Loading...

Loading...

Do you have a question about the IDEAL Mexico RS 3/100 and is the answer not in the manual?

Details of optional kits like Programmer, Pump, and Overheat Thermostat.

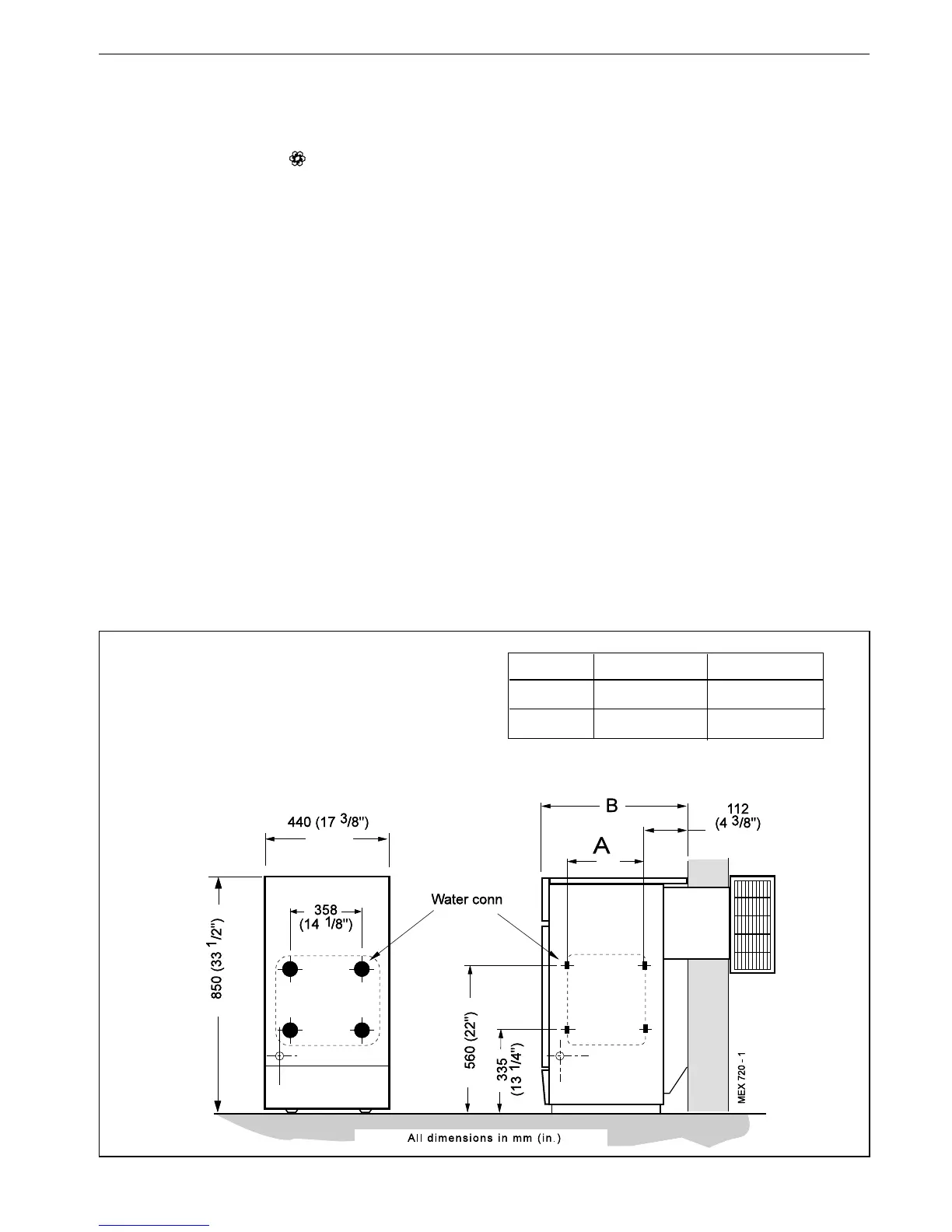

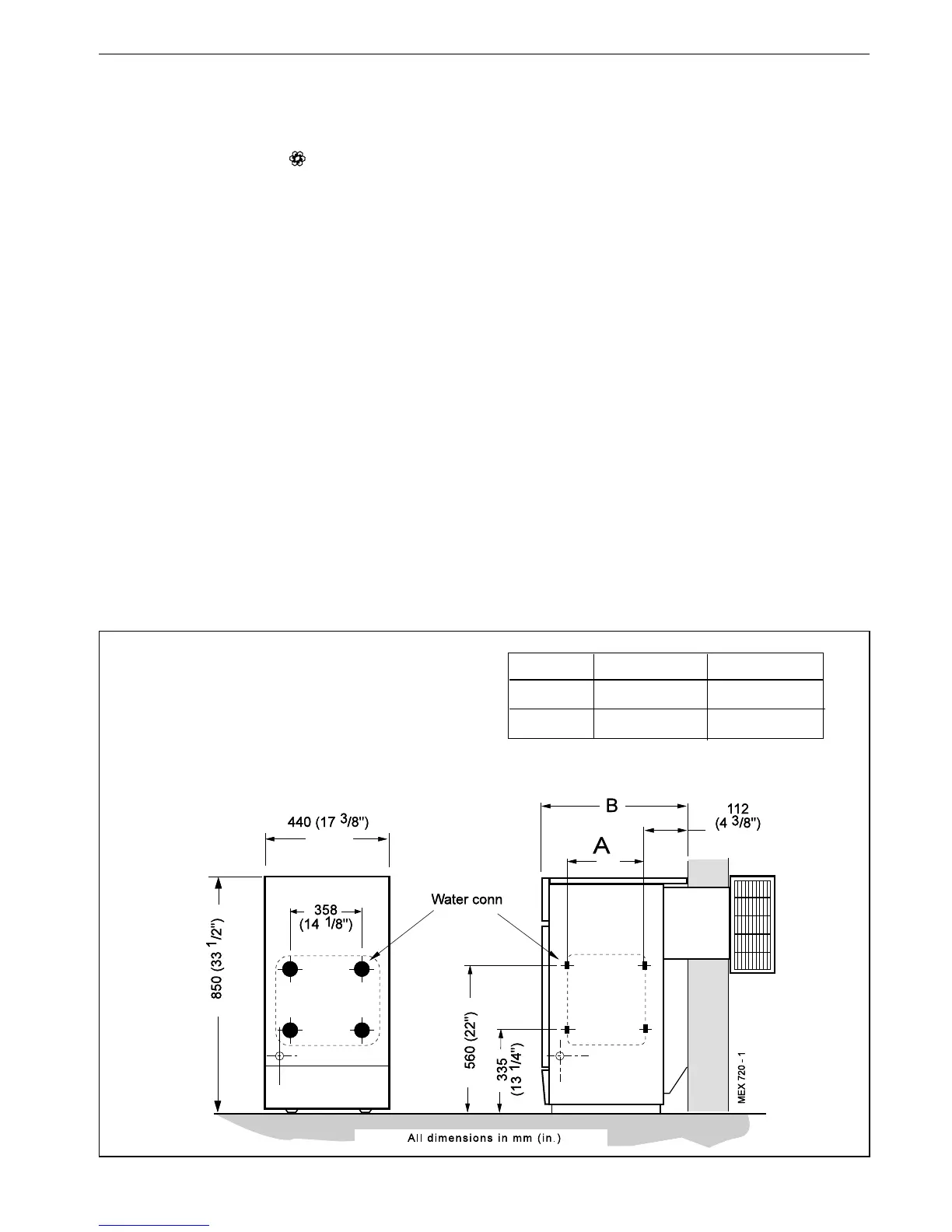

Requirements for boiler placement, including floor and environmental considerations.

Information on connecting the boiler to water systems and potential kits.

Guidelines for boiler placement in bathrooms, compartments, and required clearances.

Guidance on installing the flue system and terminal positions.

Guidelines for ensuring adequate air supply for the boiler's operation.

Guidelines for connecting the boiler to central heating and DHW systems.

Advice on using thermostatic radiator valves and room thermostats for efficient heating.

Requirements for earthing, mains supply, and isolation methods for the boiler.

A list of numbered components shown in the exploded view of the boiler assembly.

Details of the main boiler assembly and included documentation.

List of fittings and components found in the hardware pack.

Items included in the flue packs (B, B1, C) and extension pack (D).

Instructions on how to safely remove the boiler casing panels for installation.

Guidance on preparing boiler connections for pumped and gravity systems.

Instructions for cutting wall openings and sealing flue terminals.

Instructions for installing the flue assembly with standard duct lengths.

Guidance on fitting extension ducts for flue lengths exceeding 400 mm.

Specifications for gas pressure, supply pipes, and installation testing.

Guidance on water pipework, valve settings, and system requirements for pumped systems.

Requirements for mains supply, earthing, and wiring standards for safe electrical connection.

Instructions for making internal electrical connections within the control box.

Guidance on wiring external controls and overview of pictorial wiring diagrams.

Wiring diagrams for mid-position and two spring closed valve heating systems.

Wiring for gravity HW and pumped CH systems using Honeywell 'C' Plan.

Instructions for frost protection wiring and fitting the boiler casing.

Procedures for ensuring electrical safety and gas soundness before operation.

Step-by-step guide for lighting the pilot and main burners.

Procedure for checking gas soundness around the pilot burner connection.

Verifying programmer, thermostat, and flame failure device operation.

Explaining boiler operation, controls, and maintenance to the customer.

Routine checks and servicing recommended for safe and efficient boiler operation.

Step-by-step guide to removing the boiler casing for servicing procedures.

Steps for removing, cleaning, and re-assembling the burner and controls.

Guide for cleaning flueways and reassembling the boiler after servicing.

Procedures for adjusting gas pressure and general component replacement safety.

Instructions for replacing the sightglass and piezo unit.

Steps for replacing the pilot burner, electrode, and ignition lead.

Procedure for replacing the boiler's control thermostat and phial.

Steps for replacing the boiler's control panel and associated wiring.

Procedure for replacing the overheat thermostat and checking its operation.

Instructions for replacing ignition electrode and thermocouple.

Procedure for replacing the main burner and its associated injector.

Steps for replacing main burner injectors with correct jointing compound.

Procedure for replacing the gas valve, ensuring correct orientation and seals.

Troubleshooting steps for pilot ignition and flame stability problems.

Diagnostic steps when the pilot is lit but the main burner fails to ignite.

A detailed exploded view and legend of the burner and controls assembly.

Exploded view and legend of the boiler's control panel components.

Exploded view and legend of the boiler casing assembly parts.