4-1

MAINTENANCE

SFC BOILER / WATER HEATERS - SFC 199

4.0 MAINTENANCE

4.1 UNIT MAINTENANCE

4.1.1 General Care

•

Keep combustible materials and ammable liquids and vapors away from the unit.

• Keep vent terminals clear of obstructions (snow, dirt, etc.).

4.1.2 Inspection

Inspection of the unit is to be performed annually by a qualied service

technician.

4.1.3 Venting

• Check vent terminals for any obstructions (e.g. leaves, dust, other debris).

• Check and clean or replace intake screens as required.

• Check for holes or leaks in venting. Replace venting as needed.

• Examine for any signs of moisture caused by sweating intake air pipes.

Insulate as required.

• Ensure proper resealing or reinstallation of venting at each servicing.

4.1.4 Condensate Trap

• Examine the condensate trap every two months to see if cleaning is

necessary (refer to trap cleaning instructions, section 1.5.3 of this manual).

Ensure that the trap has been re-lled completely before ring the unit.

• Check the pH level of the condensate discharge if using condensate

neutralization.

4.1.5 Burner

• At the rst annual service, remove the burner to inspect the extent of fouling

(refer to burner removal and reassembly instructions, section 3.4.1 of this

manual). Blow clear using compressed air. Evaluate the magnitude of clearing

required, and establish a reasonable burner inspection schedule. Some

installations may call for annual service, others showing clean burners will

only need attention every 2 years. In alternate years, visually inspect burner

through the sight glass. Ensure the ame is stable and without excessive

uttering. Normal ame pattern is evenly distributed over the burner surface.

• If the burner is operating improperly, remove and clean or replace. Use a CO

2

analyzer to determine proper combustion. See Table 12 for correct values.

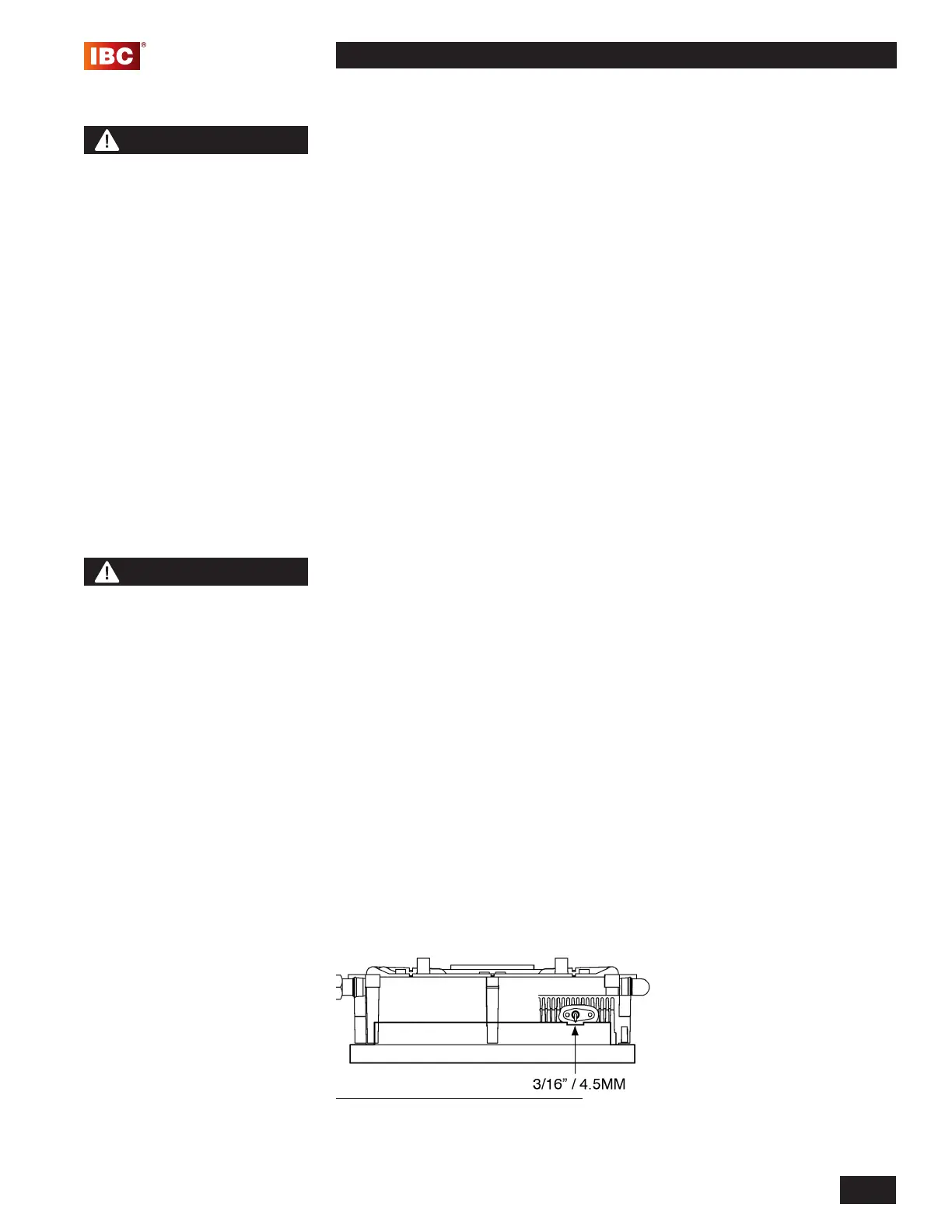

Figure 46: Ignitor Gap - 3/16” / 4.5mm

CAUTION

- The owner is responsible

for general care of the unit.

Improper maintenance of the

unit may result in a hazardous

condition.

- Periodic inspection of the

low water cut-off device,

including ushing of oat

types, is required, if installed

as an accessory to the unit.

- When servicing controls,

label all wires prior to

disconnection. Wiring errors

can cause improper and

dangerous operation.

WARNINGS

- Fill the trap with water

before the unit is rst red to

prevent exhaust fumes from

entering the room. Never

operate the unit unless the

trap is lled with water.

Failure to comply will result in

severe personal injury or death.

-

Whenever the burner is

removed for inspection or

unit servicing, examine the

sealing gaskets and replace if

damaged.

Loading...

Loading...