Installation and maintenance manual

H.I.B Hydac International Page 23 of 36

Version: G/DV

Date: 11.01.2023

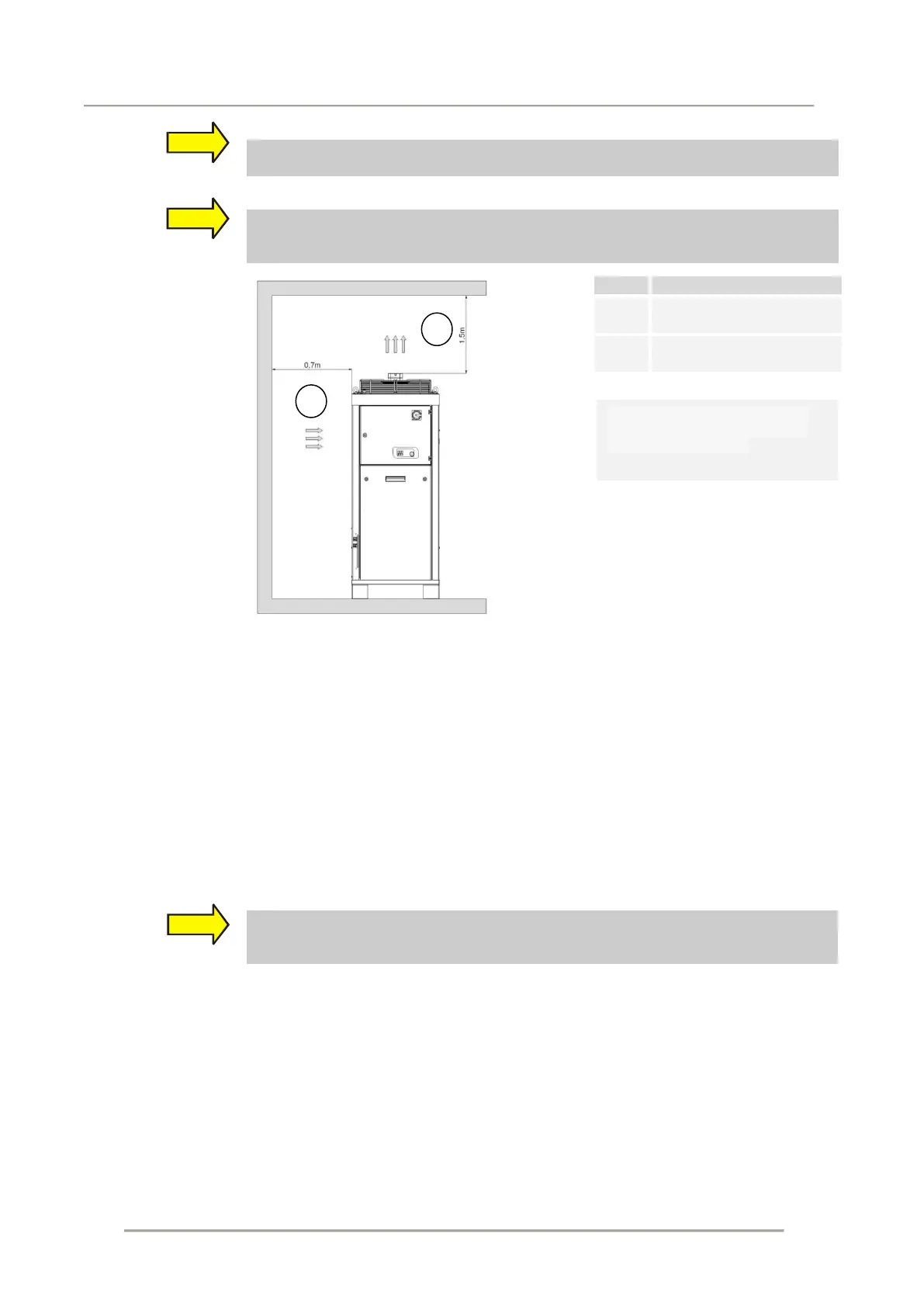

The operating equipment must be easily accessible. Between 0.6 and 1.9 metres (1.7

metres recommended) above the access level.

The cooling air must be able to circulate freely. Any air intake and outlet channels

must provide their own suction i.e. they must contain compensation bellows. The

fitting of air-conducting device has to be agreed with the manufacturer.

Air inlet

- S7/G7/G8 = 2,0m

Air outlet

- S7/G7/G8 = 5,0m

schematic diagram (see dimension sheet)

10.2 Hydraulic connection

The connections and the liquid circuits are to be positioned by experts in accordance with the

technical regulations.

The following must be observed:

Select suitable material for the hydraulic connection of the cooler

Select a suitable cross section to avoid pressure loss

Insulate tubes 5m long and over to prevent heat loss

If the consumer is located above the cooler, attach a solenoid valve in the return flow and

a non-return valve in the supply flow of the cooler. Reason: tank overflow

If parts of the cable or other connected elements are higher than the intended level of

liquid placed as the return flow of the coolant at a stationary plant is to be prevented

with proper facilities.

Recommended distance may be

less than for compressor / water

or water / water chiller.

Loading...

Loading...