Power suPPly setuP

2-6 powermax

45

Service Manual

Generator recommendations

Generators used with the Powermax45 should satisfy the following requirements:

CSA

• 1-phase, 50/60Hz, 230/240VAC

• 3-phase, 50/60Hz, 480VAC

CE

• 1-phase, 50/60Hz, 230VAC

• 3-phase, 50/60Hz, 380/400VAC (400VAC recommended for best performance)

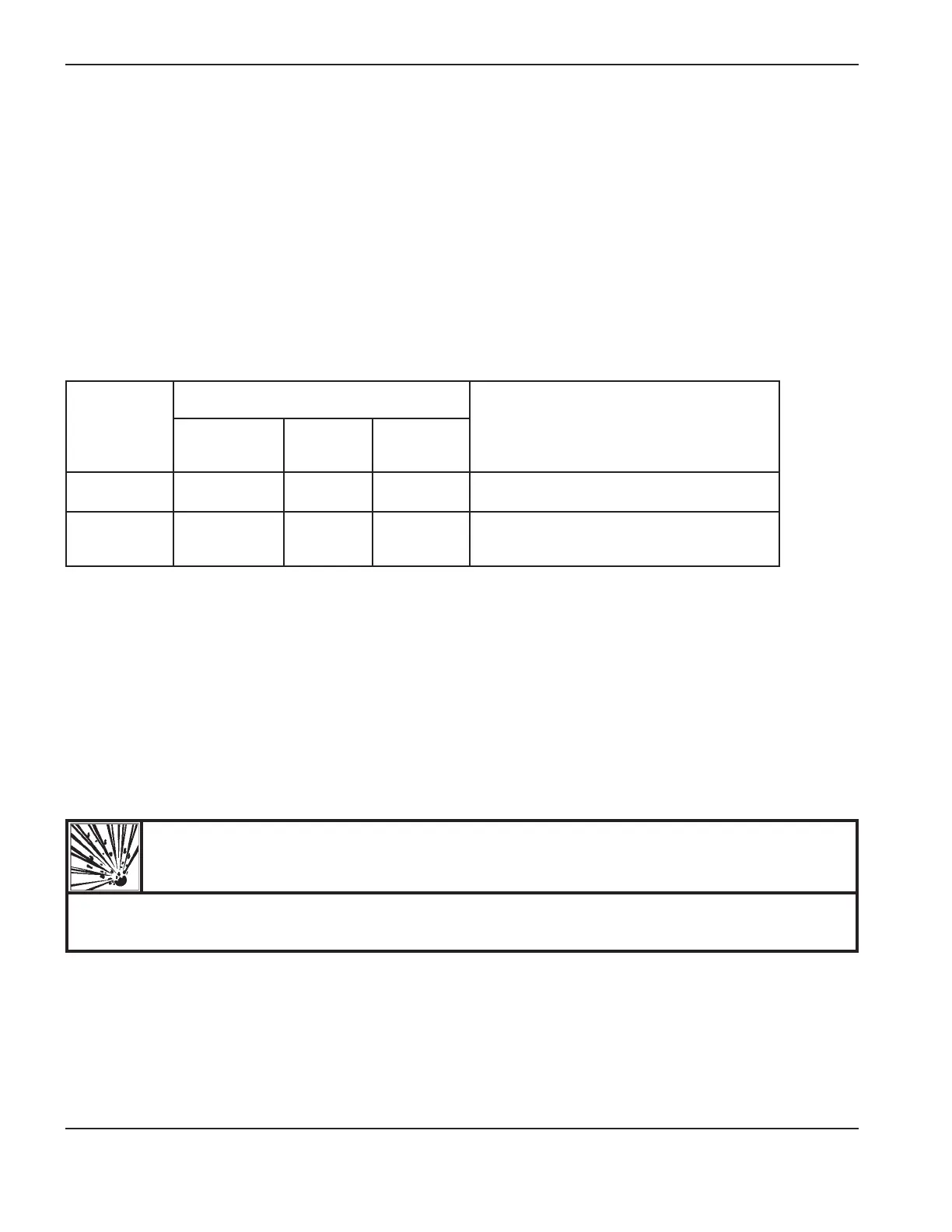

Engine

driverating

Engine drive outputcurrent

Performance

(arc stretch)

1-phase

(CSA/CE)

3-phase

(CE)

3-phase

(CSA)

8 KW 33 A 11.5A 10A Good arc stretch at 45A cutting current

6 KW 25 A 9A 7A

Limited arc stretch at 45A cutting current

Good arc stretch at 30A cutting current

Notes: Based on the generator rating, age, and condition, adjust the cutting current as needed.

If a fault occurs while using a generator, turning the power switch quickly to OFF and then to ON again

(sometimes called a “quick reset”) may not clear the fault. Instead, turn the power supply off and wait 30 to

45seconds before turning it on again.

Prepare the gas supply

The gas supply for the Powermax45 can be shop-compressed or cylinder-compressed.A high-pressure regulator must

be used on either type of supply and must be capable of delivering gas to the filter on the power supply at 170l/min at

6.2bar (360scfhat90psi).

WARNING

Do not allow the gas supply pressure to exceed 9.3 bar (135 psi). The filter bowl may explode if this

pressure is exceeded.

If gas supply quality is poor, cut speeds decrease, cut quality deteriorates, cutting thickness capability decreases, and

the life for consumables shortens. For optimum performance, the gas should have a maximum particle size of 0.1micron

at a maximum concentration of 0.1mg/m

3

, a maximum dew point of -40°C (-40°F), and a maximum oil concentration of

0.1mg/m

3

(per ISO8573-1 Class1.2.2).

Loading...

Loading...