be lowered and the screw in the presser bar guide

(6/39) loosened. Fit the presser foot into the groove

of the gauge and position the edge of the gauge

parallel with a marking line, according to the sketch.

Check that the underside of the presser bar guide

touches the presser bar level. The screw (6/39)

should then be tightened.

Comments

On the underside of the buttonhole foot

there is a guide, which steers the fabric.

If the position of the presser bar is not

correct in relation to the needle, the

distance between the columns will be affected.

Pressure foot pressure

Requirements

The pressure between the presser foot and the

stitch plate should be sufficient to hold the fabric

in place.

Adjustment

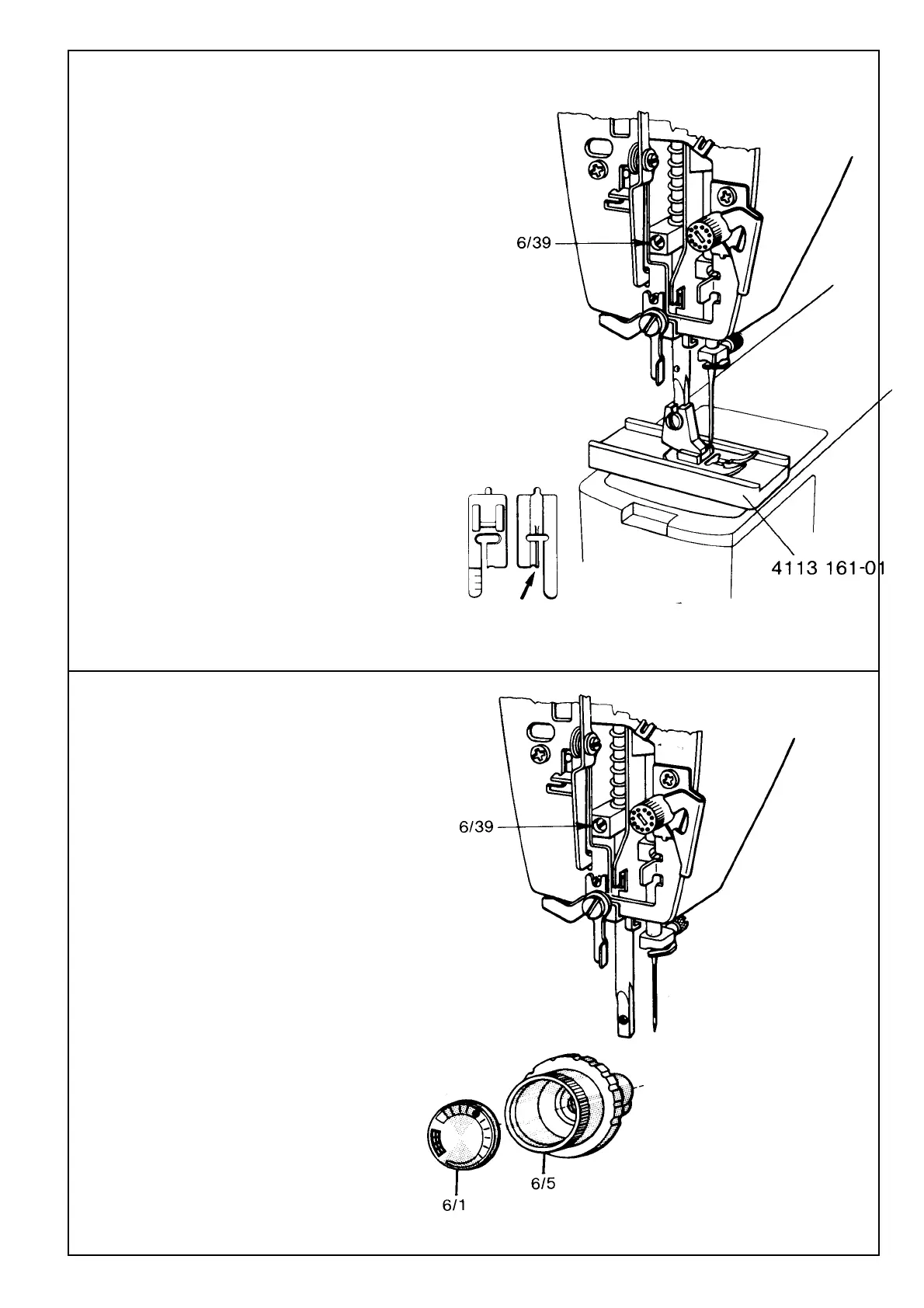

Set the presser bar knob at red and drop the presser

bar. Check that there is no seizing, by lifting the

presser bar with the sole holder. If the required

pressure cannot be achieved by the presser bar

spring, this can be altered by changing the position

of the red dot on the knob cover. This cover (6/1) can

be removed by inserting a sharp tool under the edge

and gently pulling it outwards. Set the required presser

bar pressure and replace the cover, ensuring that

the red dot is in front of the white mark on the

face plate.

Comments

How the fabric is held between the

presser foot and the stitch plate plays an

important role in the stitching.

Spare parts: See RA, page 6.

Loading...

Loading...