OperatiOn

powermax

65/85

Service Manual 4-9

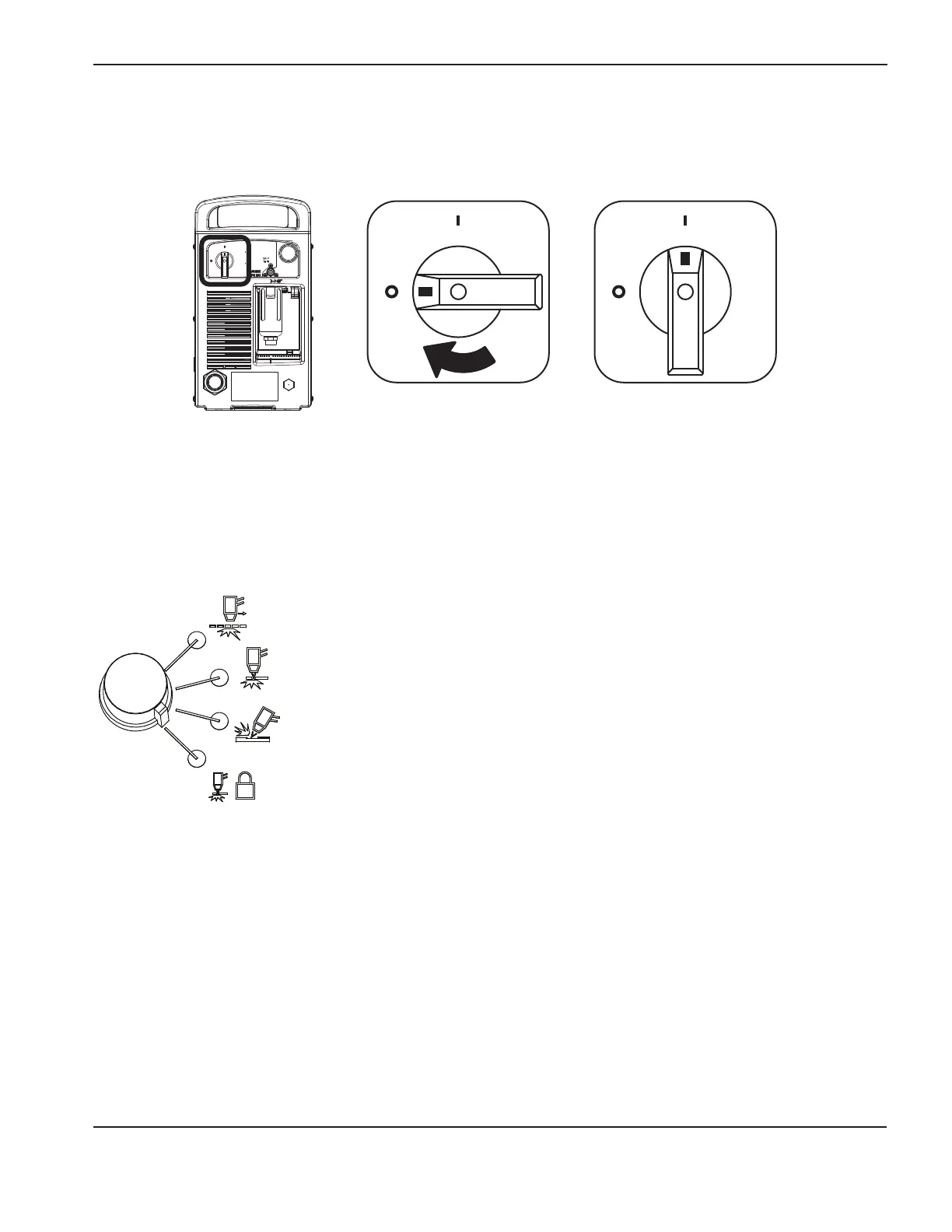

Set the operating mode switch

Use the operating mode switch to select the type of work you want to perform.

In automatic gas mode, Smart Sense™ technology automatically adjusts the gas pressure according to the selected

cutting mode and torch lead length for optimum cutting.

For cutting expanded metal, grates, metal containing holes, or any job that requires a

continuous pilot arc. Using this mode to cut standard metal plate reduces consumable

life.

For cutting or piercing metal. This is the standard setting for normal drag-cutting.

For gouging metal. (Note: Using this mode while cutting results in poor cut quality.)

Locks the torch in the ON (fire) position. With this option selected, press the trigger to

fire the torch. You can then release the trigger while continuing to cut. Press the trigger

again to stop the arc. The arc also stops if you lose transfer.

Turn ON the system

Set the ON/OFF switch to the ON (I) position.

Off

On